A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 6

6 4

FEATURE

14

the cooling rate during spray quenching is severe, the main

transformation in this study is austenite to martensite.

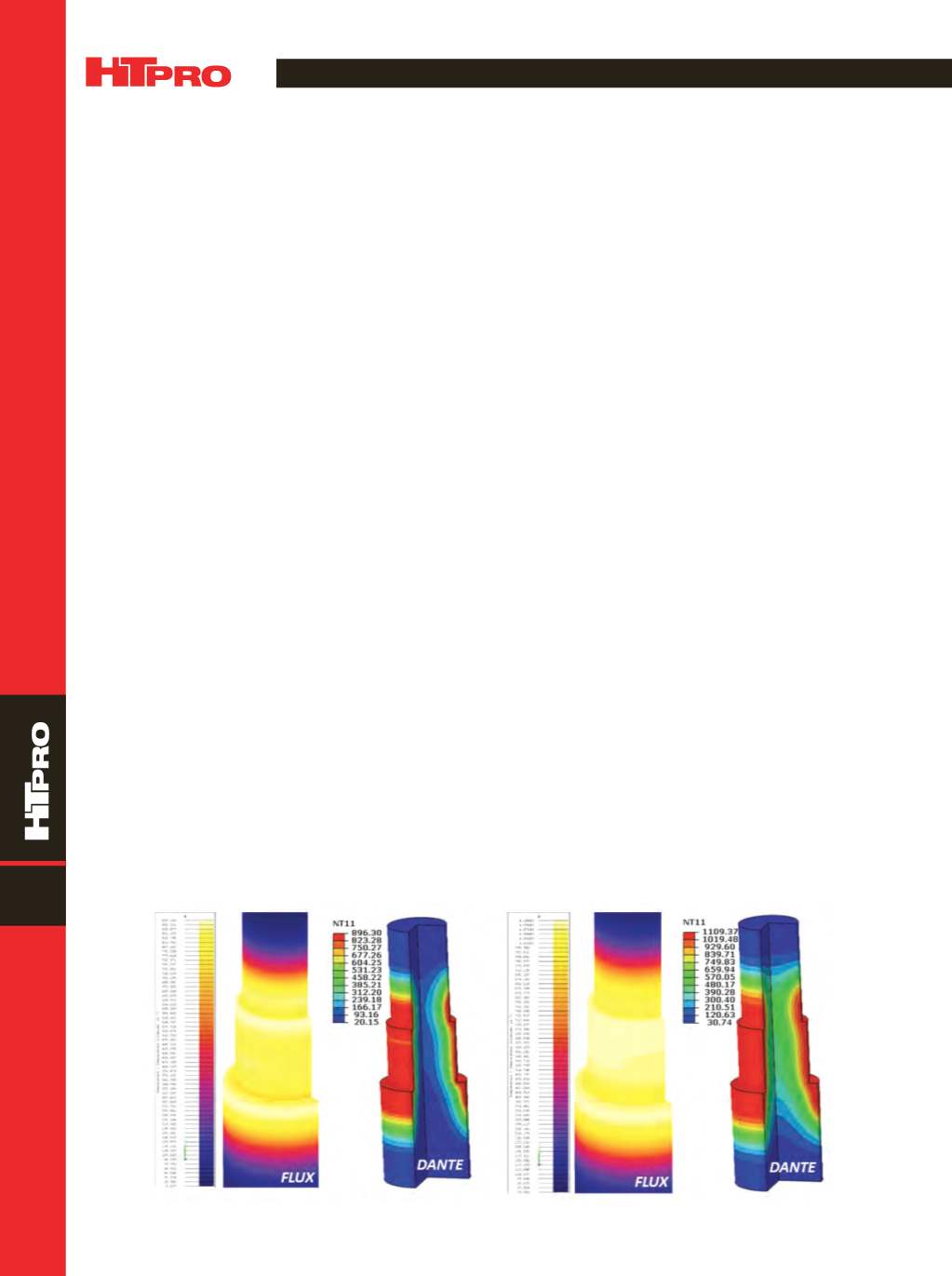

Using Flux-3D, the electromagnetic problemwas solved

and 3D heat source distribution was obtained at different

heating stages. The finite element model is shown in Fig. 3(a).

Calculated power distribution from the Flux-3D model was

mapped into the Dante model for thermal, phase transfor-

mation, and stress analyses; the Dante mesh is shown in

Fig. 3(b). After inductionheating, the shaftwas sprayquenched

usingapolymersolutionwithoutdelay.Differentfiniteelement

mesheswere used for the Flux andDantemodels.

MAPPING FROM FLUX-3D TO DANTE

Copper inductor profiling was optimized and the most

appropriate locations for magnetic flux concentrators were

determined to address changes in shaft geometry. During

the hardening process, the shaft was positioned inside the

inductor with a rotation rate of five rotations/second, and

a total heating time of five seconds, which translates into

25 full rotations during the heating cycle.

Because temperature distribution is relatively uniform

circumferentially in the shaft, a 2D axisymmetric model was

used in Dante to model temperature, phase transforma-

tion, and stress evolution during heating and quenching.

Power distribution in terms of time predicted by Flux-3D

was mapped into the Dante heat treatment model. A special

mapping subroutine was developed because different finite

elementmesheswere used in the Flux-3DandDantemodels.

A comparison of temperature profiles projected by Flux-3D

and Dante reveals good correlation (Fig. 4).

STRESS AND PHASE TRANSFORMATION

MODELING USING DANTE

Temperature, austenite pattern, axial displacement,

radial displacement, and hoop stress distributions after two

seconds of heating are shown in Fig. 5. At the early stage of

heating before the surface transforms to austenite, the sur-

face is under compression due to thermal expansion. After

the surface transforms to austenite, the stress decreases to

amagnitude close to neutral. Compression occurs under the

austenite layer due to thermal expansion, with tensile stress

in the core to balance the stress.

Figure 6 shows predicted results at the end of the five

seconds of heating; the austenite layer is approximately

5 mm deep. Surface temperature is about 1100°C, and the

radial displacement of the heated region is about 0.2 mm.

After heating is complete, the shaft is spray quenched

using a 6% polymer solution; a convection coefficient of

15 KW/(m

2

K) is applied on the shaft surface of the FEA model

to represent the spray quench. After two seconds of quench-

ing, surface temperature is about 204°C, which is below the

M

s

(320°C) of AISI 4140, and martensite formation started

on the surface (Fig. 7). Surface stress shifts from tension to

compression due to the volume expansion that accompa-

nies martensite formation. Surface stress is tensile due to

thermal shrinkage caused by quenching prior to martensite

formation.

At about 10.4 seconds of quenching, almost all of the

austenite layer transforms to martensite (Fig. 8). The surface

temperature is about 70°C and core temperature is about

306°C. Hoop stress on the surface is about −310 MPa under

compression, a tensile stress of about 390 MPa is observed

under the austenitized layer, and the core is under slight

compression of -80 MPa.

Cooling of the core after phase transformation is com-

pleted has a significant effect on the change in stresses

in the shaft. Hoop stresses are −700 MPa at the surface,

+450 MPa at the case-core location, and +150 MPa in the core

after the shaft cools to room temperature (Fig. 9). Resid-

ual stress distribution affects shaft fatigue performance.

Fig. 4 —

Predicted temperature distributions between Flux-3D and Dante during induction heating at 2 s (a) and 5 s (b).

(a)

(b)