A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 6

6 2

FEATURE

12

COMPUTER MODELING SINGLE-SHOT INDUCTION

HARDENING OF A POWER TRANSMISSION SHAFT

Computer modeling is used in induction hardening process design to improve component

quality including hardness, beneficial stress distributions, and reduced distortion.

Zhichao (Charlie) Li*

and

B. Lynn Ferguson, FASM,*

Dante Solutions Inc., Cleveland, and

Collin Russell*

and

Valery Rudnev, FASM,*

Inductoheat Inc., Madison Heights, Mich.

T

he automotive industry is implementing lightweight-

ing initiatives invehicledesign tomeetmorestringent

federal Corporate Average Fuel Economy regulations.

New component designs involve material removal result-

ing in complex geometries containing longitudinal and/

or transverse holes, grooves, shoulders, flanges, diameter

changes, undercuts, teeth, splines, andmore. Many of these

components with complex shapes are surface hardened

using induction hardening (Fig. 1). Four induction methods

routinely used are scan, continuous or progressive, static,

and single shot hardening

[1]

.

Irregularities in component geometry distort the mag-

netic field generated by an inductor, which can cause tem-

perature deviations, hot and cold spots, excessive shape

distortion, undesirable microstructures, grain boundary

liquation, and cracking. For example, scan hardening shafts

with large shoulders, multiple diameter changes of apprecia-

ble size, and other irregularities can produce severe nonuni-

formhardened patterns. Eddy current flow and temperature

fields should be evaluated to determine appropriate process

parameters and coil design to prevent cracking and mini-

mize distortion.

Steel shafts and shaft-like components are traditionally

induction surface hardened using scanning and single-shot

methods. In the single-shot method, the part rotates rather

than the shaft or coil moving relative to each other. The

entire region to be hardened is heated at the same time.

Single-shot inductors

typically control hardness pattern and

distortion better than scan and static hardening, particularly

for stepped shafts. A single-shot inductor consists of two

legs and two crossover segments. Crossover segments encir-

cle only half of the workpiece circumference, and induced

eddy currents primarily flow along the length of the part. An

exception is crossover segments where eddy current flow is

half circumferential. Longitudinal leg sections are profiled by

relieving selected regions of the copper inductor to accom-

modate workpiece geometrical features, such as changes in

diameter and undercuts.

Inductor configuration depends on factors such as

workpiece geometry, temperature uniformity, required

hardness pattern, and production rate. The designmust take

into account the tendency of certain geometrical features to

produce heat surpluses and/or heat deficits upon induction

heating. Required heat source control can be achieved by

adjusting the current-carrying face of the appropriate induc-

tor section, applying flux concentrators, and by varying the

inductor-to-workpiece gap. Determining the appropriate

inductor profilemight be cumbersome and time-consuming.

For critical applications, single-shot inductors are CNC

machined from solid copper to conform to the area of the

part to be heated. This type of inductor requires the most

care in fabrication because it usually operates at high power

densities, and workpiece positioning is critical with respect

to coil profile. Single shot hardening is also the preferred

*Member of ASM International

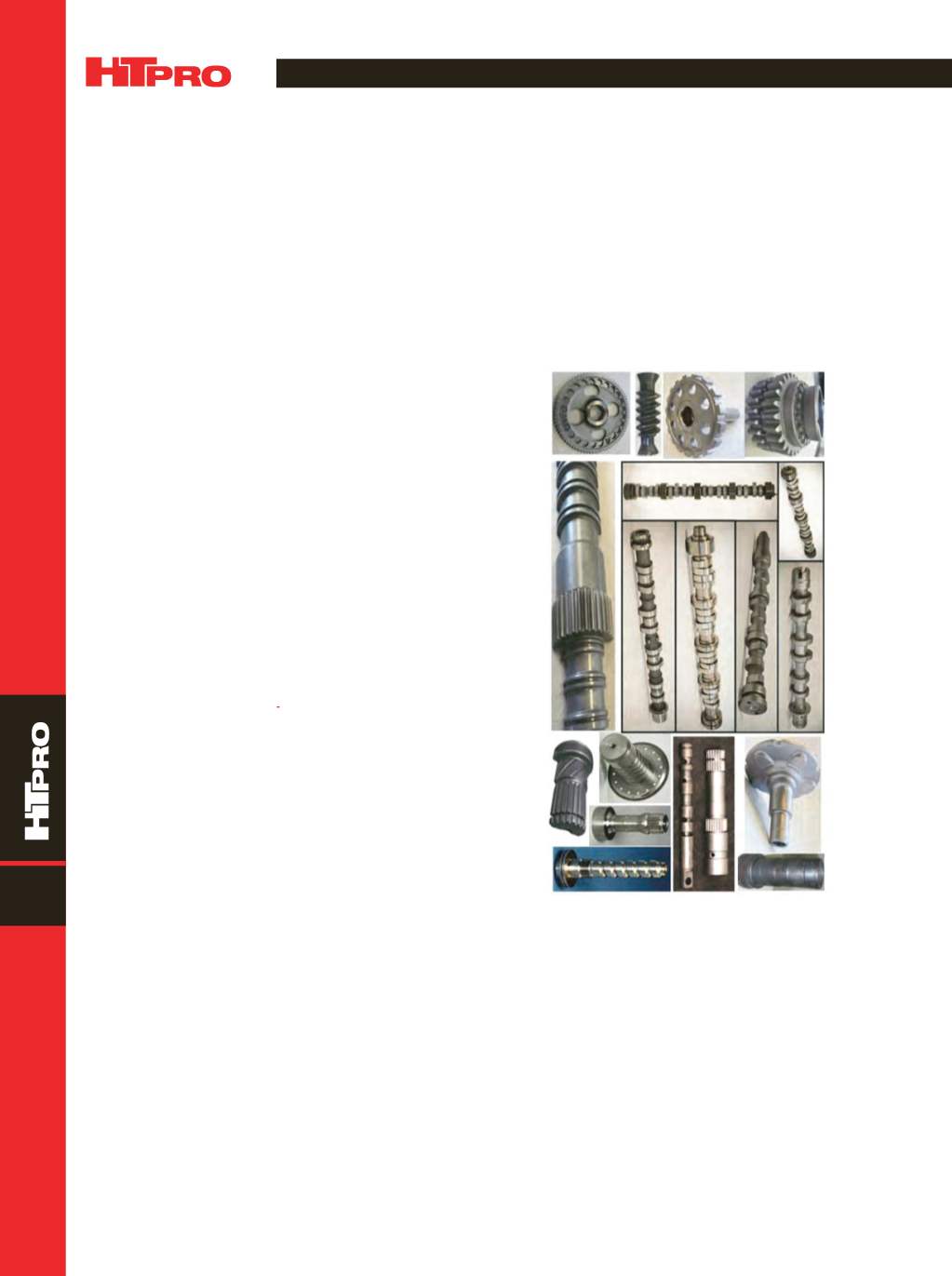

Fig. 1 —

Variety of complex geometry components that are rou-

tinely induction hardened.