A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

N O V E M B E R / D E C E M B E R

2 0 1 6

6 3

FEATURE

13

choice when shorter heat times/high production rates are

desired. Heating time can be as short as two seconds, but is

typically four to eight seconds. Sufficient rotation is critical

with single-shot inductor design; at least 10 full rotations per

heat cycle is desired. Spray quenching can begin immedi-

ately after austenitization is complete, or after a short delay.

The duration of quench delay can range from a fraction of a

second to a few seconds depending on the geometry of the

component, material chemical composition, and hardness

pattern specification.

COMPUTER MODELING SPECIFICS

The current production environment does not allow

the luxury of process design via trial and error. Computer

simulation enables induction heating specialists to quickly

determine process details, which could be costly, time con-

suming, anddifficult or impossible to resolve experimentally.

Simulation enables prediction of how different interrelated

and nonlinear factors could impact the transitional and final

thermal conditions of the heated component. It also helps

determine what must be accomplished to improve process

effectiveness to establish the most appropriate process rec-

ipes. Computer modeling provides a comfort factor when

designing new systems, avoids unpleasant surprises, short-

ens the learning curve, and reduces development time.

Today, most software programs are not capable of

modeling single shot hardening. However, FEA software

developed by Dante Solutions in combination with propri-

etary subroutines for Flux-3D developed by Inductoheat

enable taking into consideration all critical features of the

induction hardening process

[2]

.

MODELING INDUCTION HARDENING

OF ASTEEL SHAFT

Consider a case study of induction hardening of an AISI

4140 alloy steel shaft with shoulders and numerous changes

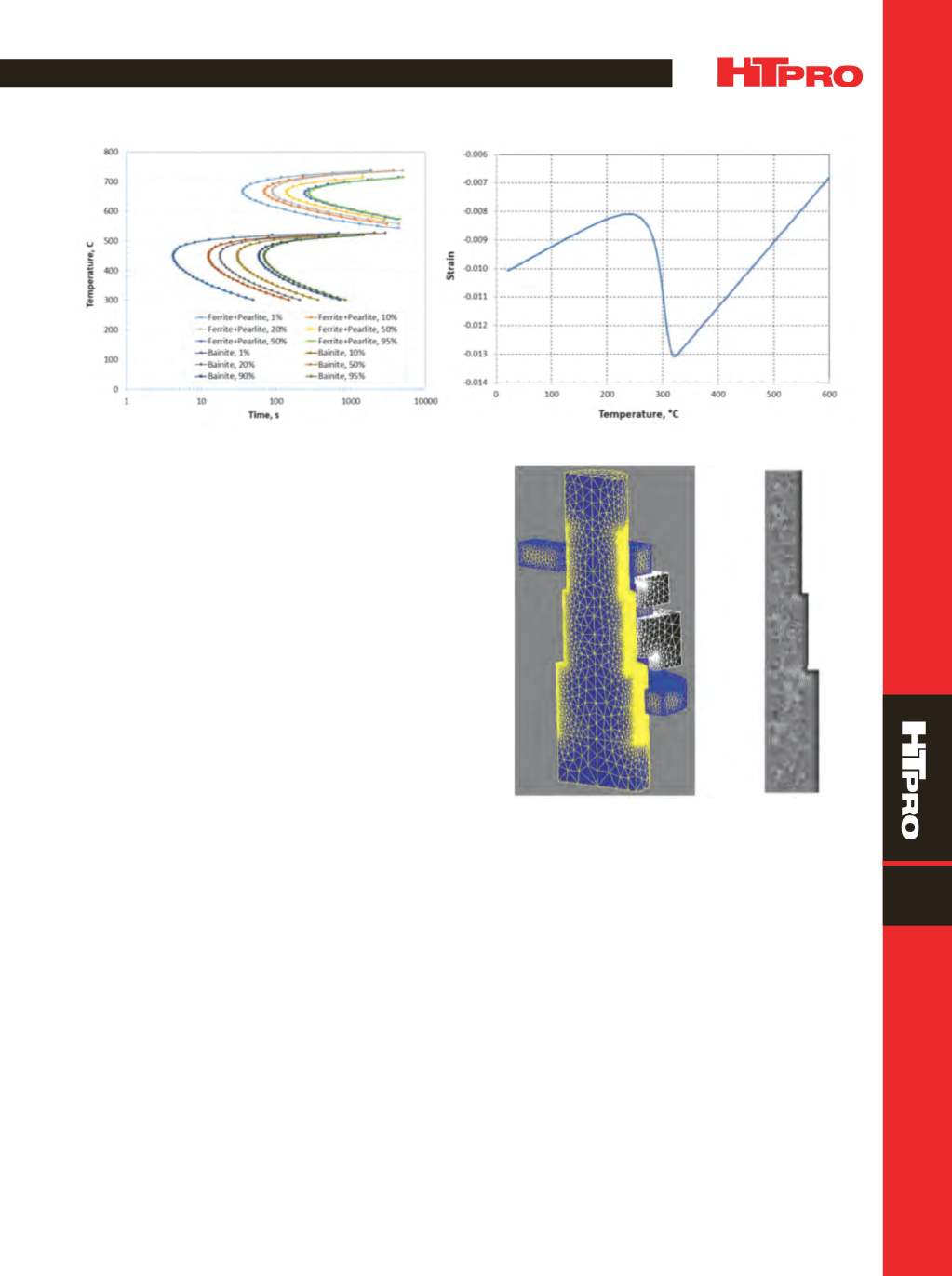

Fig. 2 —

TTT diagram (a) and dilatometry strain curve (b) of martensite transformation for AISI 4140 generated fromDante database.

Fig. 3 —

Finite element models: (a) electromagnetic model used

by Flux-3D, and (b) 2D axisymmetric model used by Dante.

in diameter. Phase transformations occur during induction

heating and spray quenching. The surface of the part trans-

forms to austenite during heating, and during quenching,

austenite can transform to ferrite, pearlite, bainite, or mar-

tensite depending on the cooling rate. Accurate descriptions

of phase transformations and mechanical properties of

individual phases are required for thermal stress analysis

[3]

.

Figure 2(a) shows the TTT diagram of 4140 generated from

the Dante database. The TTT diagram is not used in Dante

models directly, but the analytical phase transformation

models and database contain all TTT diagram information.

Figure 2(b) shows a dilatometry strain curve during marten-

site formation under continuous cooling. The curve provides

themartensite start temperature (M

s

), martensite finish tem-

perature (M

f

), transformation strain, and coefficients of ther-

mal expansion (CTE) for austenite and martensite. Because

(a)

(b)

(a)

(b)