A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 6

6 0

FEATURE

10

operating condition. Aligned with the overall Industry 4.0

vision, these changes would also make heat treating more

operationally efficient with robust, quality products.

INDUSTRY4.0: HEATTREATINGSTORYBOARDS

Three examples of Industry 4.0 will now be illustrated

for heat treating operations, described in an IoT framework

with key characteristics of sensing, connectivity, analytics

and intelligence capabilities, and business value:

Recipe management:

Although significant changes in

furnace technology and automation have occurred, the heat

treating recipe—which is the core of heat treating opera-

tions—continues tobeheuristicallydeveloped. Furthermore,

recipe selection for new parts is also heuristic, resulting in a

significant amount of rework and reject levels at initial stages

of production. It is expected that Industry 4.0would have the

most significant impact on how heat treating recipes are

developed and managed. Recipe selection would primarily

be accomplished through image recognition algorithms of a

part, which would eliminate mistakes in selection. Further,

self-learning algorithms would enable continuous evolu-

tion of recipes with feedback from historical quality data

(Fig. 4). This would also enable recipe customization based

on the current part chemistry and furnace health and oper-

ating condition. The system would also have self-evolving

capabilities for heat treating recipes to become rationalized

(Fig. 5) over time due to changes in product mix. Any recipe

decision due to production disruption in pre- or post-steps

could be better managed. Consequently, heat treating oper-

ations will be more efficient and product quality will be pre-

dictable. In the Industry 4.0 framework, heat treaters need:

sensing capability for part shape, quantity, and weight in the

furnace; connectivity and analytics capability to choose the

correct reference recipe; intelligence capability to fine-tune

the recipe based on instantaneous inputs and operating

conditions; and long-term rationalization and recipe devel-

opment to create value in terms of efficient operations and

robust product quality.

Distortion control:

Distortion control in precision trans-

mission components, such as gears and shafts, is a signifi-

cant heat treating challenge. Critical parameters including

chemistry (Fig. 6), process parameters during reheating

and forging, annealing and machining conditions, and car-

burizing and quenching conditions impact distortion. A key

reason for distortion is inadequate information at different

processing steps, which prevents efficient distortion-man-

agement strategies. For example, chemical composition is

directly linked to hardenability and distortion. Significant

control of distortion could be achieved if information on

the composition is known at the heat treating step, and an

instantaneous recipe created incorporating this information.

Further, depending on quench-tank conditions and furnace

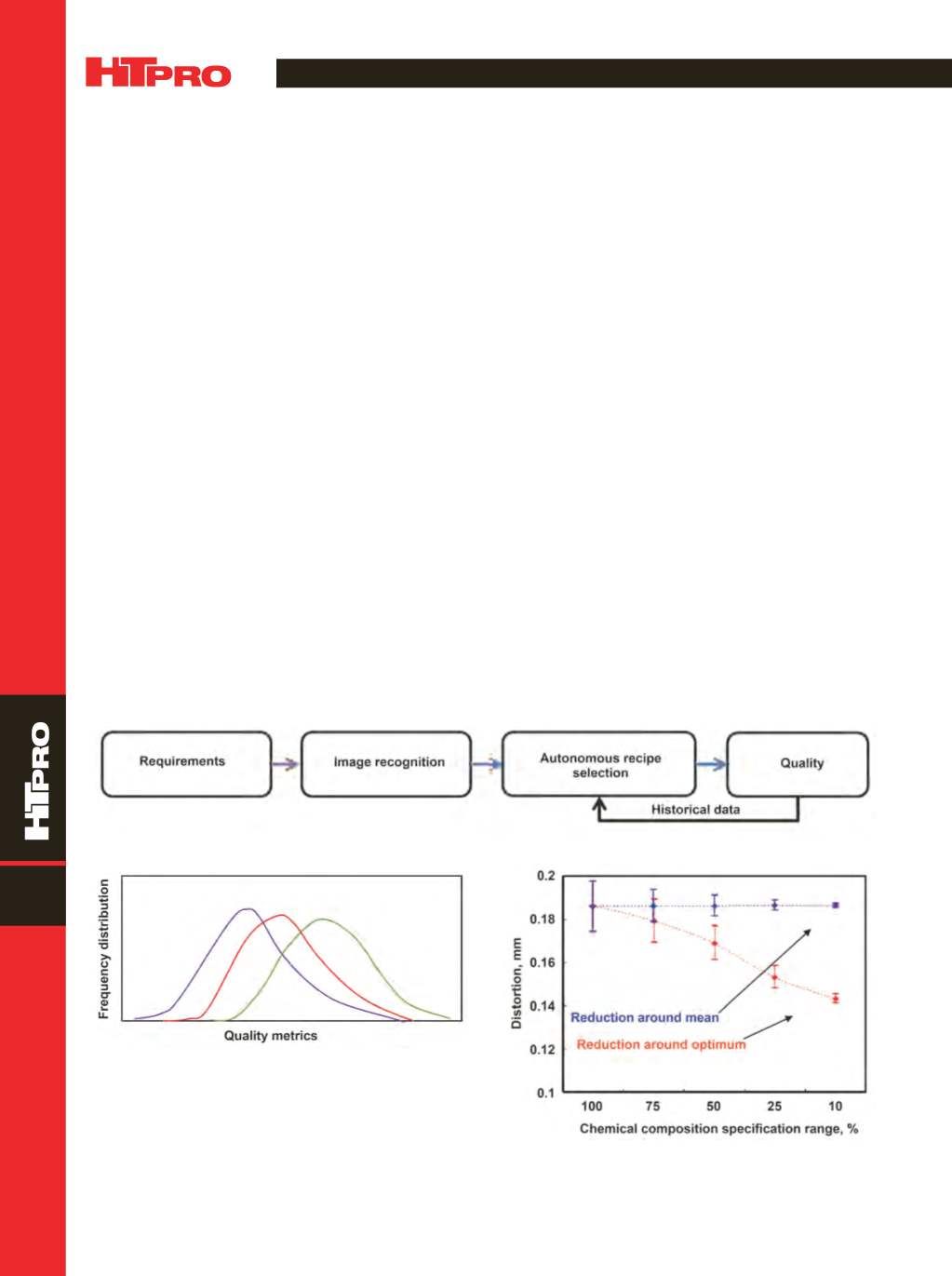

Fig. 4 —

Self-learning algorithms and intelligence created for autonomous recipe selection, management, rationalization, and fine-tuning.

Fig. 5 —

Overlapping frequency distributions of quality metrics

obtained fromdifferent recipes indicate the possibility of recipe

rationalization.

Fig. 6 —

Influence of steel chemical composition (within specified

chemistry range) on heat treating distortion, which presents an

opportunity to control distortion by fine-tuning recipes for specific

loads.