A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A R C H

2 0 1 6

2 3

BSS series from Boeing and the AITM

series from Airbus. Finally, some obso-

lete standards are still in use, such as

those published by the Suppliers of Ad-

vanced Composite Materials Association

(SACMA) and the Composites Research

Advisory Group (CRAG).

CONCLUSION

Composite materials offer great

potential for future generations of

lightweight, environmentally friendly

vehicles. These materials are complex

and comprehensive data is needed for

design and modeling. Although a range

of mechanical tests is required to ob-

tain data, the aerospace industry has

already developed, validated, and stan-

dardized these test methods—and the

automotive industry can benefit from

this effort.

~AM&P

For more information:

Ian McEnteg-

gart is composites marketing manager,

Instron, 825 University Ave., Norwood,

MA 02062,

ian_mcenteggart@instron. com, www.instron.com.

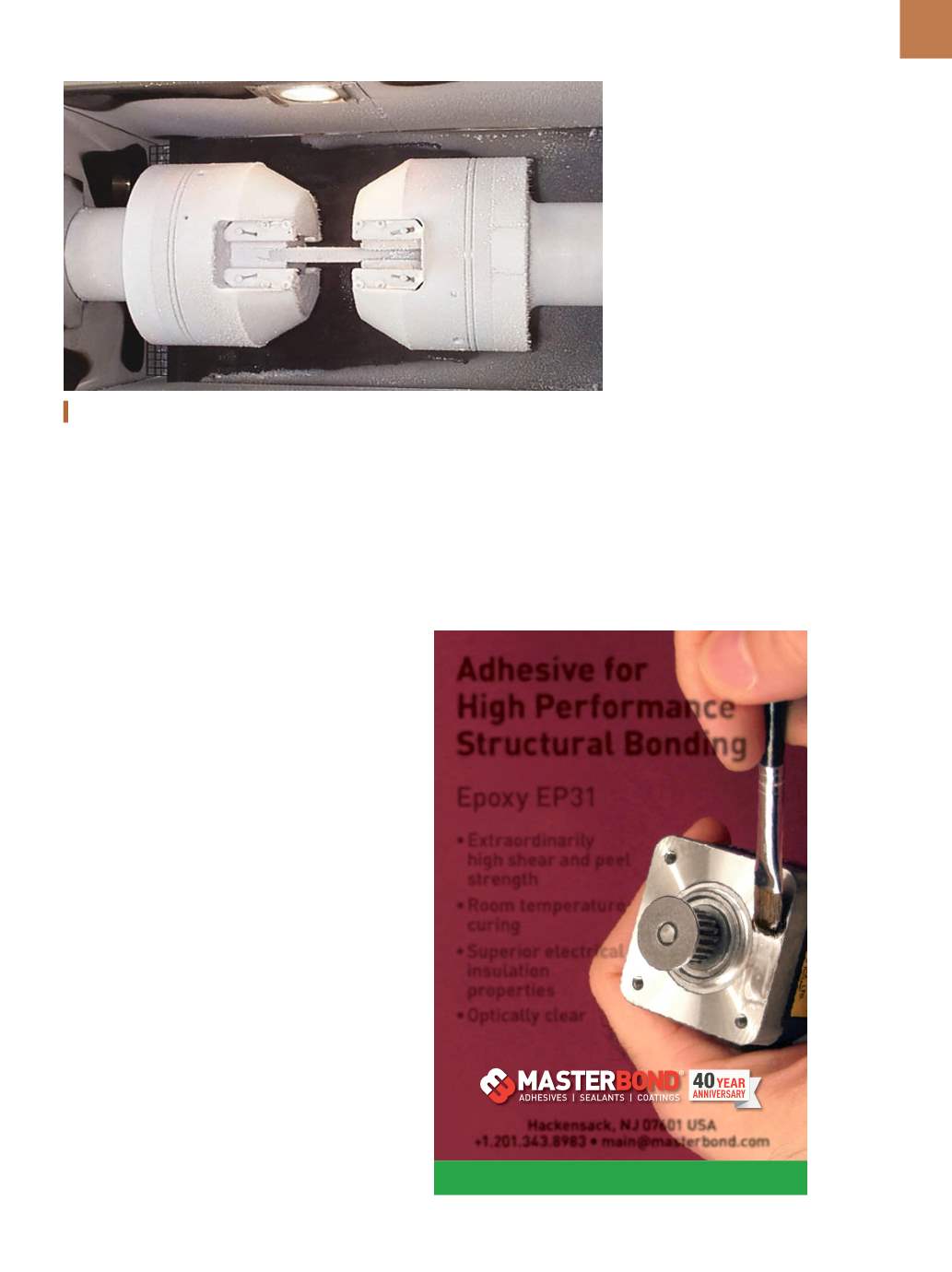

Low-temperature testing in an environmental chamber.

or hydraulically driven indenter. After

impact, damage is evaluated by either

visual or ultrasonic inspection and/or

determination of residual strength in a

compression after impact (CAI) test. In

a CAI test, an impact-damaged compos-

ite panel is mounted in a support to pre-

vent buckling and loaded in compres-

sion until it fails. High-rate tension or

compression testing can be performed

either using a drop tower with a high-

speed force sensor or with a high-rate

servohydraulic testingmachine. The ser-

vohydraulic machine provides a more

flexible platform for this type of work.

For example, it can test over a wider

speed range and can maintain a con-

stant speed during the test.

CONDITIONING AND

TEST ENVIRONMENTS

The properties of polymer matrix

composites are influenced by environ-

mental conditions. The most common

environmental factors include tempera-

ture and humidity. Testing over a range

of temperatures is normally conduct-

ed inside a temperature chamber with

heating and cooling capability. Evaluat-

ing the effects of humidity requires long-

term exposure of test specimens to a

humid atmosphere in a humidity cham-

ber (a process known as conditioning),

followed by testing. The process of ab-

sorbing and desorbing moisture is slow,

so there is no need to conduct the final

testing in a humid atmosphere.

TEST STANDARDS

The main international composite

testing standards are those maintained

by ASTM, ISO, and CEN (European Com-

mittee for Standardization). In addition

to international standards, a number of

manufacturers’ proprietary standards

are in widespread use including the

• Extraordinarily high shear and peel strength • Room temperature curing • Superior electrical insulation properties • Optically clear Adhesive for High Performance Structural Bonding www.masterbond.com Hackensack, NJ 07601 USA +1.201.343.8983 • main@masterbond.com Epoxy EP311016LK_3.25x4.875_EP31_40yr.indd 1

1/24/16 9:10 PM