A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A R C H 2 0 1 6

1 8

TABLE 1

—

CHEMICAL COMPOSTIONS OF COMMERCIAL A380 AND RESEARCH AL ALLOYS, WT%

Alloy

Si

Cu

Mg

Fe

Sr

Mn

Zr

Ti

V

Al

New

7.02

0.95

0.48

0.09

0.012

0.005

0.47

0.21

0.30

Bal

A380

9.5

3.4

0.07

0.90

<0.001

0.18

0.0073 <0.001 0.0087

Bal

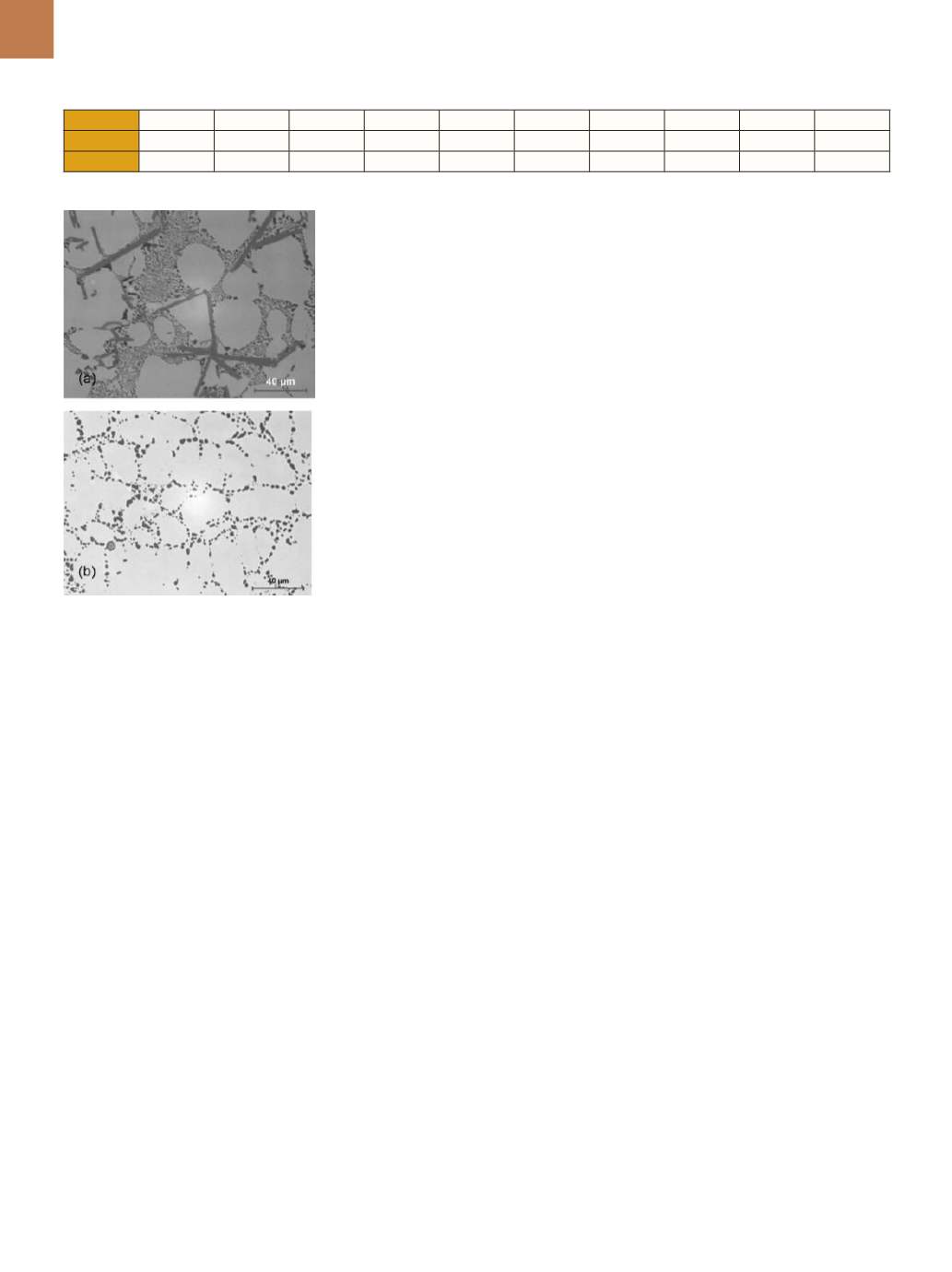

Fig. 2 —

(a) As-cast microstructure of re-

search alloy; (b) microstructure after T6 heat

treatment. Chemical composition listed in

Table 1.

different lattice parameters. They in-

clude Al

6.7

Si

1.2

TiZr

1.8

, Al

21.4

Si

4.1

Ti

3.5

VZr

3.9

,

and Al

2.8

Si

3.8

V

1.6

Zr, which are desig-

nated in the literature as (AlSi)

3

(TiZr),

(AlSi)

3

(TiVZr),

and

(AlSi)

2

(VZr),

respectively.

Another positive modification of

the alloy microstructure occurs in the

Fe-containing

β

-Al

5

FeSi phase, which is

generally needlelike in shape and detri-

mental for alloy strength and ductility.

As a result of alloying with Zr-Ti-V, the

Fe-containing

β

-Al

5

FeSi phase converts

into the Al

5.1

Si

35.4

Ti

1.6

Zr

5.7

Fe phase with

a general formula of (AlSi)

2

(TiZr)Fe.

Zr always forms complex intermetallics.

The intermetallic phases are distribut-

ed most often in interdendritic regions.

TESTING HIGH-TEMPERATURE

PERFORMANCE

To test high-temperature perfor-

mance, alloys were subjected to var-

ious heating cycles. Test results were

compared with properties of commer-

cial A380 alloy, currently the industry

choice for targeted automotive appli-

cations. As-cast hardness of A380 al-

loy (83 HRF) was over 10 units higher

than that of the research alloy. Results

of isochronal aging at temperatures

up to 500

°

C show that the research al-

loy achieved peak aging hardness at

approximately 200

°

C, and a hardness

difference existed at the peak between

the research alloy and A380 grade

[9]

. For

temperatures up to 150

°

C, A380 experi-

enced a hardness reduction compared

with an increase for the research alloy.

Temperatures of phase stability

were identified using electron micros-

copy, electron backscatter diffraction,

and high-temperature x-ray diffraction.

During the solutionizing step of the T6

heat treatment at 510

°

C followed by

525

°

C, the research alloy primarily ex-

perienced dissolution of Cu-containing

phases (Fig. 2b). Some other phases

including eutectic silicon experienced

only partial dissolution. Some phases

were not affected by the solutionizing

temperature, indicating their high sta-

bility. In-situ x-ray diffraction of bulk

material at room and elevated tem-

peratures is useful to directly test alloy

phase stability. For the research alloy,

increasing the temperature from 200

°

to 400

°

C led to dissolution of the Si eu-

tectics in the Al matrix. Also, Al

2

Cu and Q

phases dissolved with increasing tem-

perature from 300

°

to 500

°

C, and were

not detected by x-ray above 500

°

C. In

contrast, phases containing transition

metals V, Ti, and Zr remained present

up to temperatures between 695

°

and

705

°

C, i.e., after reaching liquid state,

indicating their high stability.

STATIC MECHANICAL

PROPERTIES

Microstructural

modifications

through alloying additions affect work

hardening and texture, tensile and

compressive deformation behavior, hot

deformation, and movement of disloca-

tions during deformation at increasing

temperatures. In automotive engine ap-

plications, Al alloysare subjected tocom-

plex stress scenarios. The component

typically undergoes compression during

heating and is under tension during sub-

sequent cooling. Therefore, hot tensile

and compressive behavior are relevant

for good material performance.

The as-cast research alloy had a

yield strength (YS) of 162 MPa, an ulti-

mate tensile strength (UTS) of 252 MPa,

and an elongation of 3.9% inmonotonic

loading at room temperature. Proper-

ties improved substantially after the T6

heat treatment, resulting in 287 MPa YS,

343 MPa UTS, but lower elongation of

2.6% (Fig. 3a). Compression properties

were 312 MPa YS, compressive strength

of 418 MPa, and a compressibility value

of 52.2% (Fig. 3b). It was established

during compression experiments that

decreasing deformation temperature

in the range of 200

°

to 400

°

C, and to a

lesser extent increasing the strain rate

in the range of 10

-3

– 1 s

-1

, led to higher

flow stress.

During hot compression deforma-

tion, fracturing and reorientation of the

second phase particles occur, and both

phenomena are influenced by tem-

perature and strain rate. For both the

research and A380 alloys, intermetallic

precipitates experience substantially

more frequent cracking than the eu-

tectic silicon. Although second phase

particles in both alloys have a similar

morphology, there is a difference in their

performance during hot compression. In

the research alloy, eutectic silicon and

intermetallics were more resistant and

experienced less frequent fracturing.

Also, both the eutectic silicon and inter-

metallic particles of complex chemistry

are more resistant to rotation within the

matrix during hot deformation.

CREEP PROPERTIES

Creep-rupture tests provide rel-

evant information when considering