A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A R C H

2 0 1 6

1 5

NANOTECHNOLOGY

BRIEFS

Aleris, Cleveland, offers a new 7017 aluminum alloy in North America for commercial plate and defense

uses. After extensive review and testing, the U.S. Army Research Lab issued MIL-DTL-32505 for use in armor

applications. 7017 offers high strength, good weldability, and corrosion resistance. It is currently used in

Europe and Asia on combat vehicles to achieve superior ballistic protection.

aleris.com.

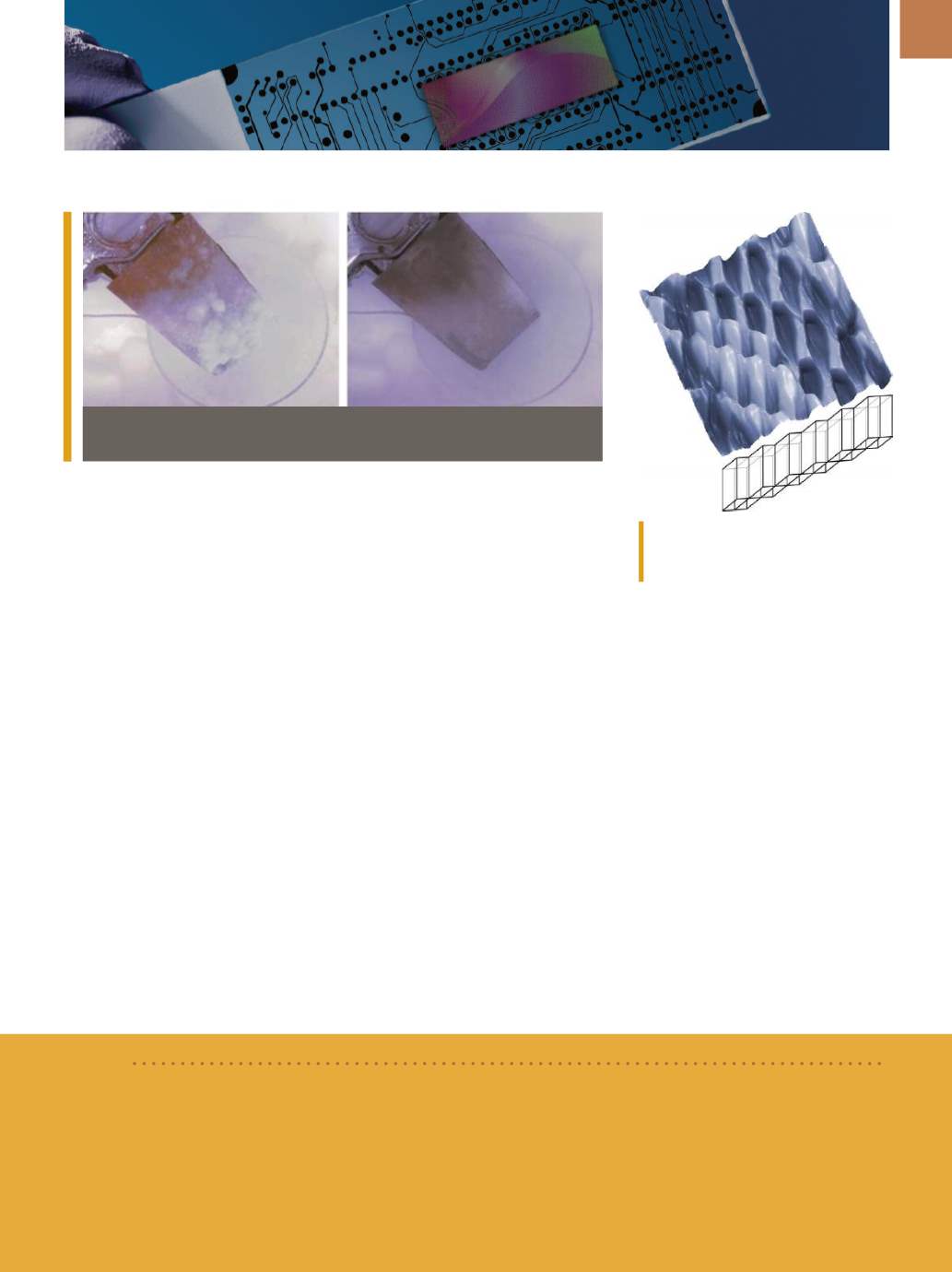

NANORIBBON COMPOSITE

MELTS ICE

Researchers at Rice University,

Houston, developed a thin, conductive

coating that can serve as a real-time

de-icer for aircraft, transmission lines,

and other surfaces exposed to winter

weather. The coating consists of an ep-

oxy lacedwith interconnected graphene

nanoribbons that conduct electricity

across the material, heating the sur-

face and melting ice. The team spread a

thin coat of the composite—consisting

of no more than 5% nanoribbons—on

part of a helicopter rotor blade, then re-

placed the thermally conductive nickel

abrasion sleeve used as a leading edge.

When a small voltage was applied, the

coating delivered electrothermal heat,

or Joule heating, raising the compos-

ite’s temperature to more than 200°F.

This was enough to melt 1-cm-thick ice

on a static blade in a -4°F environment.

For surfaces in motion, the

thin layer of water that forms on the

surface after heating begins should

be enough to loosen and dislodge ice

before it is completely melted. “Apply-

ing this composite to wings could save

time and money at airports where the

glycol-based chemicals now used to

de-ice aircraft are also an environmen-

tal concern,” says chemist James Tour.

Additionally, the coating could help

protect aircraft from lightning strikes

and provide an extra layer of electro-

magnetic shielding.

rice.edu.

NEW NANOSTRUCTURE

DISCOVERED

A previously unknown, 3D nano-

structure consisting of graphene sheets

was discovered by a staff scientist at

the Institute of Physical Problems,

Russian Federation. The new nano-

structure is a multilayer system of

parallel hollow channels with a quad-

rangular cross section extending along

the surface. Though this structure is

unlike anything previously observed

in graphite, the wall thickness of less

Box-shaped graphene—a 3D nano-

structure consisting of graphene sheets.

Courtesy of Rostislav Lapshin.

BRIEF

Defense Advanced Research Projects Agency

(DARPA), Arlington, Va., launched its

Atoms to Product

program to

develop technologies and proc sses for ass mbling na om ter-scale pi c s into sy tems, components, r materi-

als that are at least millimeter-scale in size. DARPA recently selected 10 companie t tackle this challenge: Zyv x

Labs, Richardson, Texas; SRI, Menlo Park, Calif.; Boston Univ rsity; University of N re Dame, South Bend, Ind.; HRL

Laboratories, Malibu, Calif.; PARC, Palo Alto, Calif.; Embody, Norfolk, Va.; Voxtel, Beaverton, Ore.; Harvard University,

Cambridge, Mass.; and Draper Laboratory, Cambridge, Mass. The program calls for closing the assembly gap in two

steps—from atoms to microns and frommicrons to millimeters.

darpa.mil.

than 1 nm and the quadrangular cross

section of the channels clearly indi-

cate that the channel walls/facets are

graphene planes. It is hypothesized

that the structure was formed from a

series of mechanical deformations of

graphite, which is layered by nature.

Because the nanochannels have a

quadrangular cross section, the newly

detected structure is called

box-shaped

graphene

(BSG). Preliminary analysis

indicates that the nanostructure could

be used in applications such as ultra-

sensitive detectors, high-performance

catalytic cells, nanochannels of micro-

fluidic devices, high-performance heat-

sink surfaces, enhanced rechargeable

batteries, and high-capacity sorbents

for safe hydrogen storage.

www.niifp.ru.

Graphene nanoribbon-infused epoxy embedded into a helicopter blade. Courtesy

of the Tour group.