A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A R C H

2 0 1 6

1 1

or suffers a scratch, stress, or fracture,

the capsules break open. The dye reacts

with the epoxy, causing a dramatic

color change from light yellow to bright

red—with no additional chemicals or

activators required. The deeper the

scratch or crack, the more microcap-

sules are broken and the more intense

the color. The team is now exploring

further applications for the indicator

system, such as applying it to fiber-

reinforced composites, as well as

integrating it with previous work in

self-healing systems.

illinois.edu.

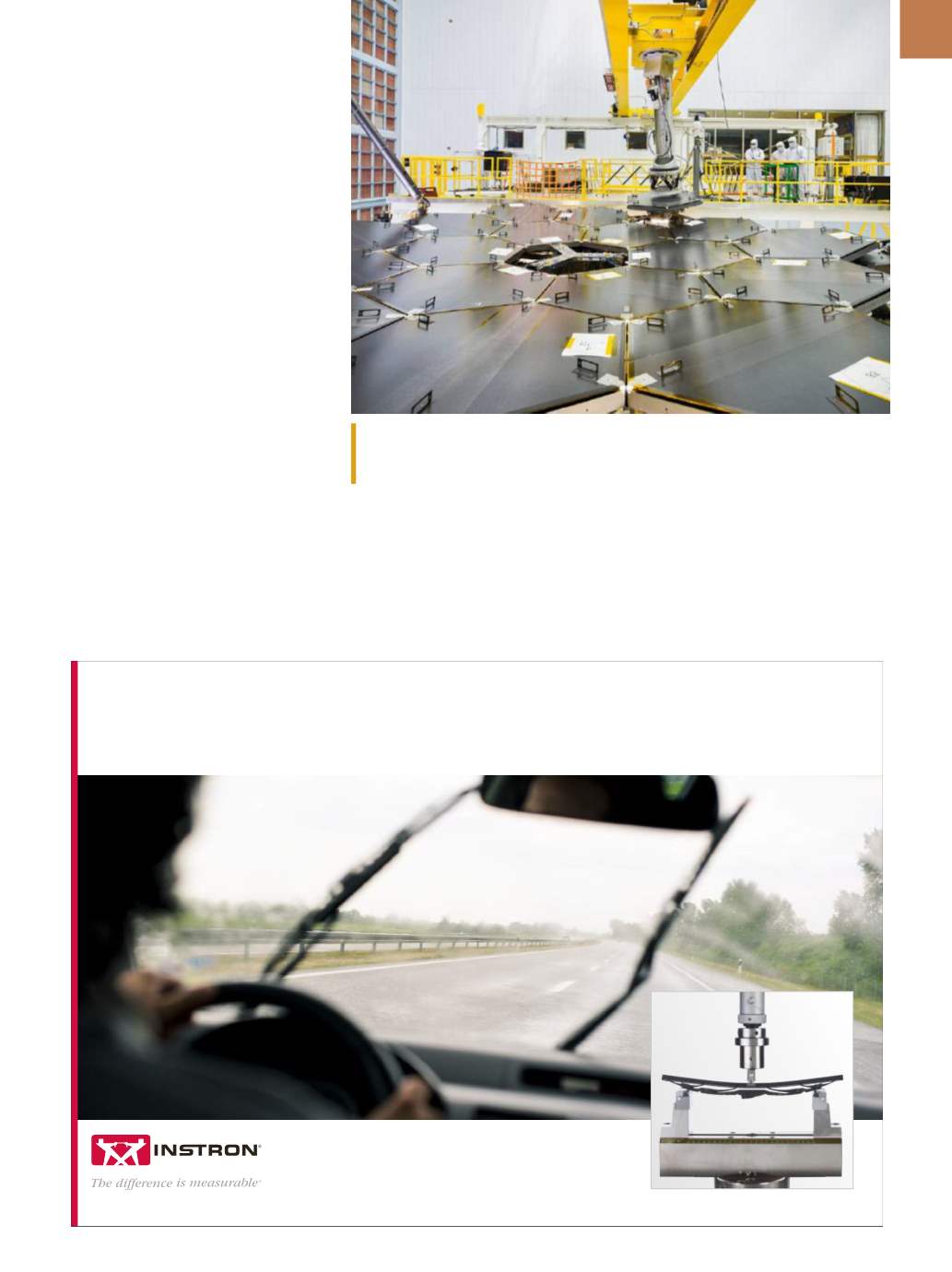

FINAL MIRRORS INSTALLED

ON JAMES WEBB SPACE

TELESCOPE

In February, the 18th and final

primary mirror segment was installed

on the James Webb Space Telescope

at NASA’s Goddard Space Flight Center

in Greenbelt, Md. Using a robotic arm,

the team installed all of Webb’s primary

mirror segments onto the telescope

structure. Each hexagonal-shaped seg-

ment measures just over 4.2 feet across

and weighs approximately 88 pounds.

Once in space and fully deployed, the

segments will work together as one

large 21.3-foot-diameter mirror.

MirrorswerebuiltbyBall Aerospace

& Technologies Corp., Boulder, Colo.,

the principal subcontractor to Northrop

Grumman for the optical technology

and optical system design. The new

telescope is the scientific successor to

NASA’s Hubble Space Telescope and will

be the most powerful space telescope

ever built. Webb is targeted to launch

from French Guiana aboard an Ariane 5

rocket in 2018.

nasa.gov.Inside a massive clean room at NASA’s Goddard Space Flight Center, a robotic am is used to

install the 18th mirror segment onto the Webb telescope structure. Courtesy of NASA/

Chris Gunn.

When Materials Performance is Critical… TRUST Instron Instron ® provides automotive engineers with the tools needed to gain insights around material processability and component performance. 825 University Avenue, Norwood, MA 02062 | 1.800.564.8378 | go.instron.com