A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A R C H

2 0 1 6

7

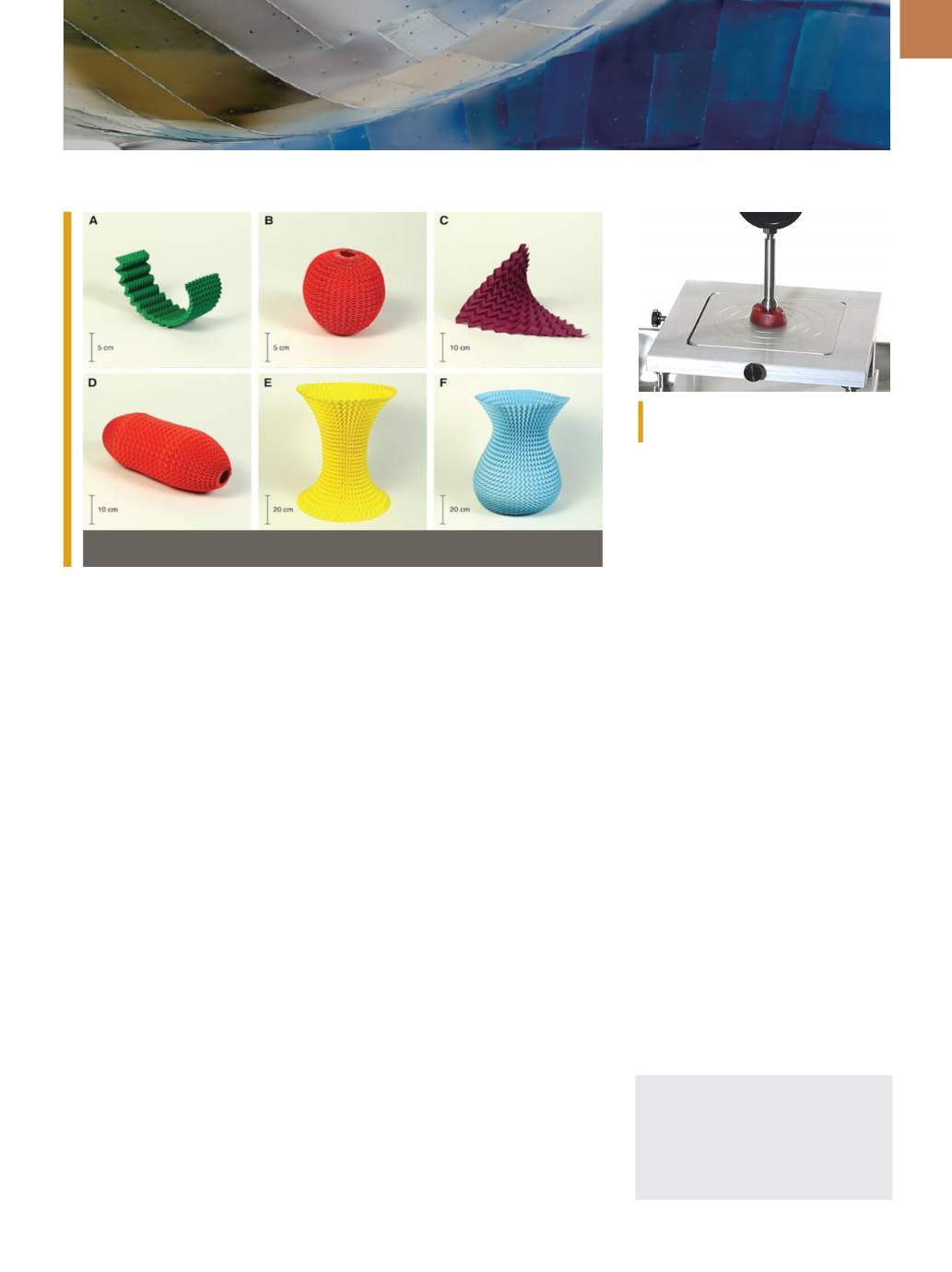

ORIGAMI FOLD CREATES

COLLAPSIBLE STRUCTURES

A team of researchers at Harvard

University, Cambridge, Mass., have

characterized a fundamental origami

fold, or tessellation, that could be used

as a building block to create almost

any 3D shape, from nanostructures to

buildings. The folding pattern, known

as the Miura-ori, is a periodic way to

tile the plane using the simplest moun-

tain-valley fold in origami. A folded Mi-

ura can be packed into a flat, compact

shape and unfolded in one continuous

motion. “The collapsibility, transport-

ability, and deployability of Miura-ori

folded objects makes it a potentially

attractive design for everything from

space-bound payloads to laparoscop-

ic surgery,” says graduate student Levi

Dudte.

To explore the tessellation’s po-

tential, the team developed an algo-

rithm that can create certain shapes

using the Miura-ori fold repeated with

small variations. Given the specifica-

tions of the target shape, the program

lays out the folds needed to create the

design, which can then be laser printed

for folding.

harvard.edu.

Are you working with or have you

discovered a material or its properties

that exhibit OMG - Outrageous

Materials Goodness?

Send your submissions to

Julie Lucko at

julie.lucko@asminternational.org.OMG!

OUTRAGEOUS MATERIALS GOODNESS

Shapes made from the Miura-ori pattern. Courtesy of Mahadevan Lab.

The TA1 analyzes the texture of foods,

including confectionary items.

FOOD TESTING MACHINE

OFFERS TEXTURE ANALYSIS

Ametek Sensors, Test & Calibra-

tion, Largo, Fla., developed a machine

that quantitatively analyzes the texture

of foods. The Lloyd Instruments TA1 per-

forms detailed texture profile analysis

(TPA), a process used in the confection-

ary industry to measure food attributes

such as snack bar crispiness, marshmal-

low springiness, caramel chewiness, and

chocolate bar break strength.

The TA1 has a 102 kgf capacity, and

its force measurement is accurate to

±

0.5%. Special components are avail-

able, such as knife attachments to test

butter and cream consistencies and flat

ended probes to measure the stickiness

of icings and confectionary fillings. The

snap strength of crackers, tortillas, and

fries can be checked with a modified

three-point bend test. Using special-

ized software, the TA1 can reference a

library of international manufacturing

standards or incorporate video capture

and playback. Once TPA profiles are de-

fined with final testing against human

panels, the procedure can be transferred

to the production line for standard test-

ing during quality control. Using results

from TPA, confectionary manufacturers

are able to adjust ingredient ratios, as-

sess baking and production variables,

and determine shelf life.

ametektest.com.

INTERACTIVE HISTORY

OF METAL

Bodycote, UK, launched an “Inter-

active History of Metallurgy,” a timeline

of 10,000 years of metal processing,

heat treatment, and surface technol-

ogy. Containing over 200 high quality

images and numerous videos, the in-

teractive infographic pays homage to

metallurgy’s Neolithic artisans as well

as the scientific innovators of the 20th

century and a multitude in between.

Starting in 8700 B.C. with the world’s

oldest known copper artifacts, the col-

or-coded timeline lets users follow the

story of that metal over time. Pathways

for bronze, iron, and steel are added as

they come into play through the ages.

The resource was developed to explore

the evolution of metallurgy and heat

treating and to acknowledge the col-

lective work of scientists and engineers

who have enhanced the properties of

metals and alloys throughout human

history.

bodycote.com/history-of-metal.