A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A R C H

2 0 1 6

1 7

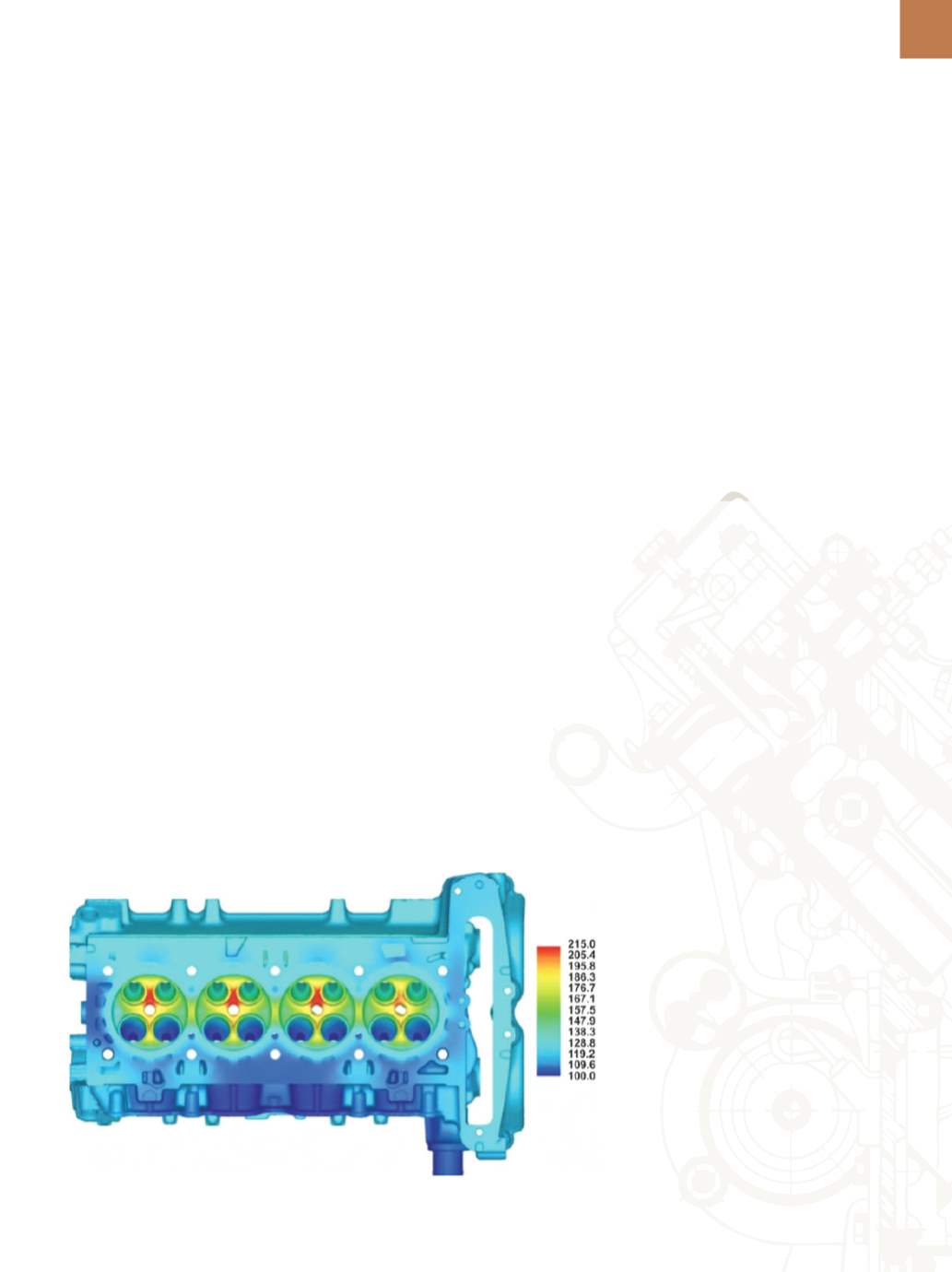

Fig. 1 —

Modeled temperature distribution within a combustion engine

[2]

.

T

he use of aluminum alloys in au-

tomotive applications continues

to grow because they offer an

economically viable way to improve

vehicle performance and efficiency, en-

suring safety and durability, enhancing

fuel consumption, and reducing harm-

ful emissions. The U.S. Environmental

Protection Agency and U.S. Depart-

ment of Transportation issued 2017-

2025 corporate average fuel economy

(CAFE) targets for both passenger cars

and light trucks calling for more than

50% improvement compared with cur-

rent targets. Substantial improvements

in fuel economy can be achieved by

increasing engine performance and by

replacing large engines with smaller

ones in the same vehicle class. Smaller

engines require lighter support, which

means additional weight reduction.

Computer simulations of a diesel en-

gine show that a 60% increase in power

and torque requires an increase in max-

imum cylinder-head pressure of 180 to

300 bar, an increase in peak tempera-

ture on the head combustion face of

215

°

to 275

°

C, and of 150

°

to 190

°

C on

the water-jacket face

[1]

. These goals re-

quire significant technological changes

in engine materials.

Cast aluminum alloys are attrac-

tive structural materials for a number

of automotive applications including

strategic

powertrain

components,

such as engine blocks and cylinder

heads, where permanent-mold cast-

ing and high-pressure die casting are

cost-effective mass production meth-

ods (Fig. 1). The most versatile casting

aluminum alloys are Al-Si alloys, ac-

counting for the majority of automotive

cast parts. The maximum operating

temperature of 180

°

C for existing Al-Si

casting grades (Al-Si-Cu and Al-Si-Mg) is

too low for new combustion-engine de-

signs, where an improvement in perfor-

mance requires both increasing service

temperature and internal pressure. This

article describes research aimed at de-

veloping cast aluminum alloys with the

necessary high-temperature tensile and

fatigue strengths to withstand the mod-

ern automotive engine environment.

INCREASING THERMAL

STABILITY

The strengthening mechanism

of current Al alloy grades becomes in-

effective at the service temperature

of new engine designs due to rapid

coarsening and dissolution of their mi-

crostructure controlling phases. This

requires modifying the base composi-

tion of aluminum alloys. Elements in-

vestigated for this purpose include Ni,

Fe, Cr, Mn, Co, Zr, Gd, Hf, Y, Sc, Nb, and

V. When alloyed with Al, some elements

form incoherent dispersoids, such as in

the Al-Fe-Ce, Al-Fe-V-Si, Al-Fe-Ce-W, and

Al-Cr-Zr-Mn systems. Alloying Al with Sc

forms coherent dispersoids, where their

low fraction is effective in preserving

high-temperature properties. Strength-

ening is also induced through incoher-

ent oxide particles such as in Al-Mg and

Al-Ti systems, but resulting alloys have

low ductility and fracture toughness.

For effective improvement of the high

temperature performance of Al, alloy-

ing elements should

[3]

:

•

Be capable of forming thermally

stable strengthening phases

•

Have low solid solubility in the Al

matrix

•

Have low diffusivity in the Al matrix

•

Retain the ability for the alloy to be

conventionally solidified

Transition metals, which form

thermally stable and coarsening-

resistant precipitates, arepromising can-

didates to achieve this. Phase diagrams

and crystallographic data indicate that

some transitionmetals crystallizewith Al

to form stable Al

3

M-trialuminides. Trialu-

minide intermetallic compounds (Al

3

X)

are good candidates for dispersoids

and precipitates in high-temperature

aluminum alloys. High symmetry cubic

L1

2

and related tetragonal D0

22

and D0

23

structures are prevalent among some

transition metals. This work focuses on

Zr, V, and Ti combined with the Al-Si-Mg-

Cu cast matrix

[4-7]

.

The best results were generat-

ed for simultaneous micro-additions

(0.1-0.5 wt%) of Zr, V, and Ti to the hy-

poeutectic Al-7Si-1Cu-0.5Mg (wt%)

base. The alloy’s chemical composition

is listed in Table 1.

ALLOYING IMPACT ON

MICROSTRUCTURE

Al-Si-Cu-Mg base alloys have a

complex microstructure consisting of

a number of phases including den-

dritic

α

-Al, modified eutectic silicon,

blocky-type copper base

θ

-Al

2

Cu phase,

ternary eutectic Al-Al

2

Cu-Si phase,

Mg-rich Chinese script-like Q-phase

Al

5

Cu

2

Mg

8

Si

6

, and Fe-rich needlelike

π-phase Al

8

FeMg

3

Si

6

[8]

. Additions of tran-

sition metals make this microstructure

muchmore complex (Fig. 2a). For exam-

ple, the presence of Ti leads to an addi-

tional needlelike phase (AlSi)

3

Ti, while

additions of Ti and Zr form needlelike

phase (AlSi)

3

(TiZr). The simultane-

ous presence of Zr-Ti-V leads to new

unique (AlSi)

x

(TiVZr)-type phases with

D0

22

/D0

23

tetragonal crystal structure and