A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A R C H

2 0 1 6

1 9

durability of materials for use in power-

train applications. Creep deformation is

slow, continuous, and time dependent.

In contrast to elastic/plastic deforma-

tion where strain is mainly a function of

stress and temperature, creep strain is a

function of time as well. In-situ neutron

diffraction was used for an in-depth

analysis of creep evolution in the alloys

under elevated temperatures of 200

°

and 250

°

C

[10]

. The focus of this exper-

imental research includes elastic and

plastic tensile creep properties near the

yield strength of the material, typical in

automotive powertrain applications.

associated with power law-governed

creep. The creep mode shifted to the

power-law breakdown as the applied

load was incrementally increased; this

was dominant for most testing condi-

tions. Crystallographic planes (111) and

(311) were typically the main planes

that supported most of the applied

load during testing of both alloys. Acti-

vation of the additional crystallograph-

ic planes, such as (200) and (220) in

the research alloy to support the load

at the higher load settings and at the

higher temperature of 250

°

C was due to

accumulation of dislocations through

the loading stages and by thermal

activation.

FATIGUE BEHAVIOR

The failure mechanism in automo-

tive powertrain components subjected

to high pressure, changing high loads,

and thermal gradient is often fatigue

related. Load cycling between low and

high stress leads to a shorter lifetime

than a static load at high stress. Fatigue

is of special importance for cast alloys

due to a variety of casting defects,

which serve as sources of crack initia-

tion. Combined analysis of creep and

fatigue provides valuable input into

the alloy performance. The response of

cyclic stress amplitude as a function of

the number of cycles at different strain

amplitudes was measured for the re-

search alloy. Fatigue life decreased

and stress amplitude increased with

increasing strain amplitude for the T6

temper condition. At lower total strain

amplitudes in the range of 0.1-0.2%, cy-

clic stress amplitude remained essen-

tially constant throughout the entire

fatigue life. At higher total strain am-

plitudes in the range of 0.4-0.6%, cyclic

hardening occurred from the beginning

and continued to failure for the T6 tem-

pered samples as cyclic deformation

progressed

[11]

.

Fatigue lifetime S-N curves for

both alloys in the T6 tempered condi-

tion are shown in Fig. 4

[6]

. Fatigue life in-

creasedwith decreasing total strain am-

plitudes for all alloys, and fatigue life of

the research alloy is significantly longer

at all levels of total strain amplitudes.

According to the testing regime, if alloy

Test data enabled defining creep mech-

anisms characteristic for each stage of

incremental loading. The research alloy

exhibited considerable improvement in

creep resistance over that of A380 grade

at 200

°

and 250

°

C in terms of ultimate

strength and total (plastic and elastic)

creep. The improvement was explained

by profiles of elasticmicrostrains, which

indicate that additional crystallograph-

ic planes were activated in supporting

the applied load.

Test results showed that the

main mechanism is dislocation creep,

which initiates at the lower load setting

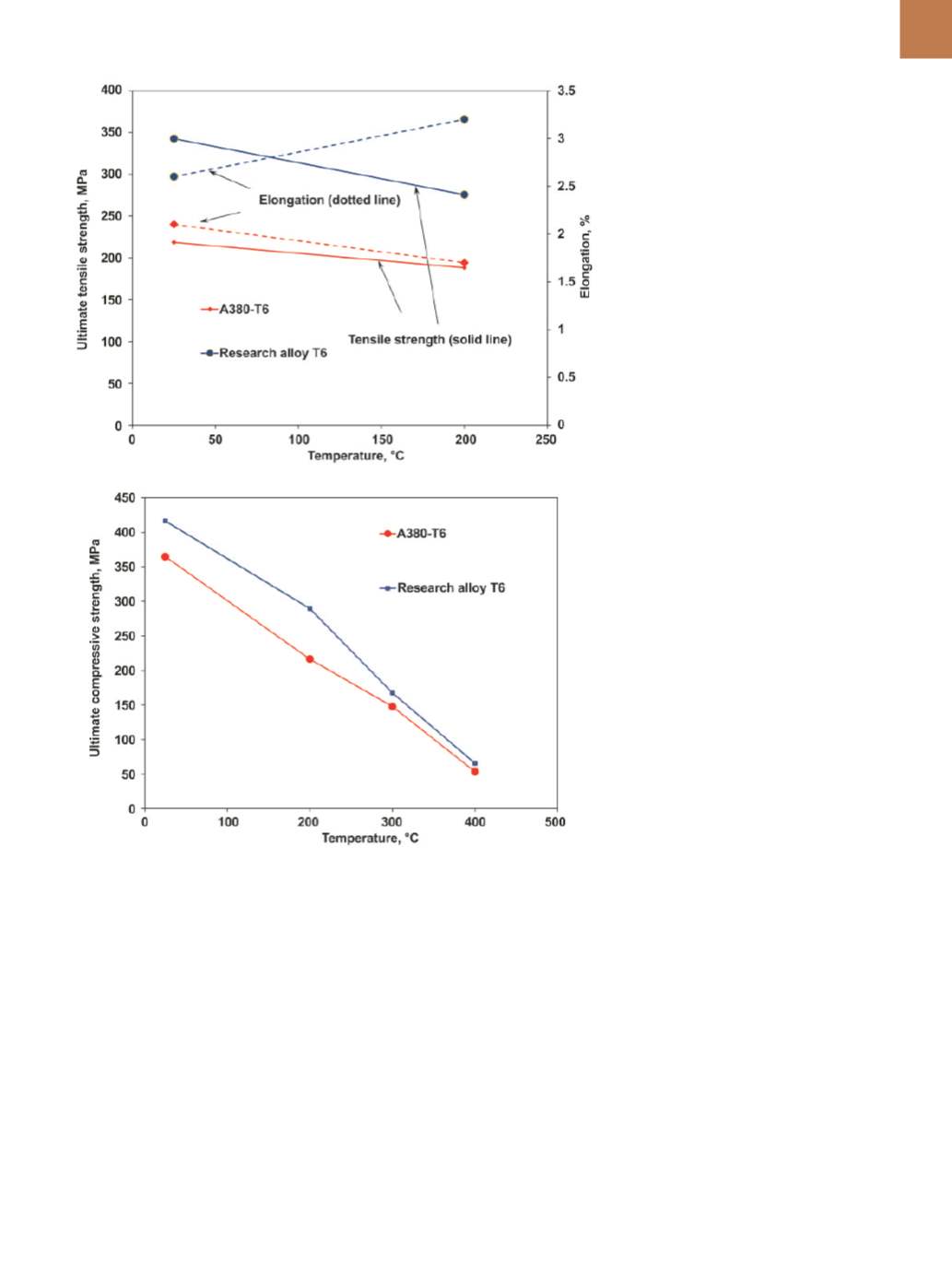

Fig. 3 —

(a) Ultimate tensile strength and (b) compressive strength of research and A380 alloys

after T6 heat treatment tested at room and elevated temperatures.

(a)

(b)