A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A R C H

2 0 1 6

2 7

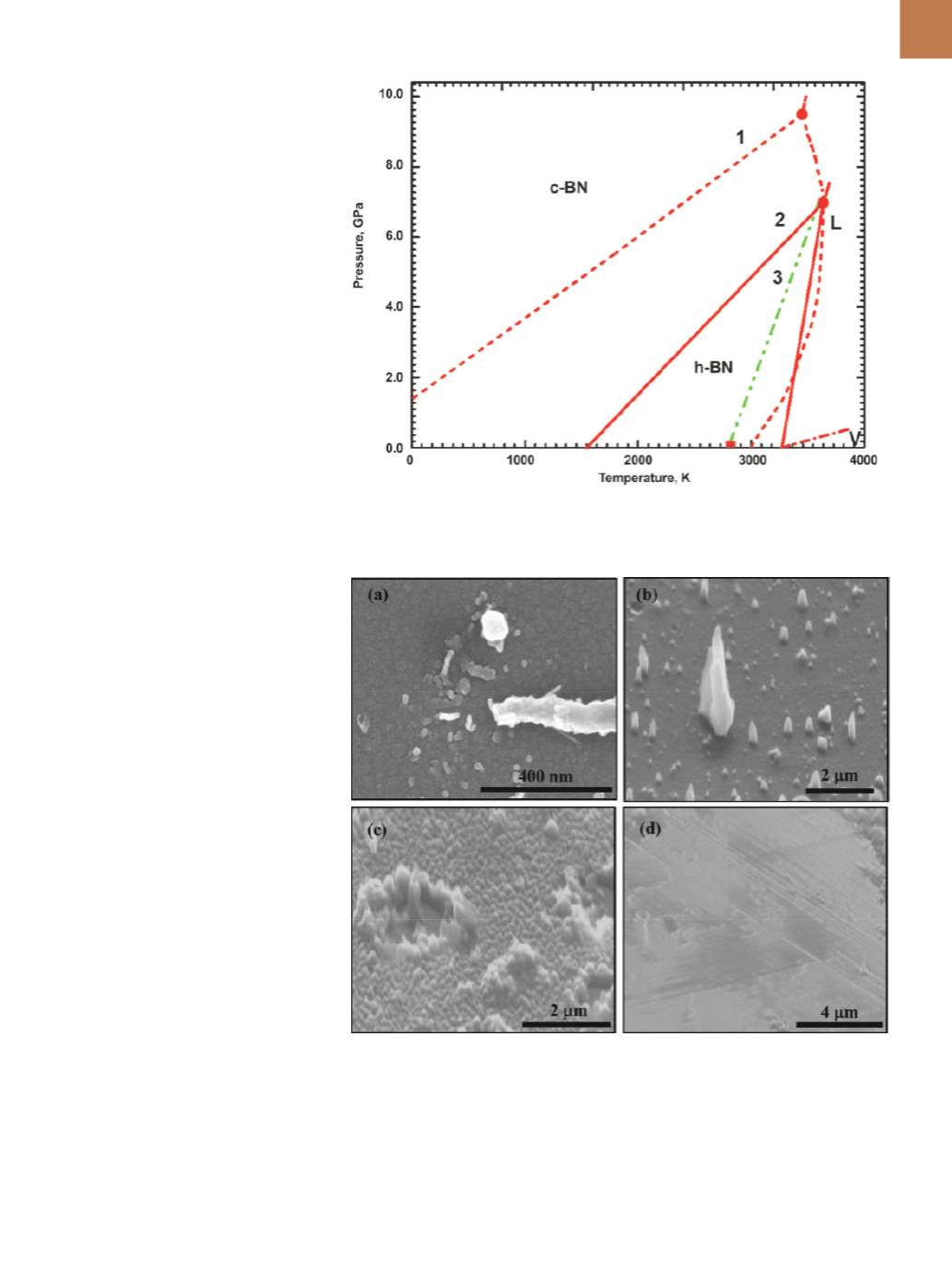

According to the phase diagram, the

transformation from h-BN into c-BN can

occur only at high temperatures and

pressures, as the hBN-cBN-liquid triple

point is at 3500K/9.5 GPa. Nanosecond

laser melting creates a super-under-

cooled state and shifts the triple point

to as low as 2800K and atmospheric

pressure. Rapid quenching from the su-

per-undercooled state leads to forma-

tion of Q-BN. The c-BN phase is nucle-

ated from Q-BN depending on the time

allowed for nucleation and growth.

Figure 4 shows the BN phase dia-

gram in the pressure and temperature

range of 0-10 GPa and 0-4000K, re-

spectively, containing regions of phase

stability for c-BN, h-BN, liquid, and va-

por

[11]

. According to the phase diagram

of Corrigan and Bundy (curve 1), the

c-BN line intersects the pressure axis at

1.4 GPa at 0K without crossing the tem-

perature axis, making h-BN the stable

phase in the entire temperature range

of 0 to 3000K, above which BN turns

into vapor

[11]

. Solozhenko, et al., tried

to refine the phase diagram based on

experimental data on BN melting and

extrapolation of specific heats of vari-

ous BN polymorphs into high-tempera-

ture regions. This modification (curve 2)

shifts the L-cBN-hBN triple point from

3500K/9.5 GPa (Corrigan-Bundy P-T dia-

gram) to 3700K/7.0 GPa, and shows cBN

is the stable phase in the temperature

range of 0 to1600K, and h-BN beyond

that at atmospheric pressure

[12-13]

.

Figure 5a shows the formation of

Q-BN and nano and microcrystallites of

c-BN after treatment with a single laser

pulse. Figure 5b shows the formation

of single-crystal nanoneedles and mi-

croneedles of c-BN; some microneedles

are over two microns long. The mech-

anism of nanoneedle and micronee-

dle formation is illustrated in Fig. 5c,

where interfacial instability in super-

undercooled BN leads to the forma-

tion of periodic features on the order of

90 nm, which coalesce to form larger

size microneedles.

Large-area single crystal thin films

are formed in the middle of the laser

beam, where there is 100% conversion

of h-BN into phase pure c-BN (Fig. 5d).

Thus, c-BN structures in the form of

nanodots, nanorods, microcrystalline

thin films, and large-area single crystal

c-BN thin films are formedby controlling

laser parameters. These structures are

phase-pure c-BN with 100% conversion

from h-BN into c-BN

[14]

. CVD methods

for c-BN processing are not well estab-

lished, and only 85% phase-pure c-BN

Fig. 4 —

BN phase diagram showing P-T phase space for stability of h-BN, c-BN, and liquid BN

(L): Dotted lines based on Bundy

[11]

, dotted lines are recent modifications

[12-13]

, and dash-dot line

extension for super-undercooling

[11]

.

Fig. 5 —

SEMmicrographs: (a) nucleation of c-BN fromQ-BN (mechanism of h-BN to c-BN

conversion), (b) formation of c-BN nanoneedles andmicroneedles up to three microns long,

(c) mechanism of initial stages of formation of nanostructures consisting of their coalescence

and nanoneedle evolution, and (d) formation of large area flat c-BN films.