A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A R C H 2 0 1 6

3 0

METALLURGY LANE

Metallurgy Lane, authored by ASM life member Charles R. Simcoe, is a continuing series dedicated to the early history of the U.S.

metals and materials industries along with key milestones and developments.

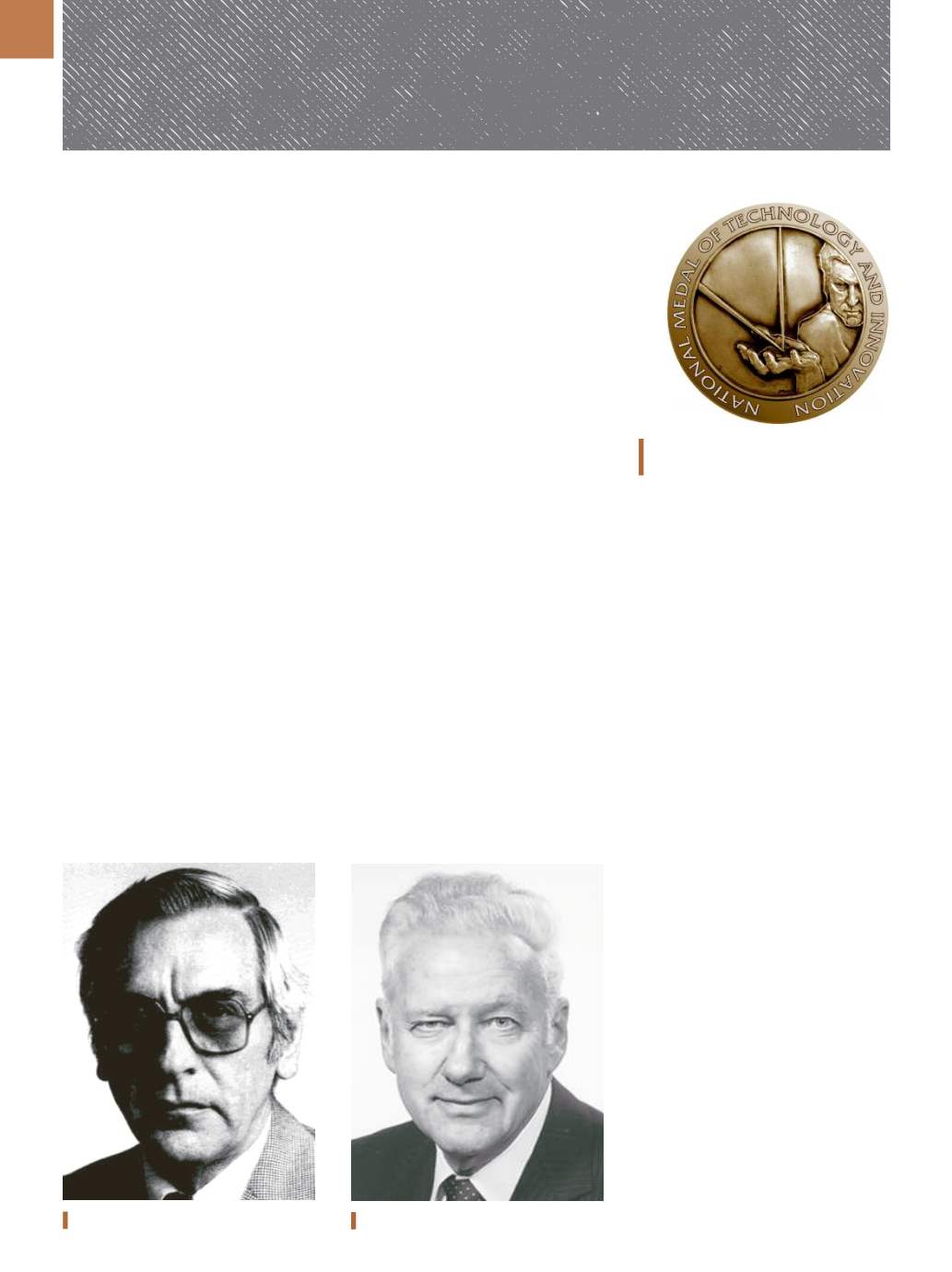

PIONEERS IN METALS RESEARCH—PART VI

THE INVENTION OF THE SINGLE CRYSTAL JET ENGINE BLADE UNDER FRANK

VERSNYDER AND A TEAM OF SCIENTISTS AT THE PRATT &WHITNEY DIVISION OF

UNITED TECHNOLOGIES IS CONSIDERED ONE OF THE 50 GREATEST ADVANCES IN

METALLURGICAL HISTORY.

T

he research program involving

single crystal jet engine blades be-

gan in the early 1960s at the Pratt

& Whitney Division of United Technolo-

gies Corp. It was spearheaded by Francis

Louis VerSnyder who had just joined the

company. During this era, Pratt & Whit-

ney was expanding its research efforts

into making major improvements in the

metal alloys used in the hottest part of

the jet engine. This initiative was a long-

range project with a goal of eliminating

failures that sometimes occurred at the

grain boundaries of cast turbine blades.

These blades were made of nickel base

alloys that could withstand the extreme

operating temperatures.

VerSnyder grew up in Watertown,

N.Y., as an only child in a single par-

ent household. His mother died at his

birth, and his father was old enough to

be his grandfather. In the 1940 census,

VerSnyder was listed as 14 years old

and his father as 56. He attended local

parochial schools through high school

and joined the army in 1943 at age 18.

He served in the 54th Armored Infantry

Division in Italy, France, and Germany.

He was wounded several times and re-

ceived the Purple Heart with Oak Leaf

Cluster and campaign ribbons with four

battle stars. He was discharged in fall

1945, still just 20 years old.

VerSnyder attended Notre Dame

University on the GI Bill, earning a B.S.

in Metallurgical Engineering in 1950. He

then joined the Small Aircraft Engine

Division of General Electric Co. in Lynn,

Mass. By 1955, he had transferred to the

Central Research Laboratories of GE in

Schenectady, N.Y., where he remained

until 1961 when he was recruited by

Maurice Shank from the Pratt & Whitney

Engine Division of United Technologies

Francis Louis VerSnyder.

Corp. At P&W, he supervised a newgroup

that had a 10-year goal of improving the

reliability of engine blades operating in

the hottest part of the engine.

GRAIN BOUNDARIES

IN CASTINGS

When molten metal is cast into a

ceramic mold, solidification begins at

the cold wall of the mold. The solid met-

al grows as crystals into the remaining

liquid until it fills the complete space of

the mold. Each of these growing crys-

tals—or grains—contacts other grains

that are growing at different orientations

in space. Where they meet, they form

boundaries that must adjust to these

different orientations. These boundaries

are weak regions in the alloy.

Cast turbine blades have many

grains that can be seen by chemically

etching the surface. Some areas of the

boundaries lay along the length of the

blade while others lay across it, called

transverse boundaries. In operation,

blades spin at very high revolutions

per minute so the major stress is along

the blade’s length. The boundaries that

cross the blades are the ones that are

weak during operation, and failure can

occur by separation at these boundaries.

DIRECTIONALLY SOLIDIFIED

ENGINE BLADES

The original goal of the pro-

gram was to grow grains in only one

Maurice “Bud” Shank.

VerSnyder received the National Medal of

Technology and Innovation in 1986.