A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A R C H 2 0 1 6

2 6

quenched into a new state of Q-carbon

from which nanodiamonds, microdia-

monds, and microneedles are formed.

The structures obtained from practical,

inexpensive sapphire and glass sub-

strates are conveniently harvested and

substrates recycled, thus reducing the

carbon footprint and creating very use-

ful products for mankind.

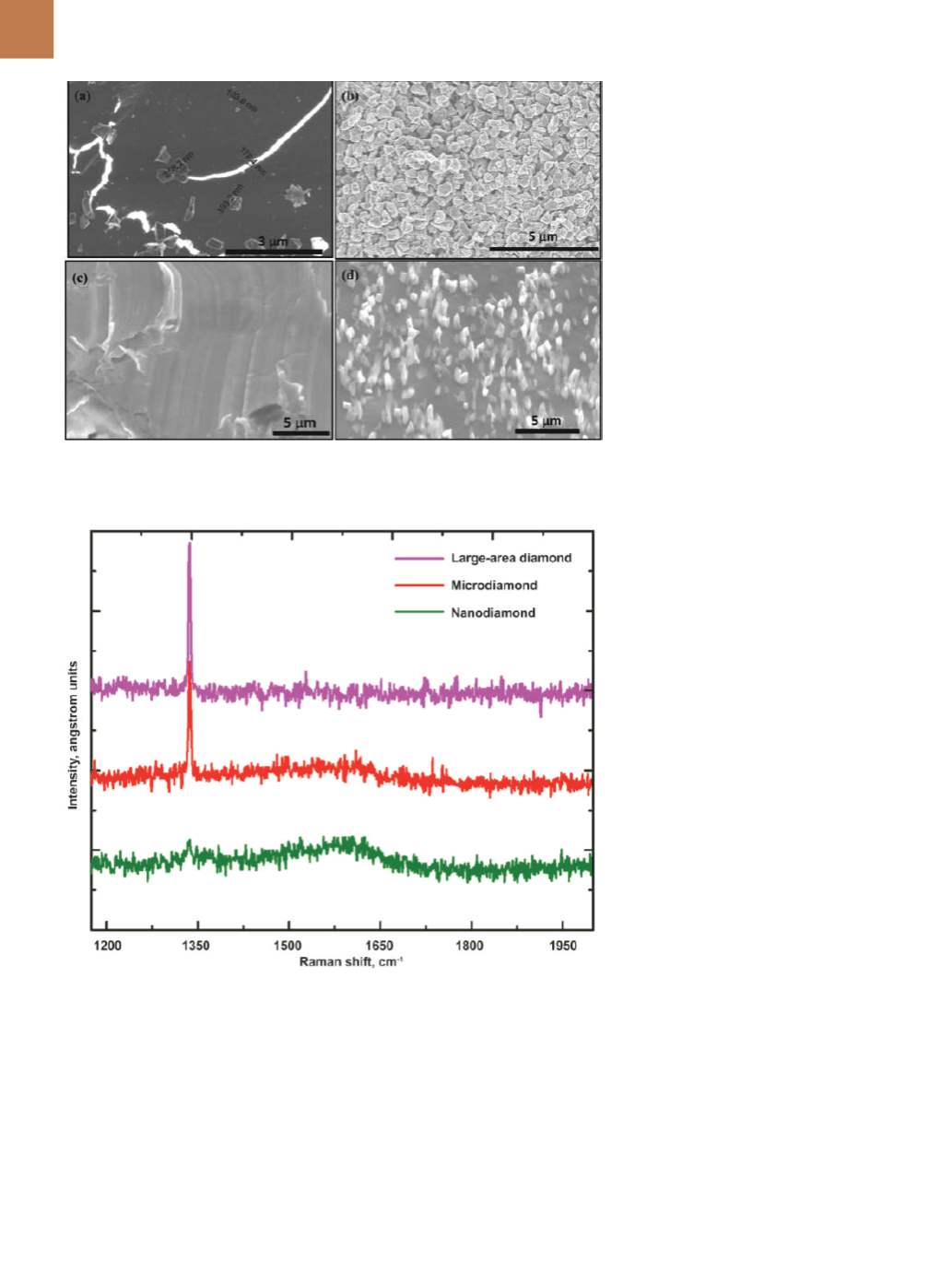

Q-carbon serves as a mother

source for diamond nucleation and

growth. Figure 2a shows the formation

of Q-carbon and growth of microdia-

mond from it after irradiation with a

single laser pulse. The Q-carbon exhib-

its a bright contrast under secondary

electron imaging in a scanning elec-

tron microscope. Kelvin probe force

microscopy (KPFM) was used to mea-

sure surface potential on the Q-carbon

filaments, which were embedded into

diamond-like carbon. Results show up

to 40 meV lower surface potential than

that of diamond-like carbon, indicat-

ing a higher field-emission potential

compared with the already inherently

high field-emission properties of dia-

mond-like carbon. Surface potential

decreases at nanodiamonds embedded

into the Q-carbon filaments, and is low-

er than Q-carbon values.

Measurements are consistent with

secondary electron-emission contrast

in the SEM images, showing significant-

ly enhanced contrast for the Q-carbon.

Controlling diamond nucleation and

growth enables converting all the car-

bon into microdiamonds (500 nm aver-

age size) as shown in Fig. 2b. Formation

of large-area single-crystal diamond

films is achieved when sapphire is pro-

vided as a template during growth from

the super-undercooled state as shown

in Fig. 2c. Formation of 200 to 300-nm

diameter by up to 3.0 µm long nanon-

eedles and microneedles is achieved

by nucleation and growth of diamond

from liquid carbon. The micronee-

dles are single crystals, and grow out

of Q-carbon near the film-substrate

interface.

Raman spectroscopy is used to

characterize diamond and related ma-

terials

[10]

. Its versatility is further im-

proved by using a range of excitation

wavelengths, particularly one wave-

length in the UV range, as the sensi-

tivity to sp

3

bonding is the strongest.

Figure 3 shows spectra from nanodia-

mond, microdiamond, and large-area

thin films. The characteristic sharp

peak at 1332 cm

-1

confirms the forma-

tion of diamond phase and the poten-

tial of the transformative technique.

The results in Fig. 3 are from 8-nm

nanodiamond, 500-nm microdiamond,

and 50+

µ

m thin film.

DIRECT CONVERSION OF

HEXAGONAL AND CUBIC BN

Direct conversion of h-BN into

pure c-BN is accomplished by nanosec-

ond laser melting at ambient tempera-

tures and atmospheric pressure in air.

Fig. 2 —

SEMmicrographs: (a) nucleation of microdiamond from the Q-carbon (mechanism of

carbon into diamond conversion), (b) mixture of nanodiamond andmicrodiamond, (c) entire

area covered with microdiamond, and (d) diamond nanoneedles andmicroneedles.

Fig. 3 —

Raman spectroscopy of nanodiamond, microdiamond, and large-area thin films using

633 nm laser excitation wavelength.