A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A R C H

2 0 1 5

2 5

long-term creep testing of weldments

to confirm improved heat-affected zone

(HAZ) creep strength, while forging and

tubing production for in-plant testing

and cast MARBN steel and subsequent

testing are also being developed.

Overall, efforts were impressively

coordinated among the various par-

ties involved, including partners from

academia, research institutions, manu-

facturers, and utilities. From the stand-

point of steam power plant technology,

Europeans were the first to develop

and demonstrate materials for a 700°C

power plant, with U.S. and Japanese

programs developing materials for tem-

peratures up to 760°C later. EU efforts

in both >750°C steam operation and

incremental improvements to steels

for operation at 650°C, presented at the

conference, demonstrate broad global

competitiveness in this technology area.

CREEP-FATIGUE

One key development discussed

extensively is the need for flexible op-

eration of conventional power plants.

This recent flexibility requirement is

largely due to the mandate to supply a

larger fraction of power from renewable

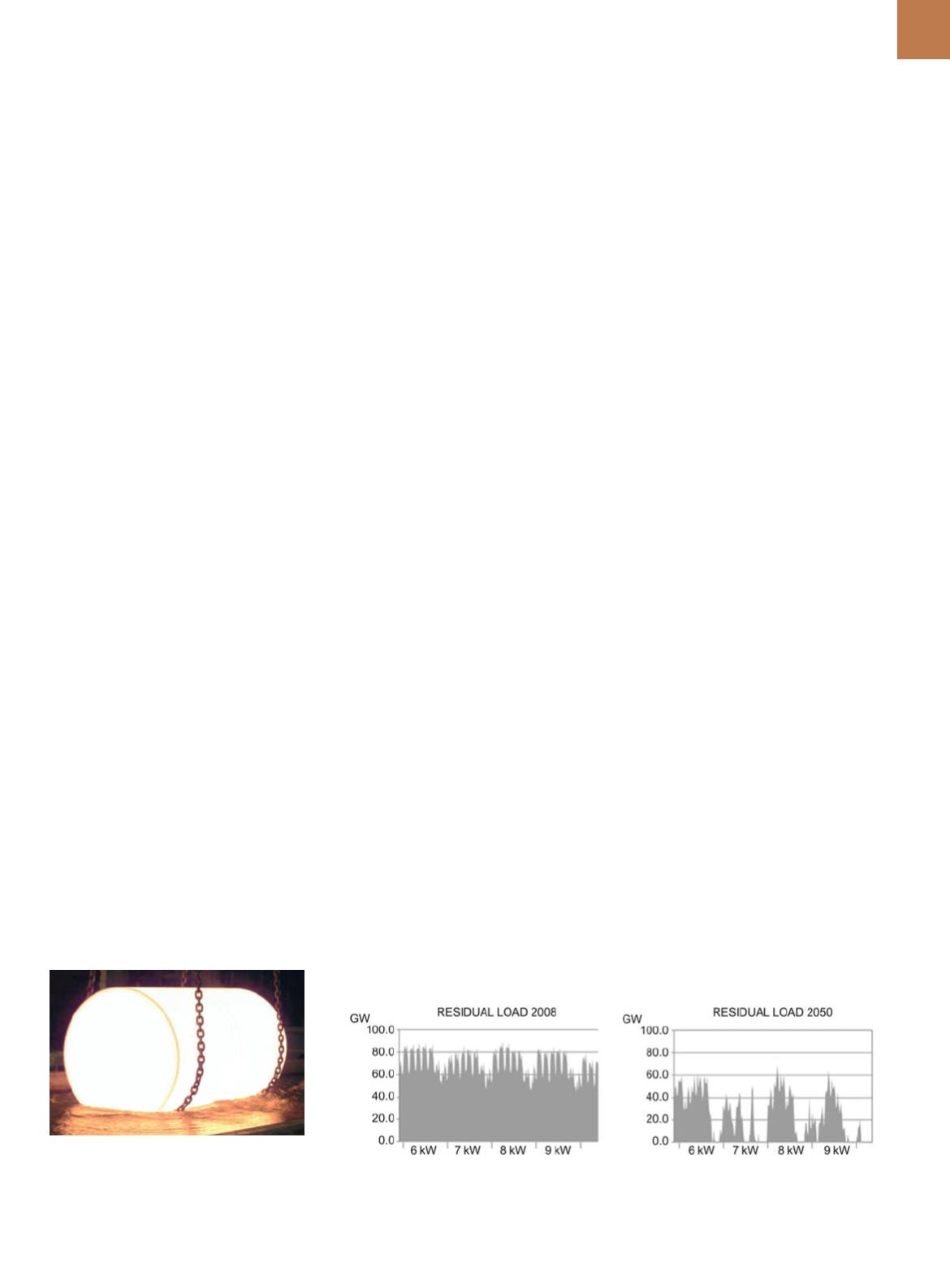

sources. For example, the total pow-

er generated from renewable sources

in Germany increased threefold over

the past 10 years, and is expected to

continue. The residual load character-

istic (difference between total electric

energy consumption and supply by

renewable sources) of a time period in

2008 compared to the same projected

time period in 2050 is shown in Fig. 2.

The loading spectrum of power plants

will change dramatically in the coming

years, a process that has already begun.

The changing operation mode of

conventional power plants has created

the need for improved tools that can

predict creep-fatigue damage interac-

tion in materials. Organizations such

as the Electric Power Research Institute

(U.S.) and VGB (Germany) have formed

working groups to standardize testing,

analysis, and design procedures associ-

ated with creep-fatigue damage. A sim-

ple example illustrating these changing

requirements is one associated with

thick-walled components—going to

thicker sections to alleviate creep dam-

age can have a negative influence on

the component’s thermal fatigue life-

time. At least two analysis procedures

to quantify creep-fatigue damage were

presented at the conference, one in-

volving creep-fatigue damage summa-

tion diagrams and the other focused on

fracture-mechanics-based cyclic crack

tip opening displacement parameters.

Creep-fatigue damage assessment

tools must be developed in parallel

with higher performance materials with

improved creep-fatigue resistance. For

power plant steels, creep-fatigue dam-

age development is reported to be in-

fluenced by the temperature and strain

range, strain rate, hold time, creep

strength, and creep ductility of the ma-

terial. The traditional understanding of

creep-fatigue interactions is based on

studies of low alloy ferritic and austen-

itic steels. However, this understanding

may not translate well to new advanced

materials with significantly different

deformation and oxidation responses.

For example, for 9% to 11% Cr

steels at temperatures above 525°C, the

dominant source of damage accumula-

tion comes from fatigue-oxidation rather

turbine rotors, and steam turbine cas-

ing, with a focus on nickel-base alloy

263. The project is coordinated by DNV-

GL, with Doosan Babcock leading the

boiler effort, Skoda Power leading the

steam turbine work, and DNV-GL inte-

grating the practical results with mod-

eling efforts. Major activities include

fireside corrosion testing using boiler

probes; laboratory work to understand

and model fireside corrosion and steam

oxidation; optimization of nickel-base

alloy 263; forging trials up to 1000 mm

in diameter on alloy 263 (Fig. 1); demon-

stration of rotor welding; and casting

development, including development

of a new nickel-base casting (G130 by

Goodwin) for heavy sections.

To improve coordinationof the var-

ious multinational programs funded by

the European Union (EU) with national

government programs, a special Ener-

gy Materials working group (WG2) was

formed as part of the Knowledge-Based

Multifunctional Materials Virtual Insti-

tute in 2012. One goal of this program is

addressing the materials gap between

the current 600°C steel technologies for

fossil power plants and the extensive

research taking place in Europe, the

U.S., and Japan on >700°C materials

technology. The group is currently co-

ordinating efforts for industrial scale

demonstrations using the Japanese

originated MARBN (martensitic micro-

structure with boron and nitrogen con-

trol) steel concept. MARBN steels con-

tain highly controlled levels of boron and

nitrogen, which are reported to increase

high-temperature long-term (>100,000

hours) creep strength of steels up to

650°C while helping retain good weld

strength. These steels are undergoing

Fig. 1 —

Full scale, 1000-mm-diameter alloy

263 rotor forging during solution annealing

and quenching. Courtesy of Saarschmiede,

Germany.

Fig. 2 —

Comparison of the residual load characteristic between 2008 and 2050 (projected),

illustrating the growing need for predictive tools in the creep-fatigue interaction regime and

higher performance materials with better creep-fatigue resistance

[1]

.