A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A R C H 2 0 1 5

2 0

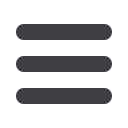

a cast magnesium sail (mirror mount)

part on the front doors. The Fusion

hood is already made of aluminum, so

only a small amount of weight is saved

using the aluminum hinges and latch

housing. The closure-in-white design

(69 kg) reduces 29 kg (30%) from the

2013 Fusion weight. The front door-in-

white, which includes a magnesium

sail casting, an extruded and machined

aluminum hinge pillar reinforcement,

stamped aluminum, stamped steel,

and a boron intrusion beam weighs

10.7 kg, which equals a 35% reduction

(5.9 kg). Figure 2 illustrates the material

distribution for the side doors.

Door designs also include cast

aluminum hinges, tape-on secondary

dynamic seals, and lightweight glaz-

ing. Laminated hybrid glazing reduc-

es the movable glazing from 13.8 kg

(4.3 kg front and 2.6 kg rear) by 4.7 kg

(34%). The door glazing is made up of a

1.8-mm layer of tempered (soda lime)

glass and a 0.8 mm acoustic PVB (poly-

vinyl butyral) layer strengthened with

a 0.7 mm chemically toughened glass

layer (Corning Gorilla Glass). Side door

glazings use a chemically toughened

glass layer located on the exterior

side with tempered glass on the inside

surface.

The fixed glazing includes a lami-

nated hybrid windscreen with a weight

of 9.1 kg—a 36% (5.1 kg) weight savings

from the prior Fusion windscreen with

an additional 4.5-mm-thick polycar-

bonate backlite that weighs just 5.9 kg—a

27% savings. The layered laminate on

the windshield is the same composition

as the side door glazing, but the chemi-

cally toughened glass layer is on the in-

terior. An additional 2.2 kg (15%) reduc-

tion from the functional and black trim,

enabled by using chemically foamed

plastics and 0.4 kg (~20%) in each of

four window regulators, increases the

overall weight savings.

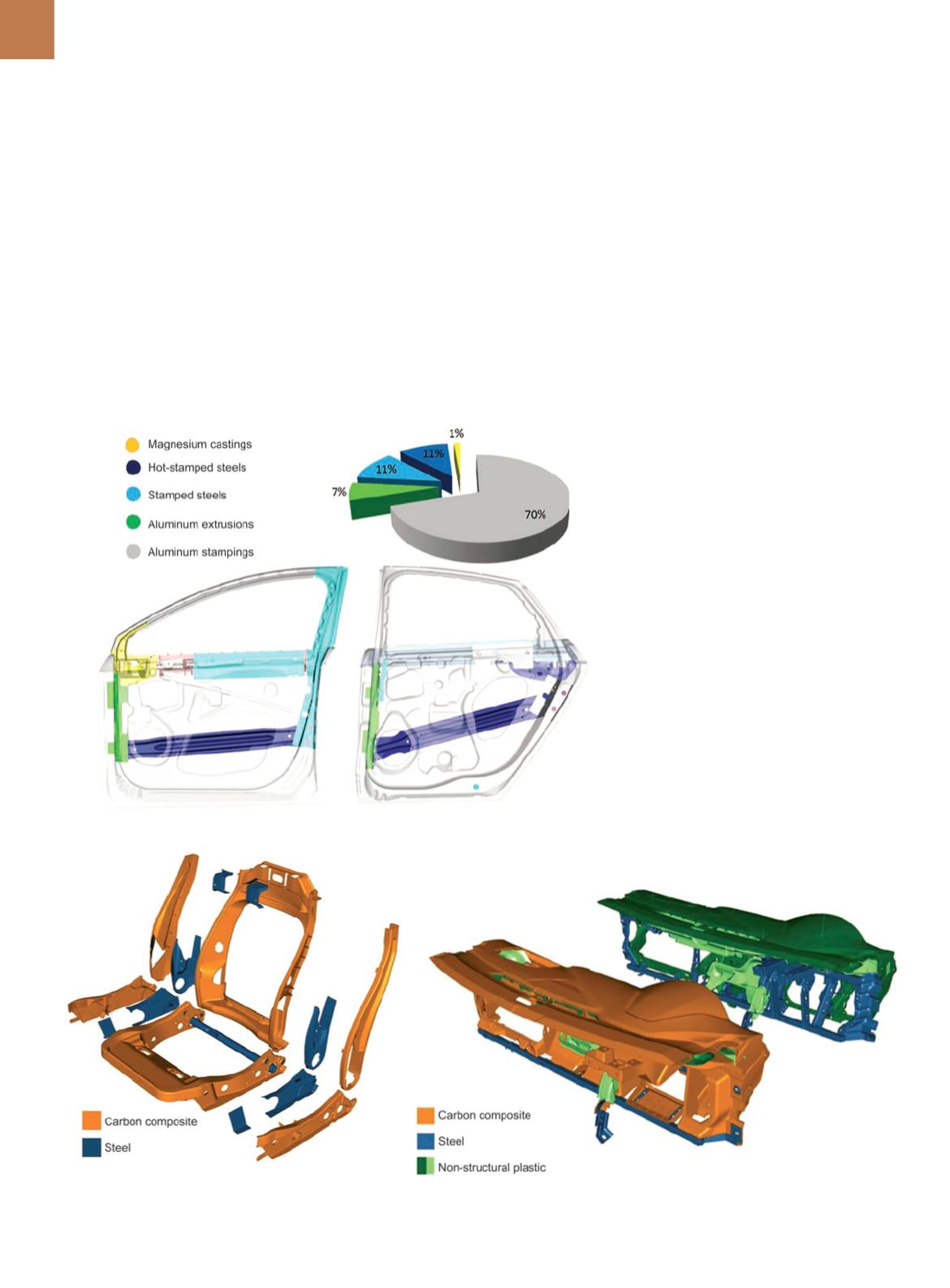

BODY INTERIOR AND

CLIMATE CONTROL

The greatest savings in the body

interior and climate control systems

come from the seats and instrument

panel. Of the 45 kg saved in this system,

36 kg comes from carbon fiber compos-

ite use in structural portions of the seats

and instrument panel. The additional

9 kg of weight savings are made possi-

ble through use of chemically foamed

plastics for interior trim that eliminate

the dual control mode in the HVAC sys-

tem. These chemically foamed plastics

are created using catalysts introduced

during the injection mold process, under

controlled conditions that result in a thin

solid outer skinwith a foamed inner core.

Seat structures made of carbon fi-

ber composite along with reduced foam

and lightweight back panels reduce the

Fig. 2 —

MMLV design door-in-white materials.

Fig. 3 —

Carbon fiber composite seat parts and

material distribution.

Fig. 4 —

Fusion and MMLV design instrument panel beams and HVAC ducts.