A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A R C H

2 0 1 5

2 3

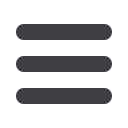

TABLE 2—MMLV WEIGHT REDUCTION ON A VEHICLE SUBSYSTEM BASIS

Vehicle

systems and

subsystems

2013

Ford

Fusion

weight,

kg

MMLV

weight,

kg

MMLV curb

weight, %

MMLV

weight

reduction,

kg

MMLV

weight

reduction,

%

1. Body

525.0

400.4

33.5% –124.6

–23.7%

2. Interior

260.4

202.7

17.0% –57.7

–22.2%

3. Chassis

355.0

260.0

21.8% –95.0

–26.8%

4. Powertrain 337.0

263.1

22.0% –73.9

–21.9%

5. Electrical

57.0

49.5

4.1%

–7.5

–13.1%

A. Assembly

25.0

19.5

1.6%

–5.5

–22.0%

Total vehicle

1559.4 1195.2

100% –364.2

–23.4%

Based on the system definition from the International Organization for Standardization

(ISO) standards.

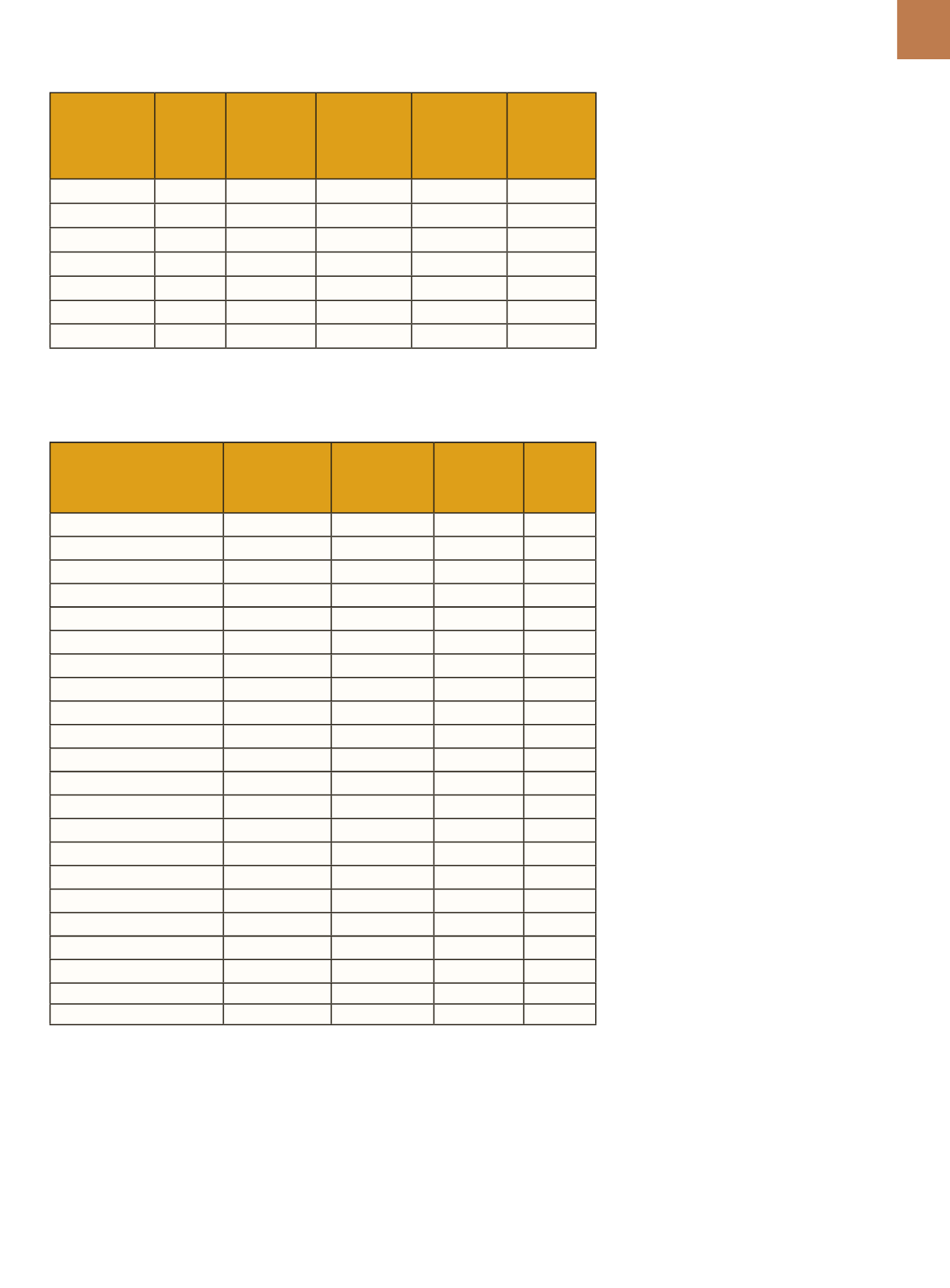

TABLE 3—MAIN MATERIAL COMPOSITION PER VEHICLE ARCHITECTURE

Material

2013 Ford

Fusion

weight, kg

2013 Ford

Fusion

weight, %

MMLV

weight,

kg

MMLV

weight,

%

AHSS

417.5

27%

66.9

6%

Conventional steel

413.7

27%

289.8

24%

Cast iron

50.0

3%

19.6

2%

Forged iron

16.0

1%

10.0

1%

Stainless steel

19.1

1%

9.7

1%

Die-cast aluminum

146.4

9%

147.7

12%

Cold-rolled aluminum 12.8

1%

143.8

12%

Extruded aluminum

15.6

1%

66.9

6%

Forged aluminum

0.0

0%

9.8

1%

Magnesium

2.3

0%

16.0

1%

Copper

33.7

2%

29.3

2%

Titanium

0.0

0%

3.3

0%

CFRP

0.0

0%

54.2

5%

GFRP

0.0

0%

3.4

0%

Plastic

235.4

15%

177.1

15%

Rubber

72.6

5%

52.0

4%

Glass

37.5

2%

26.4

2%

Ceramics

0.8

0%

0.8

0%

Batteries

14.0

1%

8.0

1%

Paint

8.0

1%

7.7

1%

Fluid, adhesive, and other

64.1

4%

52.8

4%

Total vehicle

1559.5

100% 1195.2

100%

design. Completed testing to date in-

cludes a 150-K mile equivalent durabil-

ity test with no major structural issues

in the body, closure, chassis, interior, or

electrical systems. Safety testing for the

new car assessment program (NCAP)

full frontal crash, Insurance Institute

for Highway Safety (IIHS) 40% offset

deformable barrier, side pole impact,

and rear impact testing evaluates the

joining and energy absorption of light-

weight architecture. Safety test results

are complete and under review.

Select NVH (noise, vibration, and

harshness) testing measures the typi-

cally deleterious effects of lightweight-

ing on these vehicle attributes. NVH

data are also under review. Full vehicle

accelerated corrosion tests are under-

way on two MMLV vehicles. Many of

the technologies incorporated into the

MMLV are near term, but not necessar-

ily cost effective. Ford, Magna, and the

automotive industry continue to inves-

tigate innovative ways to incorporate

lightweight materials that are both cost

effective and affordable. Overall, this

concept vehicle is one of the most com-

prehensive studies of a multi-material

lightweight vehicle using technologies

that in the near future will contribute to

lightweight vehicles, better fuel econo-

my, and lower emissions.

~AMP

Acknowledgment

The authors thank their colleagues

in Ford Research & Advanced Engineer-

ing who assisted with the design and

research for the MMLV. Additionally

they thank their Magna partners for de-

sign and engineering efforts. More than

100 research scientists and engineers

contributed to this project. Finally, the

authors thank the U.S. Department of

Energy, Vehicle Technologies Office for

support and ongoing guidance and re-

views. This material is based on work

supported by the DOE National Energy

Technology Laboratory under Award

No. DE-EE0005574.

For more information:

Matthew Zalu-

zec is senior technical advisor, Ford

Motor Co., 2101 Village Rd., Dearborn,

MI 48121-2053, 313.337.1098,

mzaluzec @ford.com, www.ford.com.SUMMARY

The multi-material lightweight ve-

hicle design reduces the weight of a CD

class five-passenger sedan by more than

350 kg—a savings of over 23%. By design-

ingmajor structural systems usingmixed

materials, incorporating aluminum as

well as steel, and using lightweight ma-

terials in all major vehicle systems and

components, the MMLV design sets a

mark for vehicle weight reduction.

Future efforts will build and

test physical prototypes of the MMLV