A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A R C H 2 0 1 5

2 6

than fatigue-creep interactions. Never-

theless, the creep-fatigue resistance of

different material classes scales with

their known response to temperature.

The creep-fatigue crack initiation en-

durance limit for NiCr23Co12Mo (solid

solution strengthened nickel-base al-

loy) at 700°C is similar to that for 9% to

11% Cr steels at 600°C and 1CrMoV steel

at 550°C. The development of materials

with improved elevated temperature

strength may be a first step toward the

development of creep-fatigue-resistant

materials.

NEW MATERIALS

Six invited talks and seven poster

presentations comprised the “new ma-

terials” category, including seven on

bainitic, ferritic-martensitic (F-M), and

ferritic steels, four on austenitic stain-

less steels, and two on Ni-base alloys.

Alloy development trends in the area

of high-temperature structural mate-

rials for power generation systems can

be grouped into three main catego-

ries: Strength improvement of 9-12Cr

F-M steels; higher Cr ferritic steels

strengthened by stable intermetallic

compounds; and newly developed high

Cr-high Ni austenitic stainless steels

with the unique capability of either

high-temperature strength or oxidation

resistance. Most new alloy development

activities focus on Fe-base materials

rather than Ni-base, as cost-effective-

ness is one of the main drivers of mate-

rial down-selection for applications in

power generation systems.

Unique alloy design strategies were

presented that use different types of

second-phase precipitates for strength-

ening: Cr(V,Nb)N-type Z-phase in F-M

steels, Fe

2

W-type Laves phases in high

Cr ferritic steels, and

σ

-FeCr-phase and

Fe

2

Nb-type Laves phases in austenitic

stainless steels. These second-phase

precipitates were recognized as “poi-

sons” for long-termcreep properties due

to their detrimental effects, e.g., promot-

ing decomposition of strengthening na-

noscale carbonitrides and decreasing

toughness and creep ductility due to

their brittle nature. However, research

proves their effective use for improving

creep properties through proper alloy-

ing additions, thermomechanical treat-

ments, and microstructure control.

Computational thermodynamics also

play an important role in the design of

such steel alloys.

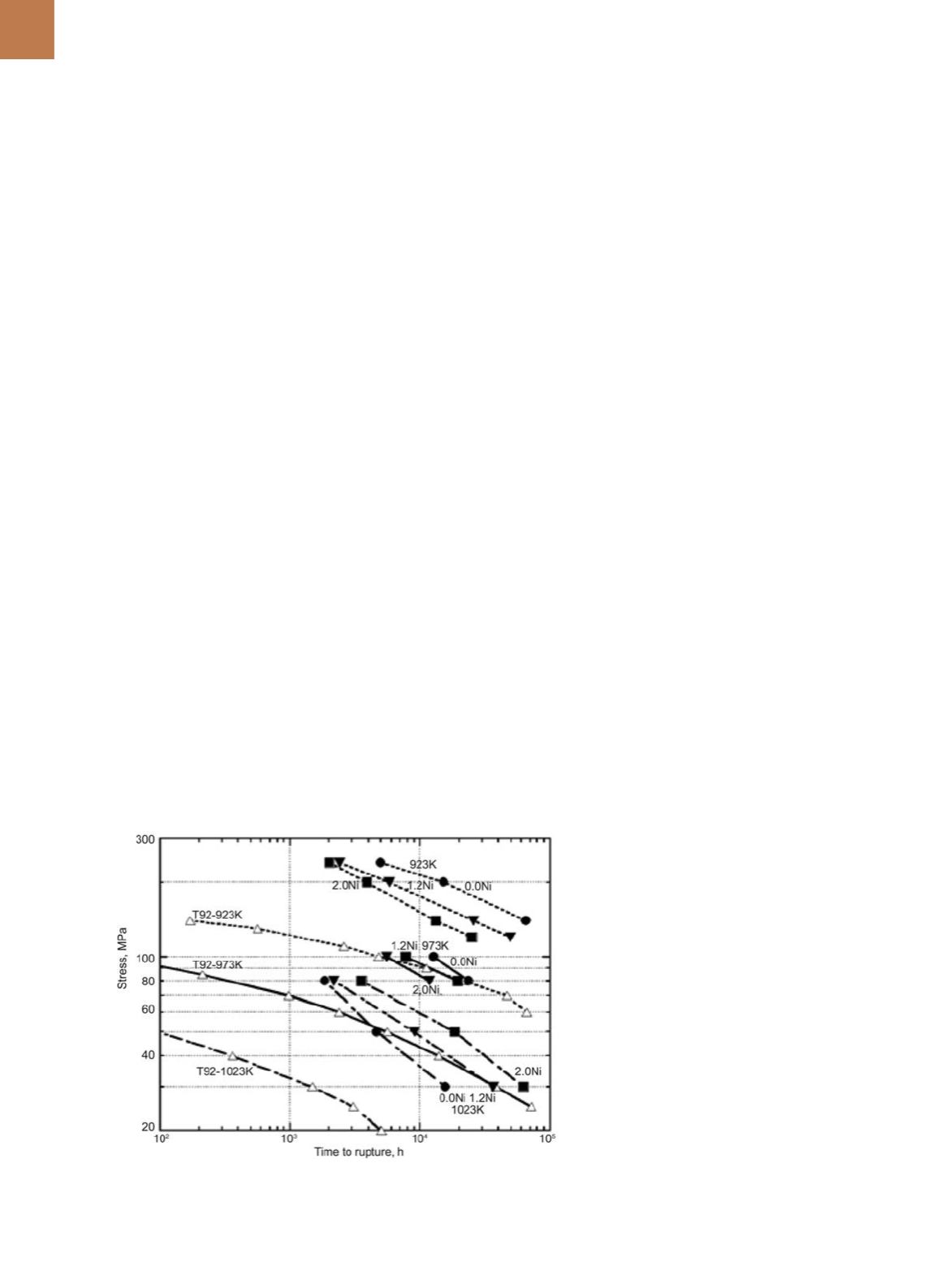

An example of improved creep

properties in high Cr ferritic steels

strengthened by Laves-phase pre-

cipitation (Toda, et al.

[1]

) is shown in

Fig. 3, which demonstrates much lon-

ger creep-rupture life of the developed

steels than that of T92 (9Cr-2W F-M

steel). Because ferritic steels are funda-

mentally free from Type IV failure issues

(premature creep failure at the HAZ)

found in F-M steels and offer advantag-

es in thermomechanical fatigue life in

comparison to all other material types,

such alloy design strategies hold prom-

ise for next-generation high-tempera-

ture structural materials. Development

of alumina-forming austenitic stainless

steels was also presented by one of the

authors (Yamamoto, et al.

[1]

), who pro-

posed a unique approach to provide a

promising oxidation-resistance via pro-

tective, external alumina scale instead

of using conventional chromia scales on

commercially available stainless steels.

GAS TURBINES

With regard to coatings, new ma-

terials that can overcome the tempera-

ture limit (1200°C) of partially stabilized

zirconia (YSZ) have been researched for

several decades. Gadolinium zirconate

(GZO) coatings fabricated on top of a bot-

tom layer of YSZ (Fig. 4) are among the

options investigated. GZO coatings fea-

ture improved temperature capabilities,

but do not possess the mechanical re-

sistance of YSZ coatings. However, newly

reported double-layer designs overcome

this limitation and show increased spall-

ation lifetime in thermal cycle testing.

Lifetime simulation procedures and test

method development for double-layer

coatings were also reported.

SUMMARY

The 10th Liège Conference on Ma-

terials for Advanced Power Engineering

continues the long-standing tradition

of collaborative European materials re-

search. Environmental concerns, flexi-

ble operation, and energy security are

global issues that necessitate high-

temperature materials development.

The authors were honored to participate

and present some recent U.S. efforts in

the spirit of strengthening worldwide

collaboration.

References

1.

Proceedings of the 10th Liège

Conference: Materials for Advanced

Power Engineering 2014,

J. Lecomte-

Beckers, O. Dedry, J. Oakey, and B.

Kuhn (Eds.), ISBN 978-3-95806-000-5,

ISSN 1866-1793.

www.fz-juelich.de/zb/ openaccess,September 2014.

Fig. 3 —

Creep stress vs. time to rupture curves for 15Cr ferritic steels without Ni (solid circles),

with 1.2%Ni (solid triangles), and 2.0%Ni (solid squares), developed by Toda, et al. Data of

conventional T92 steel (open triangles) are plotted for comparison

[1]

.