A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A R C H

2 0 1 5

3 1

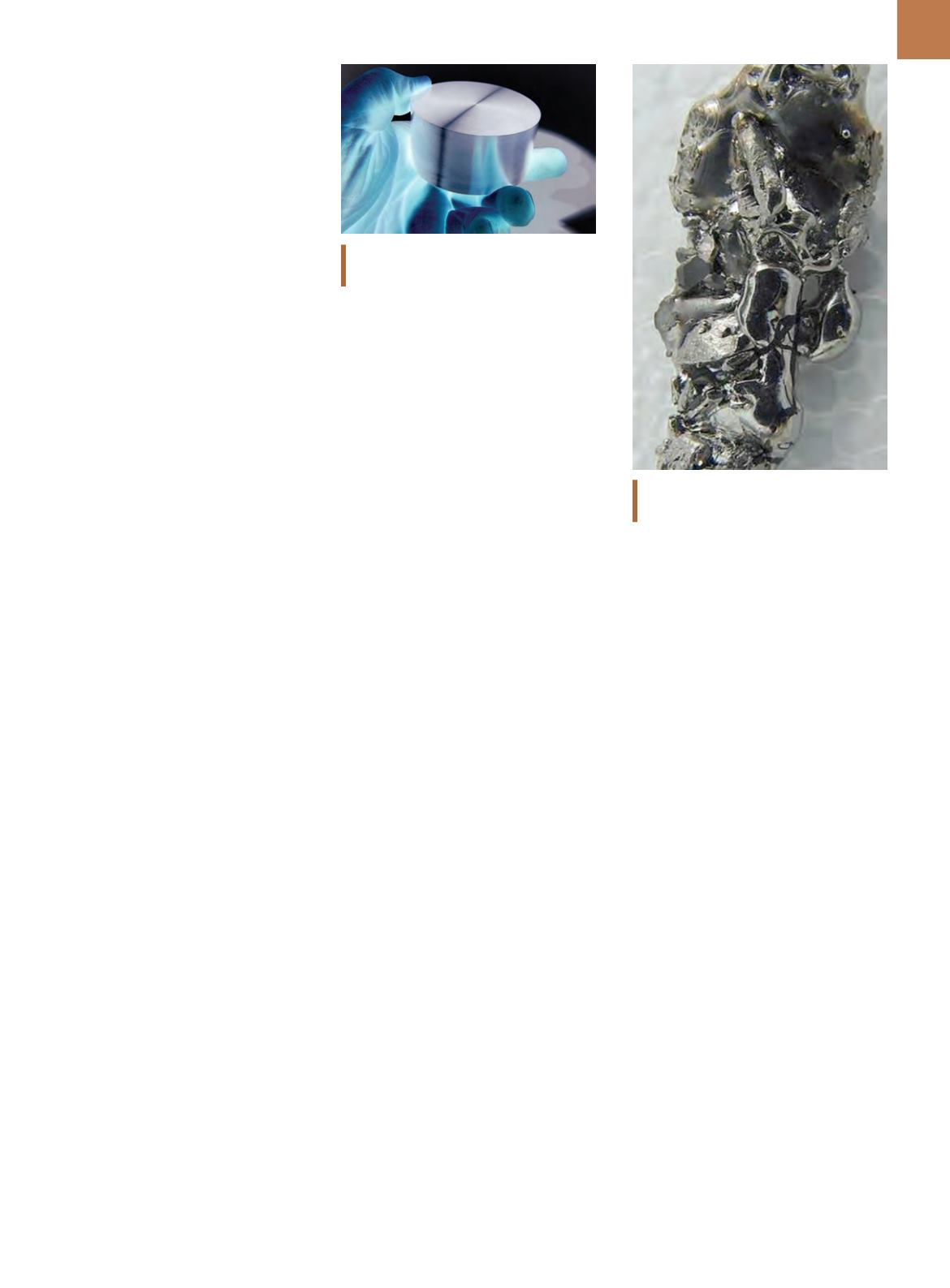

his invention. His process involved a

modification of the sodium reduction

of titanium tetrachloride used by Mat-

thew Hunter at General Electric Corp.

in the early 1900s. Kroll, however, used

magnesium instead of sodium as the

reducing agent. The resulting metallic

product was a spongelike collection

of particles that required removal of

residual magnesium and magnesium

chloride contaminants. After cleaning,

the sponge was crushed to powder,

compacted, and heated at a high tem-

perature to sinter it into a solid mass.

BUREAU OF MINES RESEARCH

The U.S. Bureau of Mines (BOM)

began investigating Kroll’s process at

the Salt Lake City Experimental Station

duringWWII. Titaniumwasmade in 15-lb

batches by 1944. The first steps beyond

the BOM work occurred in 1946 when a

contract was awarded to Battelle Memo-

rial Institute in Columbus, Ohio, to study

the properties, welding, and fabrication

characteristics of titanium and its alloys.

BOM supplied the titanium, with funding

covered by the U.S. Air Force by way of

Douglas Aircraft Co. Every branch of the

armed forces—as well as all government

agencies with an interest in this new

metal—eagerly followed the research

work at Battelle through its progress

reports. This was the first broad scope,

independent research to evaluate titani-

um’s practical capabilities.

After a two-year study, a final clas-

sified report was issued in 1948 con-

cluding that titanium and its alloys had

great engineering potential and further

development should be pursued. This

report and other evidence from work

at the BOM, Wright-Patterson Air Force

Laboratory, and the Army Ordnance

Dept. at Watertown Arsenal provided

the foundation for promoting a new in-

dustry based on titanium. E.I. du Pont

de Nemours and Co. (DuPont) was the

first commercial organization to com-

mit resources to producing titanium. In

late 1948, DuPont sold titanium sponge

for $5 per lb from its production of 100

lb per day. The Remington Arms division

of DuPont conducted research on metal

made from this sponge and would later

be amajor partner in producing titanium

for the aerospace market.

Titanium strips inside a glass jar. Courtesy

of Wikimedia Commons.

A titanium cylinder. Courtesy of Wikime-

dia Commons, Alchemist-hp.

FIRST TITANIUM CONFERENCE

The first major conference on tita-

niumwas held in Washington on Decem-

ber 16, 1948. It was organized by Nathan

Promisel of the Navy’s Bureau of Aero-

nautics and Julius Harwood of the Office

of Naval Research, and held at the Na-

tional Academy of Sciences. Thismeeting

is considered titanium’s official debut.

Many factors came together at this time

that influenced all levels of government

to cooperate in this endeavor. All through

WWII there were shortages of certain ma-

terials vital to the war effort. Metals such

as tungsten, nickel, chromium, manga-

nese, and others were controlled by the

War Production Board and released on

priority bases for only the most import-

ant applications. The initiation of Korean

hostilities in June 1950 provided addi-

tional incentive to develop a new metal

withsuchpromisingproperties and ready

availability in the U.S. It was believed at

this time that the U.S. was self-sufficient

in rutile, the major ore of titanium.

When sample quantities of BOM

material became available, they were

distributed to interested laboratories

across the country including those of

the Army, Navy, and Air Force, as well as

some industrial companies, such as the

National Lead Co. and Kennecott Copper

Co. Studies revealed properties of imme-

diate interest, notably corrosion resis-

tance and strength. It was further sug-

gested that titanium might replace both

aluminum and steel in many defense

applications. Enthusiasm for titanium

reached the highest levels at the Depart-

ment of Defense where funding was ob-

tained for further research and develop-

ment. One of the earliest studies in the

search for alloys with superior mechan-

ical properties was the Rand Program

of the Air Force Materiel Command. This

program financed a laboratory project

at Battelle Memorial Institute to study

a wide range of alloy additions for their

effect on both the physical and mechan-

ical behavior of titanium.

STEEL INDUSTRY INTEREST

Several steel producers

began to

show interest in titanium including Al-

legheny Ludlum Corp., Crucible Steel

Co., Republic Steel Corp., and Sharon

Steel Co. These companies were attract-

ed to titanium for its excellent properties,

which might be exploited as new busi-

ness, and also because titanium could

become a serious competitor to their

regular business, stainless steel. During

1949-1950, they bought titanium sponge

from DuPont and turned it into bar and

sheet products. Thematerial was primar-

ily used for testing by various defense

laboratories, universities, and industrial

firms. National Lead Co. came on stream

in 1950 as a second producer of sponge,

taking over sponge production through

a contract with the BOM at the Boulder

City Experimental Station in Nevada. A

newmetals industry was about to form.

For more information:

Charles R.

Simcoe can be reached at

crsimcoe1@gmail.com.