A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A R C H

2 0 1 5

2 7

For more information:

John Shin-

gledecker is programmanager, Fossil

Materials & Repair Program, Electric

Power Research Institute, 1300 West

W.T. Harris Blvd., Charlotte, NC 28262,

704.595.2619,

jshingledecker@epri.com,

www.epri.com.Acknowledgment

Authors acknowledge the support of the

Crosscutting Research Program, Office

of Fossil Energy, U.S. Department of En-

ergy (YY and AS); and the German Fed-

eral Ministry of Education and Research

and the Helmholtz Association (BK). This

submission was written by the authors

acting in their own independent capac-

ity and not on behalf of UT-Battelle LLC,

or its affiliates or successors.

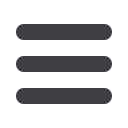

Thermocycles, decreasing GZ0 porosity

1800

1600

1400

1200

1000

800

600

400

200

0

Single layer YSZ

YSZ/GZO (300A-75mm)

YSZ/GZO (325A-75mm)

YSZ/GZO (325A-65mm)

YSZ/GZO (325A-75mm)

YSZ/GZO (450A-75mm)

YSZ/GZO (525A-75mm)

Cycles to failure at 1400°C

Fig. 4 —

Burner rig test results of GZO-YSZ double-layer systems and standard YSZ tested at a

surface temperature of 1400°C

[1]

.

5021MPQR_3.25x4.875 ASM

www.masterbond.com • One part no mix system • Tensile strength >12,000 psi • Used in flame spray coating tests • Dimensionally stable Hackensack, NJ 07601 USA • +1.201.343.8983 • main@masterbond.com High Strength Epoxy EP15 Watch Our Video! going strong