A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A R C H

2 0 1 5

2 1

front seat weight by approximately 8 kg

(Fig. 3). TheMMLV design includes a 12 kg

(42%) reduction in the rear seat by use of

carbon fiber composite structures and

reduced weight foam and fabric trim.

The instrument panel beam uses

carbon fiber composites with integrat-

ed HVAC ducts and chemically foamed

nonstructural parts to reduce weight by

8 kg (36%) from the 2013 Fusion instru-

ment panel beam. Figure 4 shows the

Fusion and instrument panel designs

and materials.

CHASSIS

The MMLV design chassis system

boasts an overall 98 kg (28%) weight re-

duction from the 350 kg Fusion chassis.

The wheels and tires subsystem is 39 kg

(38%) lighter than the 103 kg Fusion.

This is achieved by eliminating the spare

wheel and tire, plus reducing the road

wheels and tire weight. The MMLV design

incorporates 5J×19 wheels and a tire de-

signandmaterial change from225/50R17

to 155/70R19. The wheel weight was set

at 7.5 kg per wheel, which is achieved

with efficient cast aluminum or carbon

fiber designs. The Fusion 7.5J×17 cast

aluminum wheels weigh 10.74 kg each.

(Note: The MMLV prototype includes car-

bon fiber 5J×19 wheels at 6.15 kg each,

Fig. 6.) The tire size change saves 3.35 kg

(29%) per tire from the Fusion—down to

8.25 kg for the MMLV tires.

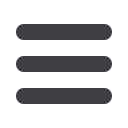

The subframe designs reduce

weight by 27 kg (47%) by using cast and

extruded aluminum instead of stamped

Fig. 5 —

MMLV front and rear aluminum subframes.

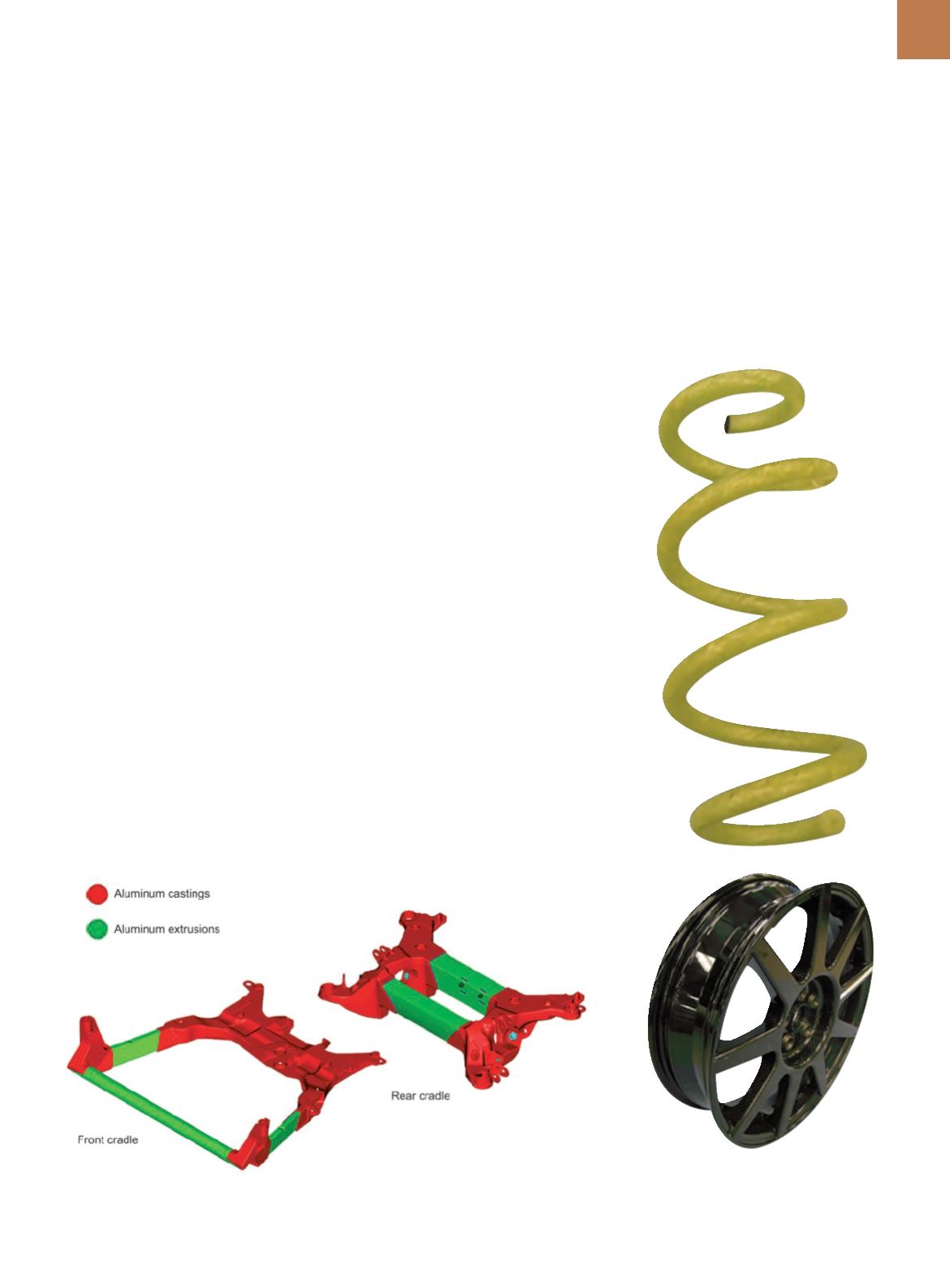

Fig. 6 —

MMLV glass fiber composite spring

and carbon fiber wheel.

steel. The front subframe castings are

high-pressure die castings, while the rear

subframe side castings are low-pressure

hollow castings. The aluminum extru-

sions are MIG (metal inert gas) weld-

ed to the castings. Figure 5 shows the

MMLV subframe designs and materials.

The front and rear suspensions

for the MMLV design include hollow

steel stabilizer bars that save 1.7 kg

(39%) in the front and 2.9 kg (59%) in

the rear, reduced weight knuckles and

shocks from material substitutions of

aluminum for steel, and lightweight

coil springs. Glass fiber-epoxy compos-

ite springs are used in the front while

hollow steel springs are used in the

rear. The composite front spring weighs

1.2 kg vs 2.8 kg—a 57% savings. The hol-

low steel rear spring reduces the weight

by 1.6 kg and results in a 37% savings

(from 2.7 kg vs 4.3 kg).

An 11 kg weight savings in the

brake systems comes from materials

substitution. Traditional cast iron brake

rotors were replaced with cast alumi-

num rotors with a 1-mm-thick, thermal-

ly sprayed two-wire arc stainless steel

alloy coating to provide a durable and

wear resistant surface. Figure 7 shows

the aluminum cast front rotor and the

prototype thermal spray process.

Other weight savings in the chas-

sis system include reductions in the ca-

pacity for the steering system, replacing

the jack systemwith a flat tire repair kit,

and anticipated reductions in fasteners

due to use of lighter components.

POWERTRAIN

The MMLV design powertrain saves

73 kg (21%) over the current production

engine used in the 2013

Ford Fusion.

The Fusion control model has a 1.6-liter

four-cylinder gasoline turbocharged

direct injection (EcoBoost) engine and

6F35 six-speed automatic transmission.

The new MMLV design incorporates a

1.0-liter three-cylinder gasoline turbo-

charged direct injection (Fox EcoBoost)

engine with a lightweight design and

a lighter 6F15 six-speed automatic