A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A R C H

2 0 1 5

1 9

A

new multi-material lightweight

vehicle (MMLV) design demon-

strates the potential for light-

weighting of a five-passenger sedan

while maintaining critical vehicle perfor-

mance and occupant safety metrics. The

design incorporates commercially avail-

able materials and production process-

es, achieving a 364 kg (23.5%) full vehicle

mass reduction compared to the 2013 Fu-

sion baseline. In turn, this weight savings

enables use of a 1.0-liter three-cylinder

engine, significantly improving fuel econ-

omy and reducing CO

2

emissions. This

article explores the vehicle design and

material usage details, systemby system.

Over the past 20 years, numerous

studies have investigated the impact of

mass reduction on vehicle fuel efficien-

cy. Generally, a 10% reduction in vehi-

cle mass improves fuel efficiency by ap-

proximately 3-4%. However, whenmass

decompounding is applied, i.e., the op-

portunity to further reduce powertrain

and chassis system weight, a 6-7%

improvement in fuel economy can be

realized while maintaining vehicle per-

formance. The 364 kg weight reduction

from the baseline 2013 Fusion results

from redesigning and lightweighting

five vehicle systems including the body

and closures, interior, chassis, power-

train, and electrical components.

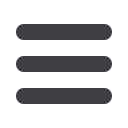

Table 1 describes weight reduc-

tions according to the major systems

within each vehicle subsystem. The

MMLV project allows functional and

drivable vehicles to participate in se-

lected performance tests. Durability,

crash, corrosion, and NVH (noise, vi-

bration, and harshness) tests enable

the design team to ensure that the

weight-reduced vehicle meets specified

requirements.

Magna International led design

efforts on the body-in-white, closures

and bumper structures, subframes and

control arms. Ford designed the power-

train, select chassis components, inte-

riors, electrical, and all other systems.

Referencing the 2013 Fusion, Magna was

responsible for the lightweight design

of components and systems weighing

approximately one-third of the 1559 kg

curb weight. The Ford team was re-

sponsible for the lightweight design

TABLE 1 —MMLV DESIGN WEIGHT DISTRIBUTION BY VEHICLE SUBSYSTEM

Subsystem description, kg

2013 Fusion

MMLV Mach-I

design

Body exterior and closures

594

456

Body-in-white

326

250

Closures-in-white

98

69

Bumpers

37

25

Glazings – fixed and movable glass

37

25

Misc. – trim, mechanisms, paint, seals, etc.

96

87

Body interior and climate control

207

161

Seating

70

42

Instrument panel

22

14

Climate control

27

25

Misc. – trim, restraints, console, etc.

88

80

Chassis

350

253

Front and rear suspension

96

81

Subframes

57

30

Wheels and tires

103

64

Brakes

61

49

Misc. – steering, jack, etc.

33

29

Powertrain

340

267

Engine (dressed)

101

71

Transmission and driveline

106

92

Misc. – fuel, cooling, mounts, etc.

133

104

Electrical

69

59

Wiring

28

25

Battery

14

8

Misc. – alternator, starter, speakers, etc.

27

26

Total vehicle weight

1560

1196

Weight saved compared to 2013 Fusion = 23.3%.

of components and systems weighing

approximately two-thirds of the 2013

Fusion curb weight.

BODY EXTERIOR

AND CLOSURES

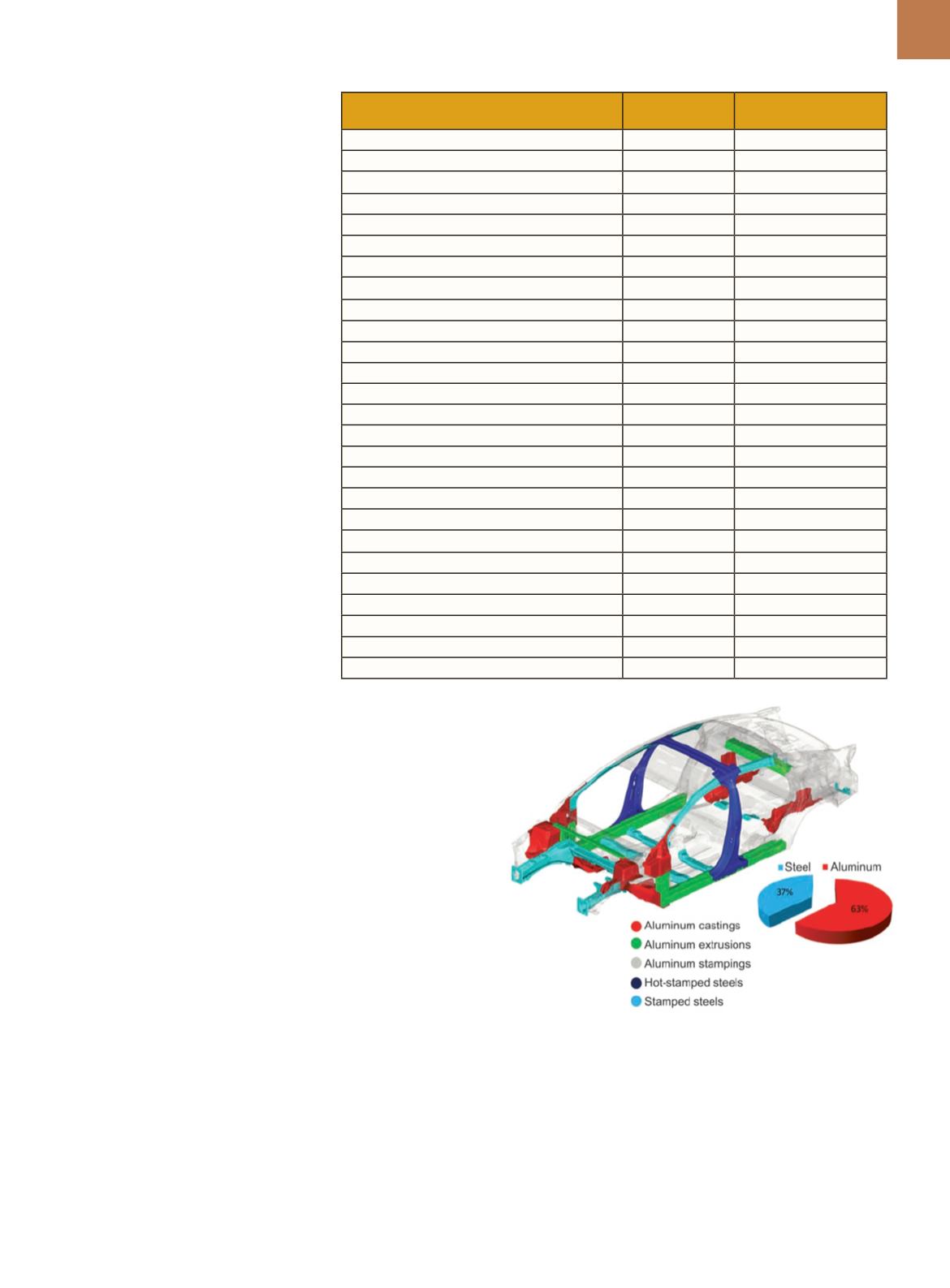

The body-in-white

and closures-in-white

account for 424 kg of the 594 kg in

the 2013 Fusion. Magna designed

the body-in-white with all three forms

of aluminum: sheet, extrusion, and

castings. Advanced high-strength steel

sheet was used for the primary safety

structures such as crush rails, b-pillars,

and selected cross car beams. The re-

sulting design weighs 250 kg—a savings

of 76 kg (23%). Figure 1 shows the body

structure with material distribution.

The new MMLV design includes ex-

trudedaluminumbumper andcrushcans

at 11.1 kg (6.2 kg front and 4.9 kg rear)—a

savings of 9.3 kg (46%) from the prior

Fig. 1 —

MMLV design body-in-white mixed

aluminum and steel.

bumper structures. The fascia systems

for the design also include chemically

foamed plastic covers, which shave 2.1 kg

(13%) from the previous fascia systems.

The side doors, fenders, and deck

lid are primarily made of aluminum

with boron steel intrusion beams and