ADVANCED MATERIALS & PROCESSES •

SEPTEMBER 2014

24

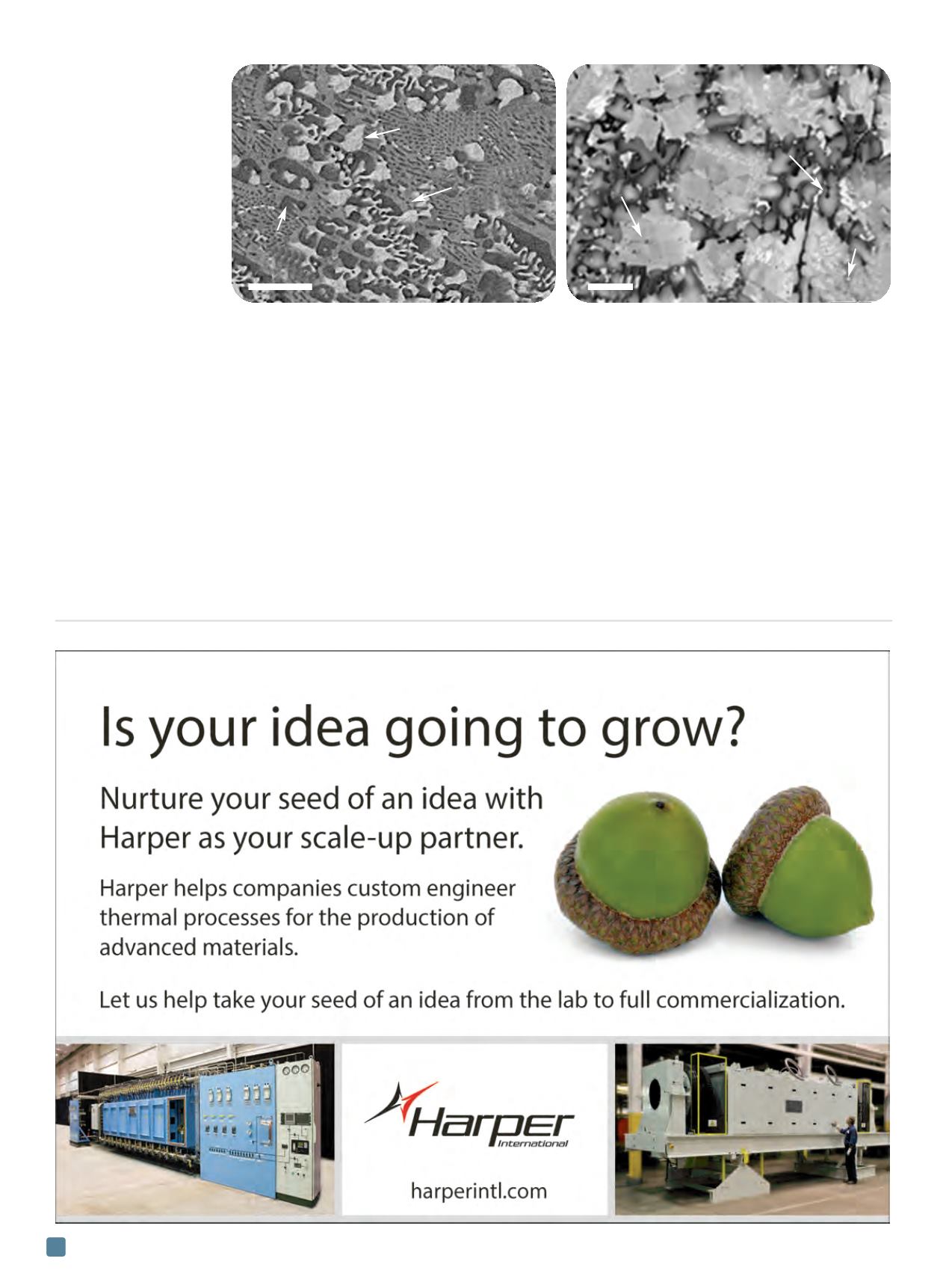

useful toughness (Figs. 2 and 3a). The processing routes to

synthesize this microstructure are based on innovative pow-

der processing and directional solidification

[14-16]

. Recent de-

velopments include incorporation of TiC particle

dispersions that enhance high temperature mechanical

properties, reduce density to levels comparable to levels

for Ni-base superalloys, and facilitate casting

[17]

. To achieve

full density in powder processing, minor additions of ele-

ments such as Fe promote rapid sintering. The borosilica

scale that develops during high temperature oxidation pro-

vides some protection, but the recession rate must be re-

duced, and at low temperature (i.e., 700°C) a pesting

reaction develops before the borosilica can provide full

coverage

[18]

. Both low and high temperature oxidation re-

actions can be inhibited by a pack cementation coating in-

volving codeposition of B and Si that also resists calcia-

magnesia-alumina-silica (CMAS) and water vapor at-

tack

[19,20]

.

For Nb silicides, the main alloy constitution is based on

the Nb-Si-Ti system, but also includes additions of Cr and

Hf. The main microstructure phases include Nb(ss) and

Nb

5

Si

3

with minor amounts of an NbCr

2

Laves phase (Fig.

3b)

[10]

. The Nb

5

Si

3

phase features a structure of either the

T

1

or T

2

phase in the Mo-Si-B system (Fig. 2) depending on

temperature and composition. Again, this microstructure

can be achieved through either powder processing or by

solidification. However, inadequate oxidation resistance

remains a significant issue with Nb-base alloys. Recent

progress reveals that silicide surface layers formed due to

oxidation of an Nb

3

Fe

3

CrSi

6

phase offer the potential to

Fig. 3 —

SEM backscat-

tered image of as-cast

Mo-14.2Si-9.6B (a),

directionally solidified

Nb alloy (Nb-19Ti-2Hf-

13Cr-2Al-4B-16Si) with

dispersions of (Nb)

5

Si

3

and

(Nb)Cr

2

(b).

(a)

Mo (white)

Mo

3

Si (grey)

T

2

(dark)

10 µm

(b)

Laves

(Nb)

5

Si

3

(Nb)

100 µm