ADVANCED MATERIALS & PROCESSES •

SEPTEMBER 2014

19

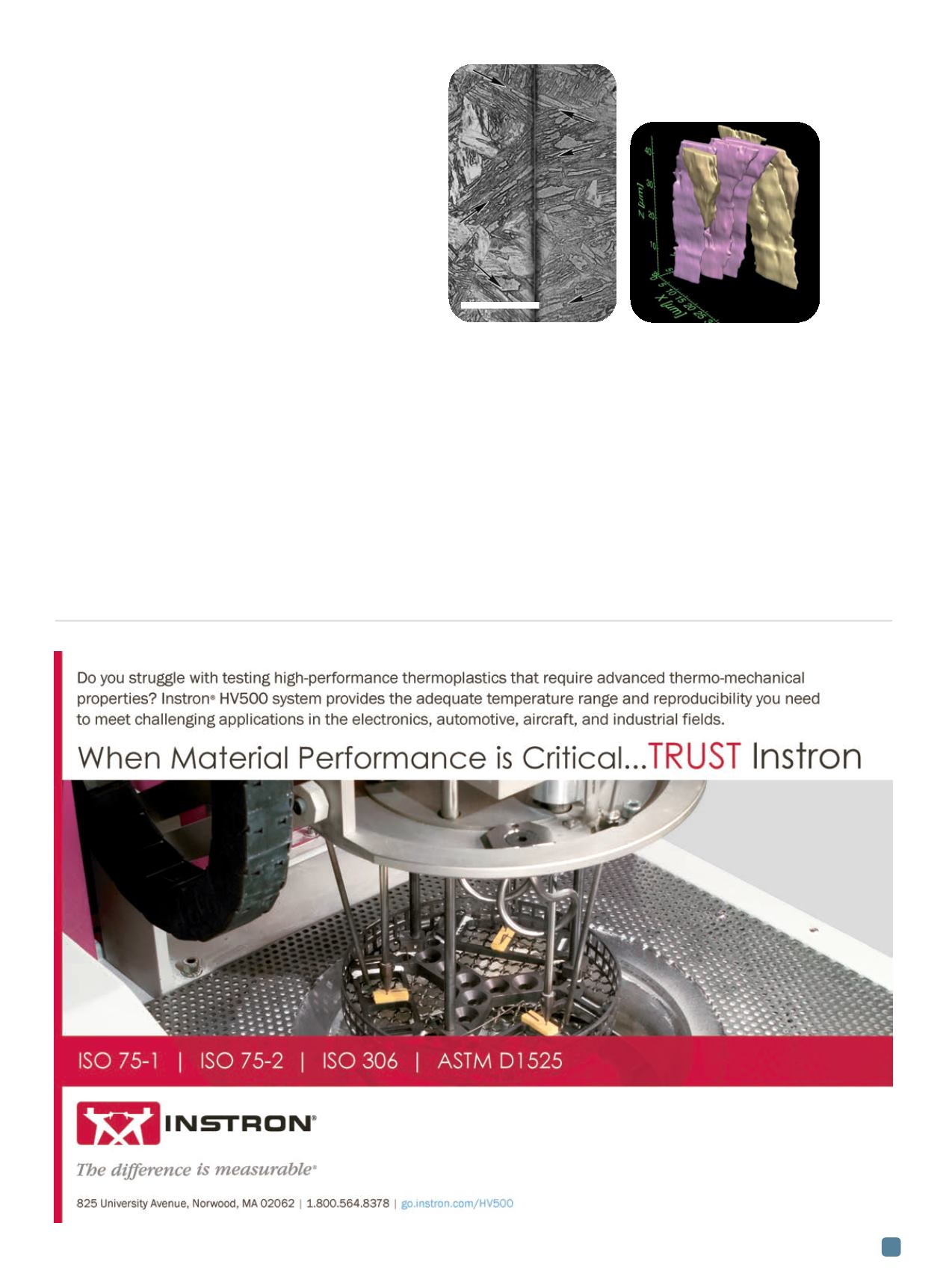

3D reconstruction. This reconstruction demonstrated

that all precipitates within the grain interior had a sim-

ilar lath morphology connected to the grain boundary

cementite film. In other words, the morphologies iden-

tified from the 2D analyses as Widmanstatten sideplates,

intragranular Widmanstatten precipitates, and intra-

granular idiomorphs were actually a single precipitate

morphology—a Widmanstatten sideplate. The different

apparent morphologies observed on the 2D surface re-

sulted from sectioning these Widmanstatten precipi-

tates in different orientations.

The 3D reconstruction of the grain boundary cemen-

tite precipitate film exhibits an unexpected characteristic—

holes in the grain boundary films appeared more irregular

than expected from the growth and impingement of allotri-

omorphic precipitates. Etching away the matrix to expose

the cementite grain boundary film demonstrates that grain

boundary precipitates initially exhibit a dendritic morphol-

ogy instead of the classical allotriomorphic morphology re-

ported from 2D analyses. Further precipitation causes

impingement of the dendrite arms to form the observed

grain boundary film. Random 2D cross-sections of the

dendritic structure reveal a row of dendrite arm cross-sec-

tions, appearing to be isolated allotriomorphs at the grain

boundary. Only 3D analysis allows the correct dendritic

morphology to be identified.

Coarse martensite case study

Another example of the importance of 3D analysis for ac-

curate determination of microstructural features involves a

coarse martensitic component observed in low carbon

steels

[8]

. This coarse martensite, called

coalesced bainite

by

some researchers

[9]

, typically exhibits a flat interface at one

end and either a rough face or a tapered morphology at the

other. Analysis of coarse martensite on two perpendicular

faces of the sample, as in Fig. 4a, demonstrate that individ-

ual precipitates can exhibit large dimensions in those two di-

rections, indicating a plate morphology. In addition, the

Fig. 4 —

Optical micrographs from two perpendicular surfaces

showing typical appearance of the coarse martensite on each

face and selected martensite constituents with large

dimensions on both faces (a), and 3D reconstruction of two

coarse martensite orientations (b, indicated by color).

40 µm

(a) (b)