make poor assumptions such as spherical grain shapes.

However, the increase in 3D microstructural analysis has

led to a number of datasets that can make direct compar-

isons to these models. One example shown in Fig. 1 is the

serial sectioning of a β-titanium alloy, wherein 200 serial

sections spaced 1.5 μm apart were stacked to reconstruct

the grain morphology of more than 4000 grains.

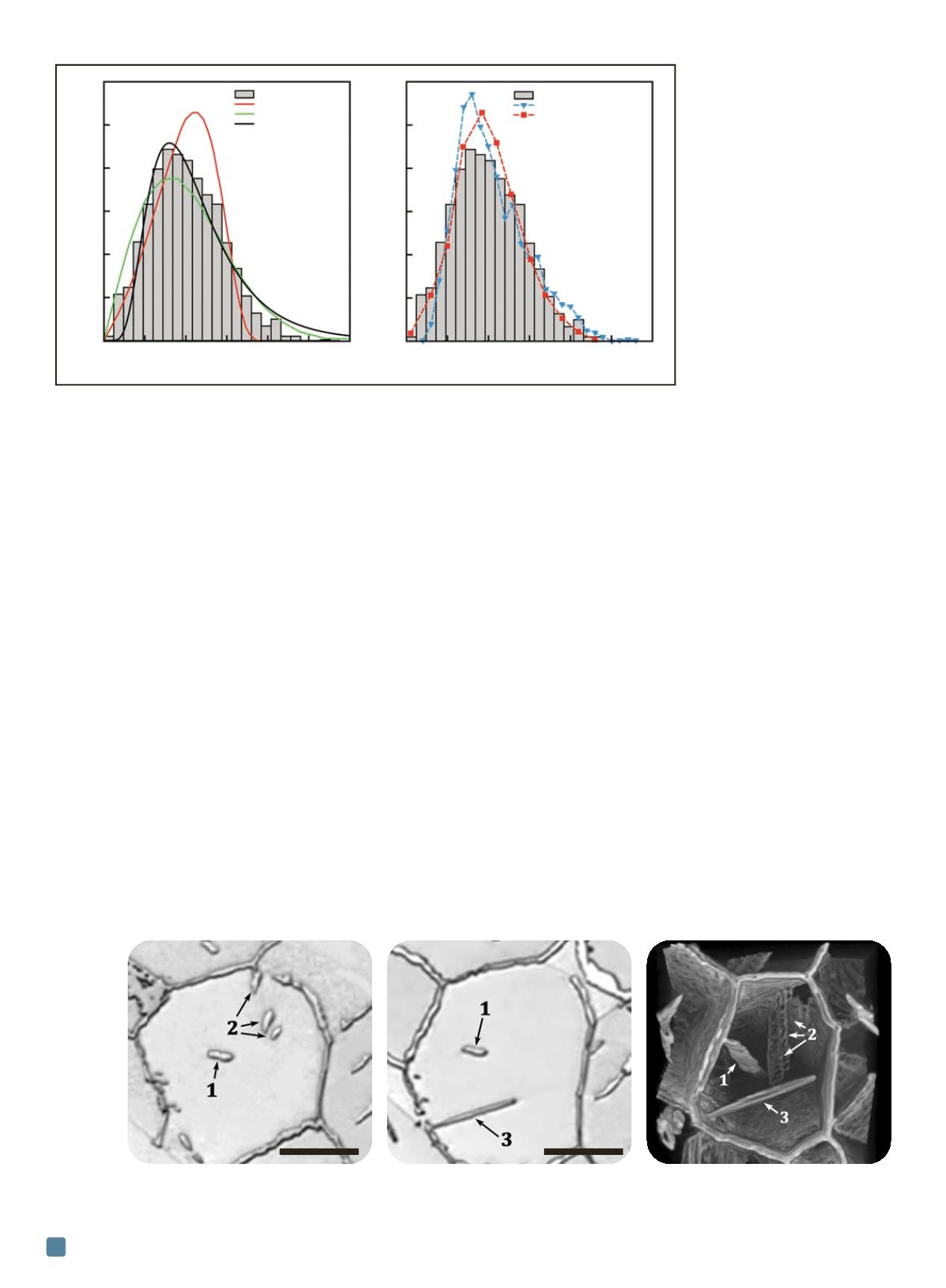

Figure 2 plots the normalized grain size distribution

and shows significant differences between the models and

the experimentally determined distribution of equivalent

sphere radii

[4]

. While the log-normal distribution fits the

peak of the distribution well, it underestimates the number

of small grains and significantly overestimates the number

of large ones. Because a material’s mechanical behavior re-

lies more heavily on the smaller and larger tails of the grain

size distribution, such variations are not acceptable.

Further discrepancies exist between this data and the

two grain growth theories developed by Hillert and

Louat. The Hillert distribution predicts a much sharper

distribution, severely underestimating the number of

large grains, while the Louat distribution is much

broader, predicting a much larger population of smaller

grains. Other 3D data sets acquired of the grain struc-

tures in a nickel-base superalloy

[5]

and recrystallized

alpha iron

[6]

demonstrate similar shortcomings of these

models in reproducing the important tails of grain size

distributions. What is unclear

from the small collection of

3D experimental data is

whether grain size distribu-

tion is somewhat common for

all alloy systems, or if there

are significant deviations

from these distributions that

depend on intrinsic proper-

ties (such as interfacial energy

anisotropies) or extrinsic con-

ditions (such as degree of cold

work before recrystallization).

Cementite precipitate

morphology case study

The differences between the

expectations derived from 2D analyses and the reality re-

vealed through 3D analyses become more evident when

dealing with complex shapes, connectivities, and

nonuniform distributions. This was demonstrated in an

early 3D study by Kral and Spanos

[7]

. Analysis of cemen-

tite morphologies that were visible on 2D section sur-

faces was performed and is shown in Fig. 3a-b. From this,

it was concluded that cementite precipitates form in a

variety of morphologies, with the prevalent morpholo-

gies being grain boundary allotriomorphs (which im-

pinge to form grain boundary films), Widmanstatten

sideplates, intragranular Widmanstatten precipitates,

and intragranular idiomorphs.

Grain boundary allotriomorphs are oblong precipi-

tates, generally viewed as two abutting spherical caps, lo-

cated at the grain boundary that grow to impinge each

other and form a continuous film along the grain bound-

ary as precipitation progresses. Widmanstatten sideplates

are elongated precipitates that nucleate at the grain bound-

ary and extend into the matrix. Elongated precipitates that

lie wholly within the grain are called intragranular Wid-

manstatten plates. Idiomorphs are equiaxed precipitates

typically located within the matrix grain, but occasionally

located at the grain boundary.

Figure 3c shows the actual 3D microstructure of this

alloy, which was revealed through serial sectioning and

ADVANCED MATERIALS & PROCESSES •

SEPTEMBER 2014

18

Fig. 2

—

Comparisons between the equivalent sphere radius grain sizes obtained from

b

-titanium

3D reconstruction and grain size distributions predicted by common models (left) and measured

in other alloys (right).

Fig. 3

—

Optical micrographs of cementite precipitation in an austenite grain, showing different morphologies and connectivities to

the grain boundary of the cementite precipitates (a, b), and 3D reconstruction of that grain demonstrating that all intragranular

precipitates have the same morphology and connectivity (c).

(a)

(b)

(c)

10

m

m

10

m

m

0 0.5 1.0 1.5 2.0 2.5 3.0

R/<R>

0 0.5 1.0 1.5 2.0 2.5 3.0

R/<R>

Ti-21S

b

grains

Ni grains (Groeber 2008)

Fe grains (Zhang 2004)

Ti-21S

b

grains

Hillert (1965)

Louat (1974)

Log normal

1.2

1.0

0.8

0.6

0.4

0.2

0

1.2

1.0

0.8

0.6

0.4

0.2

0

Frequency

Frequency