processing steel

[6]

. They demonstrated exceptional oxida-

tion lifetimes with oxide dispersion strengthened Fe

3

Al,

but the relatively high thermal expansion coefficient for

Fe

3

Al and FeAl makes system design a challenge

[7]

. A new

wave of research is now investigating new aspects of these

aluminides. For example, for Fe-Al alloys, a eutectoid reac-

tion from Fe

5

Al

8

to an ultrafine (<100 nm) lamellar struc-

ture of FeAl

2

and FeAl yields a microstructure that can

rapidly form a passivating α-Al

2

O

3

scale upon oxidation

without any internal oxidation.

Advances in strengthening phases

Another advance for intermetallics involves applying

a wider range of strengthening phases for Fe- and Ni-base

alloys. In Ni-base superalloys, the principal strengthening

phase has always been γ’ (Ni

3

Al). However, in a number

of alloy compositions such as alloy 263, the η (Ni

3

Ti)

phase also develops after long-term exposure. Based on a

thermodynamic modeling analysis, composition modifi-

cations involving small additions of V and Ta yield an

increase in the η phase volume fraction above 750°C from

5% up to 15%, which is expected to increase the high tem-

perature strength.

Application of

s

phase in new steels for ultra-super-

critical steam power generation is another surprising de-

velopment. Usually,

s

phase formation is very sluggish so

that it only develops in a microstructure after hundreds of

hours of high temperature exposure and coincides with a

shortening of the rupture life. However, with cleverly de-

signed alloys and annealing processes, when

s

phase is dis-

persed along grain boundaries, it can serve as a valuable

microstructural component to enable a significant en-

hancement of creep resistance.

In a similar manner, austenitic steels strengthened with

Heusler phases, Fe

2

Nb laves phase, NiAl, and Ni

3

Al pre-

cipitates are potential candidates to economically provide

high strength and corrosion resistance for service above

700°C

[8]

. In this case, thermomechanical treatments are

used to produce a refined and uniformly dispersed precip-

itate nanostructure in order to achieve enhanced perform-

ance. Further chemistry changes are being investigated in

some high Mn compositions in order to avoid environ-

mental embrittlement. In addition, nanostructured steels

are being developed with high levels of P-group elements.

In order to achieve ultrahigh temperature capability well

beyond the limit of current Ni-base superalloys, refractory

metal silicide intermetallics offer a number of attractive

characteristics. Yet they also present challenges with re-

gard to developing robust environmental resistance and

innovative processing to achieve multiphase microstruc-

ture designs and morphologies with both high tempera-

ture strength and room temperature toughness

[9-13]

.

Processing is an important component in alloy synthesis

because the requirement for high temperature stability

means that microstructure modification following the ini-

tial alloy synthesis is difficult.

For Mo-Si-B alloys, microstructure designs involving a

continuous molybdenum solid solution, Mo(ss) matrix with

dispersions of Mo

3

Si andMo

5

SiB

2

intermetallics can achieve

ADVANCED MATERIALS & PROCESSES •

SEPTEMBER 2014

23

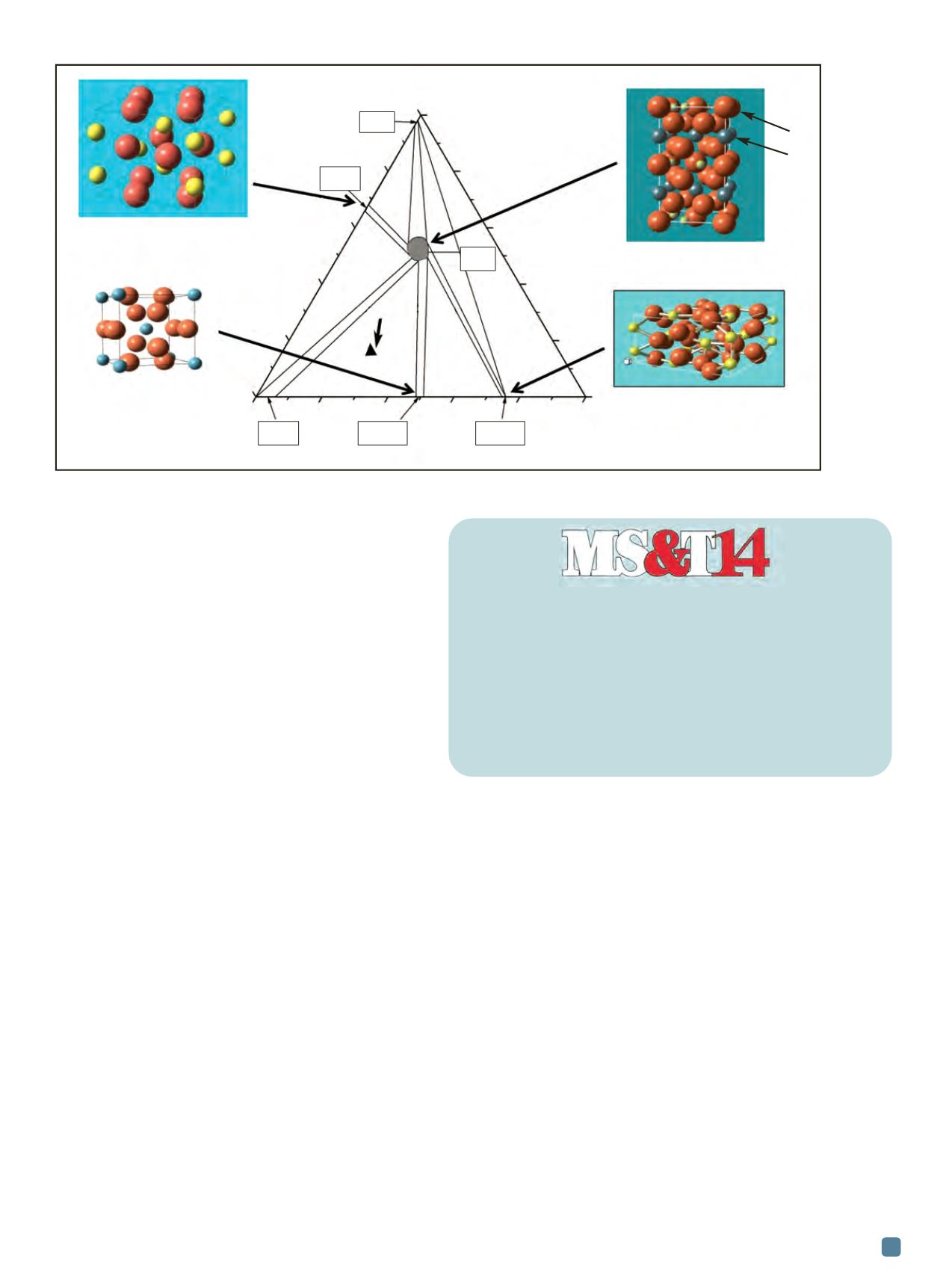

Fig. 2 —

Mo-rich portion of the Mo-Si-B ternary system featuring the Mo bcc (matrix) phase in equilibrium with the borosilicide (T

2

)

and silicide (Mo

3

Si) phase.

Structural Intermetallics Symposium

Structural Intermetallics in Superalloys,

Monday, Oct. 13, 10:20 a.m.

Silicide Intermetallic Systems,

Monday, Oct. 13, 2:00 p.m.

Heat Treatment, Processing, and Characterization

of Intermetallics,

Tuesday, Oct. 14, 8:00 a.m.

Design Approaches for Structural Intermetallics,

Tuesday, Oct. 14, 2:00 p.m.

Poster Session,

Wednesday, Oct. 15, 11:00 a.m.

Mo

2

B (cubic)

Mo

3

Si (A15) (cubic)

T

2

(tetragonal)

Mo

5

Si

3

(T

1

) (tetragonal)

Mo

Si

1600°C

X Mo

X

B

0.0

0.1

0.2

0.3

0.4

0.5

X Si

Mo-14.2Si-9.6B

0.5

0.6

0.7

0.8

0.9

1.0

0.5

0.4

0.3

0.2

0.1

0.0

MoB

T

2

Mo

2

B

Mo

ss

Mo

3

Si

Mo

5

Si

3