Joel J. Schubbe

U.S. Naval Academy

Annapolis, Md.

ADVANCED MATERIALS & PROCESSES •

JUNE 2014

26

F

ounded in 1845 and now the undergrad-

uate college of the Navy, the U.S. Naval

Academy (USNA), Annapolis, Md., pre-

pares young men and women to lead naval

forces as commissioned officers after four years

of classes and training. Because the naval fleet

has changed dramatically since its early days,

the classes and topics students must master in

order to maintain ships have also evolved.

Many organizations within the Department of

Defense (DoD) recognize the importance of the

next generation of leaders and their ability to

address material degradation and corrosion in

the aging—and sometimes irreplaceable—sys-

tems that the armed forces rely on.

The Office of the Secretary of Defense

through the Technical Corrosion Collaboration,

the Naval Research Laboratory, the Air Force Re-

search Laboratory, the Air Force Institute of

Technology, the Naval Air Systems Command,

and others, have all implemented efforts to ad-

dress expanded education efforts and technical

understanding of materials degradation. One of

the goals of the Naval Academy’s corrosion ef-

forts and corrosion-related STEM activities is to

educate students to understand materials degra-

dation processes and prevention methods for

aging defense systems. The USNA has a robust

undergraduate engineering program with many

research opportunities.

Recent corrosion research

Corrosion, corrosion fatigue, fracture and

fatigue, surface treatments, hybrid materials,

and composites are central subjects of the me-

chanical engineering faculty for materials and

mechanics, and have inspired many summer

internships and research projects in recent

years. For example, Peggy LeGrand, as a Bow-

man Scholar, with professor Michelle Koul pur-

sued “Environmentally Assisted Cracking

Evaluation of UNS N06686 Using Constant Ex-

tension Rate Testing” and presented results at

the 2010 NACE Conference.

In addition, Jennifer Jones produced “An

Evaluation of the Corrosion and Mechanical

Performance of Interstitially Surface Hardened

Stainless Steel” and is currently a graduate stu-

dent at University of Virginia studying with

Jimmy Burns. Eric Arnold, an independent re-

search student, with associate professor Joel

Schubbe and professor Patrick Moran pre-

sented work at the 26th ICAF Symposium and

published in the

Journal of Materials Engineer-

ing and Performance

with “Comparison of SCC

Thresholds and Environmentally Assisted

Cracking in 7050-T7451 Aluminum Plate.”

Follow-up work was performed by Martin

Bennett, a recent graduate of the Naval Post-

graduate School.

Battling corrosion fatigue

Corrosion is the most insidious formof dam-

age commonly present in DoD weapon systems

and infrastructures and has many facets. One of

the most dangerous and prevalent is

corrosion

fatigue,

damage that occurs due to cyclic stresses

combined with corrosive environments. It re-

duces the operational life of many systems and

infrastructures, such as aerospace structures,

ships, submarines, and bridges. Catastrophic

consequences can result when corrosion fatigue

is not prevented or corrected.

Midshipmen (MIDN) Sabrina Reyes and

Scott Bolstad, members of the USNA Bowman

Scholar program fostering nuclear expertise of-

ficers, were recently featured in

CorrDefense

Naval Academy Attacks Corrosion

with Education and Research

The U.S. Naval

Academy is

expanding

awareness

about

corrosion-

related

material

degradation,

its effects

on force

readiness,

and efforts to

manage it.

U.S. Naval Academy, Annapolis, Md., founded in 1845.

Fig. 1

—

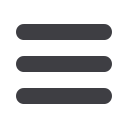

Professor Patrick Moran teaches high

school students about corrosion testing.