while, as China and India prepare to enter the commercial

aerospace market, their new research institutes have in-

vested heavily from the beginning in a full range of dynamic

testing capabilities for both metals and composites.

There is also an increasing demand for very high ca-

pacity servo hydraulic test frames. Although the tests for

which these are used often do not require highly dynamic

performance in terms of frequency or number of cycles,

their use is not confined to high-force monotonic tests. In

this case, the aerospace industry is foremost in generating

this requirement, for two reasons. First, large, high-

strength structures are produced from thick composite

laminates with complex layups; this means that a represen-

tative test specimen must often be the full thickness, and

only a finite width reduction is possible without undue in-

fluence of specimen edge effects. Therefore, if the speci-

men cannot be made smaller, machine capacity must be

higher. Second, for similar reasons, the influence of lami-

nate design and processing means that there is no alterna-

tive but to test entire structural elements.

True progress

There is no doubt that the structural composites mar-

ket is going to keep growing for the foreseeable future. Ar-

guably, some of the most commercially exciting

developments are being achieved through industrial ac-

ceptance of different design needs, which in turn must be

supported by even more rigorous and demanding mechan-

ical testing techniques.

Ultimately, this commercial demand comes from the

power generation and transport industries that are central

to our era, because they must now evaluate various aspects

of the dynamic performance of composites in order to use

them in safety critical, moving structures.

For more information:

Peter Bailey is senior applications spe-

cialist, Instron, Coronation Rd., High Wycombe, Bucks HP12

3SY, UK, 44.1494.464646,

info@instron.com,

instron.us.

ADVANCED MATERIALS & PROCESSES •

JUNE 2014

21

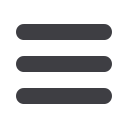

Fig. 4 —

Comparison of maps of axial strain from DIC (left) and local stress

from TSA (right) on the same specimen giving complementary information.

An impact-damaged composite specimen was subjected to fatigue loading.

Courtesy of Crump et al., Engineering Integrity, No. 35.

5 x 10

-3

D

T/T

0

5

4

3

e

yy

(%)

2

1

0