ADVANCED MATERIALS & PROCESSES •

JUNE 2014

29

completely eliminated. Taking all measurements from the

exact same point on the web prevents measurement errors

caused by nonflat base substrates, sheet flutter, and ambi-

ent light change.

Because full spectrum IR web gauging sensors lack the

moving parts of a filter wheel, they have significantly fewer

possible failure points. This makes themmore reliable and

less likely to require maintenance. They can also be easily

recalibrated for new material measurements via software

and require no hardware or filter changes.

Chemometrics software like that offered by Thermo

Scientific, Waltham, Mass., called EZCal, offers easy recal-

ibration for maximum product measurement flexibility.

Using a broad set of mathematical manipulation tech-

niques, this software can analyze complex sets of overlap-

ping spectra to provide accurate measurements of mono-

and multi-component webs. It also eliminates the effects

of printing and additives, which can cause spinning filter

wheel sensors to provide inaccurate measurements.

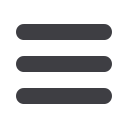

In a full spectrum measurement, web component

thickness is determined by measuring total absorption

across the material’s unique fingerprint. Figure 2 shows an

example of the absorption pattern for a given material,

with thicknesses varying from 5-25 µm. Typically, graphs

like this are only seen in an FSIR instrument’s output in di-

agnostic mode. Most of the time, the chemometrics soft-

ware performs thickness analysis on its own and provides

an easy-to-read figure for each web component. Accurate

multi-component analysis offered by full spectrum IR web

gauging instruments makes them well suited for both sim-

ple and complex web process monitoring applications, in-

cluding cast film, biax film, extrusion coating and

laminating, blown films, and nonwovens.

A typical multilayer blown filmmay contain skin layers

of polyethylene (PE), a barrier layer of ethylene vinyl alco-

hol (EVOH) or Surlyn, and tie layers. For this application,

a full spectrum IR sensor analyzes the spectra of the mul-

tilayer structure and is able to separate the thicknesses of

each material across the entire web. Full spectrum IR sen-

sors also excel in multilayer extrusion coating and lamina-

tion applications, as they are capable of accurately

measuring thin layers of polyethylene terephthalate (PET),

PE, and polyacetylene (PA) simultaneously, for example.

Applications

Production of nonwovens, including spunbond, spun-

lace, spunlaid, and airlaid webs, is a good application for

full spectrum IR web gauging technology. Applicable ma-

terials measurements for analysis of nonwovens include

polyethylene (PE) or polypropylene (PP) fibers, latex

binders, superabsorbent polymers/materials, and total

basis weight. Full spectrum IR instruments can also contin-

uously monitor the moisture content of nonwoven materi-

als—important for nonwovens with personal hygiene,

medical, and geotextile purposes.

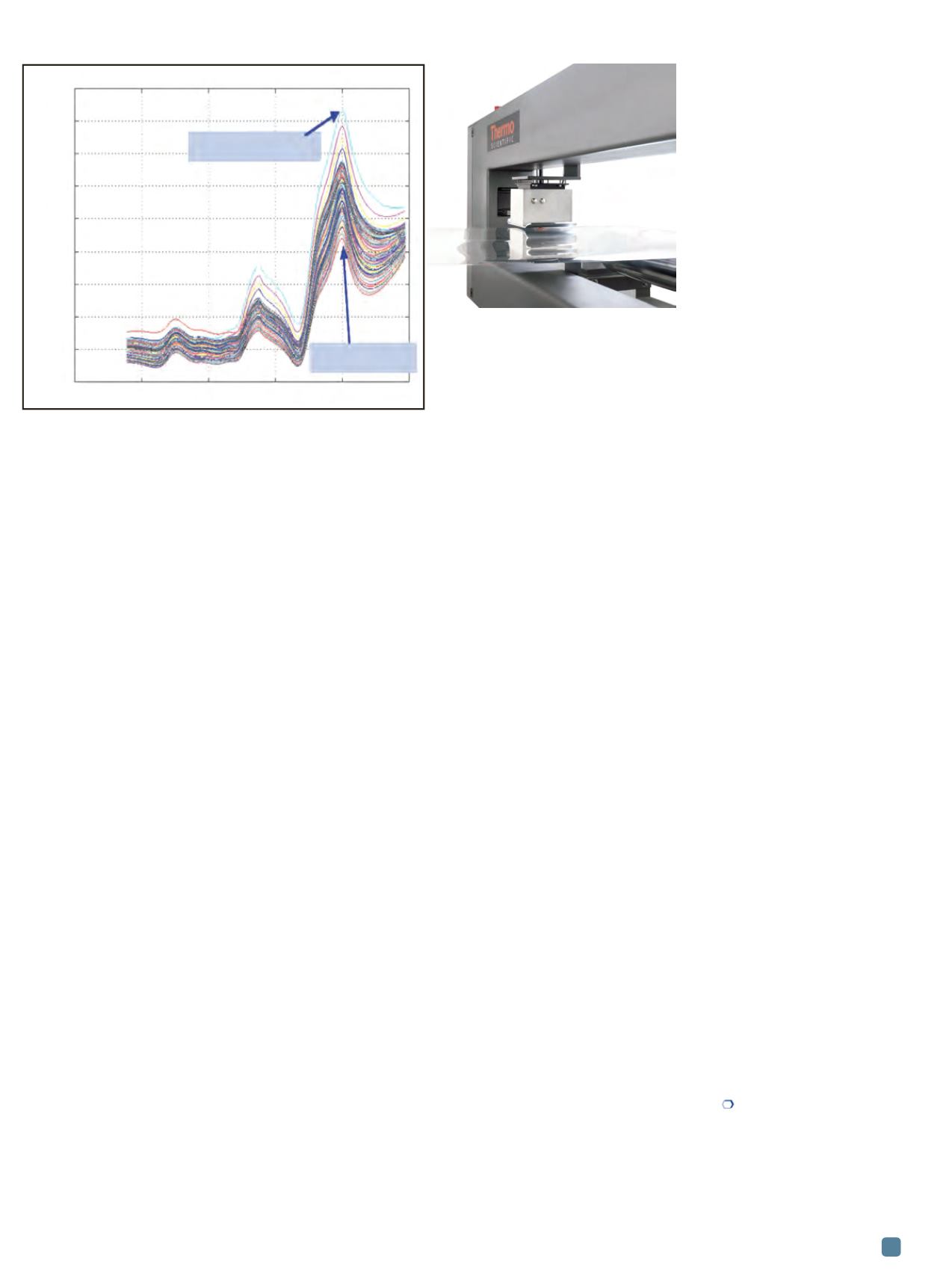

In addition to a transmission mode that measures web

absorption of the NIR spectrum, full spectrum IR sensors

such as Thermo Scientific’s PROSIS can be configured to

measure a web in reflection mode. This configuration ex-

cels at measuring coating thickness on metal sheets or

other opaque substrates. Typical measurements for coated

metal sheets include top and bottom paint thickness, oil

film thickness, and primer or lacquer layers. Reflection

measurements are also useful for tandem extrusion coating

and aseptic packaging production.

Another important application of full spectrum IR sen-

sor technology is lithium ion battery (LIB) production.

Complex multilayer separator films, which separate the

cathode and anode in all LIBs and facilitate the flow of

charged ions, are critical to battery efficiency and lifetime.

Full spectrum IR instruments can help improve thickness

consistency and ensure a more homogenous distribution

of pores in the separation film to maximize performance.

Essentially any web production industry could benefit from

the versatility, ease of use, increased precision, and reduced

maintenance costs of full spectrum IR web gauging instru-

ments. In certain cases, nuclear sensors can also be

switched to full spectrum IR sensors, to reduce regulatory

burdens. Through their full spectral response measure-

ment capabilities and advanced chemometrics analysis

technique, full spectrum IR thickness sensors enable pro-

duction of more on-spec products and reduce material

waste without compromising profitability.

For more information:

Tam Nguyen is product marketing

manager – web gauging, Thermo Fisher Scientific Inc.,

81 Wyman St., Waltham, MA 02451, 978.663.2300,

tam.nguyen@thermofisher.com,

thermofisher.com.

Fig. 2

—

Absorbance levels for various material thicknesses.

Fig. 3

—

PROSIS IR process

analysis thickness sensor.

1.8

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

0

Absorbance

Infrared absorbance vs. Wavelength

Thickness = 25 µm

Thickness = 5 µm

Wavelength (µm)