edfas.org

41

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 19 NO. 1

PRODUCT NEWS

Larry Wagner, LWSN Consulting Inc.

lwagner10@verizon.netPRESS RELEASE SUBMISSIONS:

MAGAZINES@ASMINTERNATIONAL.ORGFEI OFFERS EFA WORKFLOW

SOLUTIONS

Semiconductormanufacturers can turn to newelectri-

cal failure analysis (EFA) solutions for the tools required

to identify and analyze faults in their products. The new

nProber III fault localization and transistor character-

ization tool developed by FEI (Hillsboro, Ore.) provides

process development and failure analysis down to the 7

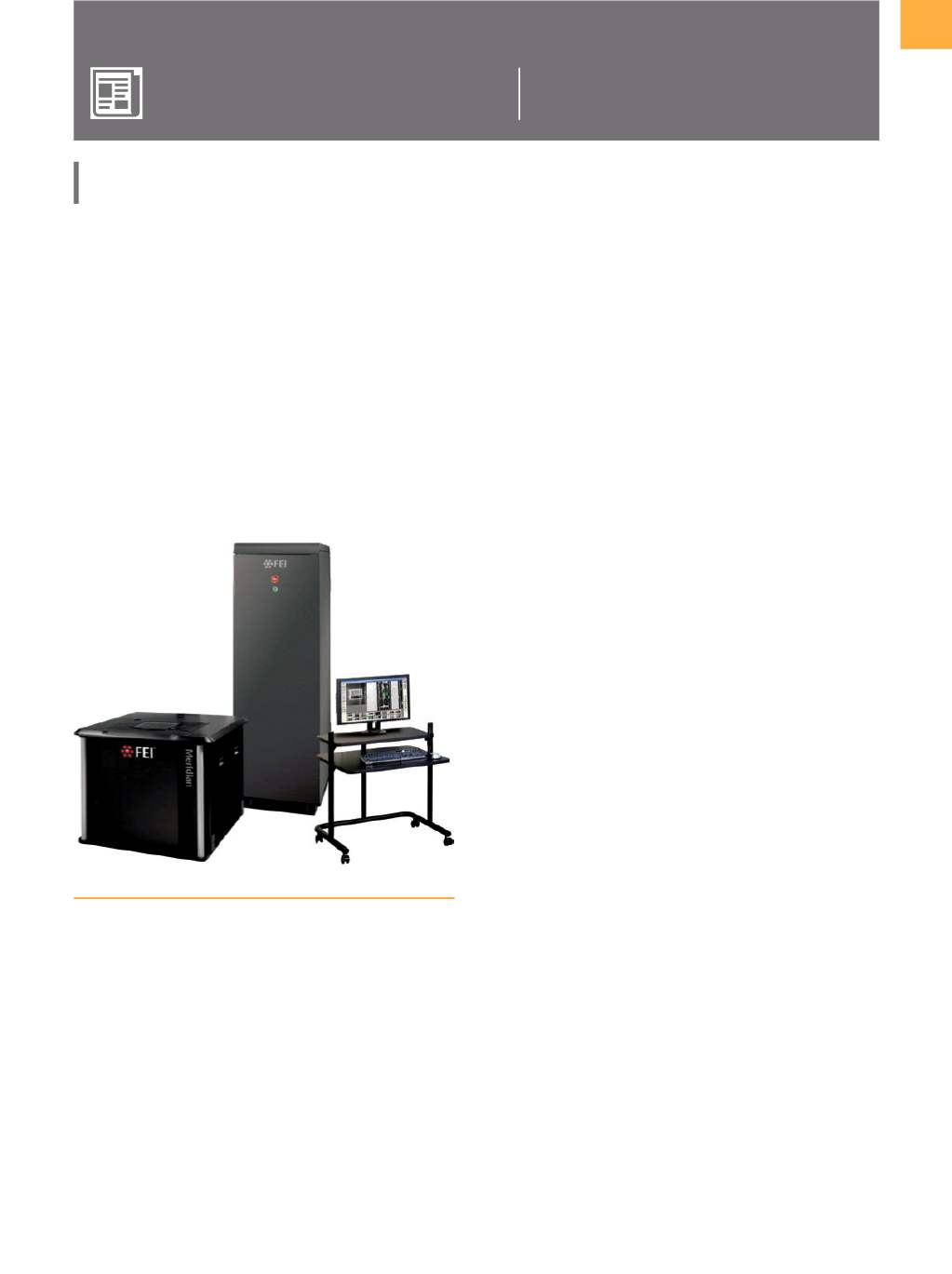

nmtechnology node. The newMeridian 7 optical fault iso-

lation tool, also developed by FEI, is designed to provide

the resolution needed for nondestructive localization of

electrical faults at sub-10-nm nodes.

extracting thin sectional samples for physical failureanaly-

sis in the TEM. In some critical applications, nanoprobing

canpotentially increase TEMsuccess rates. Designed tobe

an effective and easy-to-use tool, the nProber III doubles

the resolution and probe stability over its predecessor.

The new Meridian 7 provides visible laser voltage

imaging and probing as well as dynamic laser stimulation

on sub-10-nmdevices. By avoiding a requirement for ultra-

thin substrates, it preserves the integrity and functionality

of the device under test to provide a reliable and practical

production solution. It offers a 25% optical resolution

enhancement over the previous-generation system and

has a smaller spot size for better fault localization. In addi-

tion, thenewMeridian7offersmore certainty innavigation

and computer-aided design overlay, less cross-talk, and

higher waveform signal-to-noise over its predecessor.

For more information: web: bit.ly/2fLQZvH.

3-D NANOPRINTING IMPROVES AFM

PERFORMANCE

Tiny sensors made through nanoscale 3-D printing

may be the basis for the next generation of atomic force

microscopes (AFMs). These nanosensors can enhance the

microscopes’ sensitivity and detection speed by minia-

turizing their detection component up to 100 times. The

sensors were used in a real-world application for the first

time at École Polytechnique Fédérale de Lausanne (EPFL)

in Switzerland, and the results were published in

Nature

Communications.

The sensor ismade up of highly conduc-

tive platinum nanoparticles surrounded by an insulating

carbon matrix.

Atomic forcemicroscopy is basedonpowerful technol-

ogy that works a little like a miniature turntable. A tiny

cantilever with a nanometric tip passes over a sample

and traces its relief, atom by atom. The tip’s infinitesimal

up-and-down movements are picked up by a sensor so

that the sample’s topography can be determined. One

way to improve AFMs is to miniaturize the cantilever,

because this will reduce inertia, increase sensitivity, and

speed up detection. Researchers at EPFL’s Laboratory for

Bio- and Nano-Instrumentation achieved this by equip-

ping the cantilever with a 5-nm-thick sensor made with a

nanoscale 3-Dprinting technique. “Using ourmethod, the

FEI’s Meridian 7 optical fault isolation tool

“Automation is a high priority in our roadmap,” said

Cecelia Campochiaro, Vice President of EFA Solutions at

Thermo Fisher Scientific. “The nProber III system begins

ourmove toward automating the nanoprobing technique

by incorporating intelligent-guided operations designed

to improve time-to-results and reduce the skill required

to run the tool.”

These new solutions are part of a complete EFA

workflow that includes fault isolation, electrical probing,

delayering, sample preparation and imaging, and, when

needed, atomic-level imaging in a transmission electron

microscope (TEM). The nProber III allows FA engineers to

find and characterize individual devices preparatory to