edfas.org

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 19 NO. 1

42

cantilever can be 100 times smaller,” says Georg Fantner,

the lab’s director.

The nanometric tip’s up-and-downmovements can be

measured through the deformation of the sensor placed

at the fixed end of the cantilever. However, because the

researchers were dealing with minute movements—

smaller than an atom—they had to pull a trick out of their

hat. TogetherwithMichael Huth’s labat GoetheUniversität

at Frankfurt amMain, Germany, they developed a sensor

made up of highly conductive platinum nanoparticles

surrounded by an insulating carbonmatrix. Under normal

conditions, the carbon isolates the electrons. However,

at the nanoscale, a quantum effect comes into play:

Some electrons jump through the insulating material

and travel from one nanoparticle to the next. “It’s sort of

like if people walking on a path came up against a wall,

and only the courageous few managed to climb over it,”

said Fantner. When the shape of the sensor changes, the

nanoparticlesmove farther away fromeach other, and the

electrons jump between them less frequently. Changes in

the current thus reveal the deformation of the sensor and

the composition of the sample.

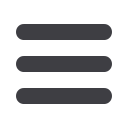

The researchers’ real feat was in finding a way to

produce these sensors in nanoscale dimensions while

carefully controlling their structure and, by extension,

their properties. “In a vacuum, we distribute a precursor

gas containing platinum and carbon atoms over a sub-

strate. Then we apply an electron beam. The platinum

atoms gather and form nanoparticles, and the carbon

atoms naturally form a matrix around them,” said Maja

Dukic, the article’s lead author. “By repeating this process,

we can build sensors with any thickness and shape we

want. We have proven that we could build these sensors

and that they work on existing infrastructures. Our tech-

nique can now be used for broader applications, ranging

from biosensors and antilock braking sensors for cars to

touch sensors on flexible membranes in prosthetics and

artificial skin.”

For more information: web: nature.com/articles/

ncomms12487.

ECONO BOARD PROBES ENHANCE

MEASUREMENTS

Econo Board probes are the first group released

from Oxford Instruments Asylum Research’s new line

of SurfRider probes. “Econo Board probes can be used

by all atomic force microscope users doing routine mea-

surements,” said Teimour Maleki, Director of MEMS and

Business Technology at AsylumResearch (Santa Barbara,

Calif.). “We’re excited to nowoffer not only an economical

probebut one that canbeused formany advancedmodes.

When you buy probes from Asylum Research, you are

assured that the industry’s best customer support team

will help you select the optimal probe for your sample

and experiment.”

Econo Board probes are available in eight different

models covering resonance frequencies ranging from 13

to 300 kHz. Econo Board probes come in PtIr-coated and

noncoated models. They are ideal for all atomic force

microscopebrands,models, andmodes, including tapping

mode, forcemodulation, contact mode, and nanoelectri-

cal and nanomechanical characterization modes.

For more information: web: oxinst.com.

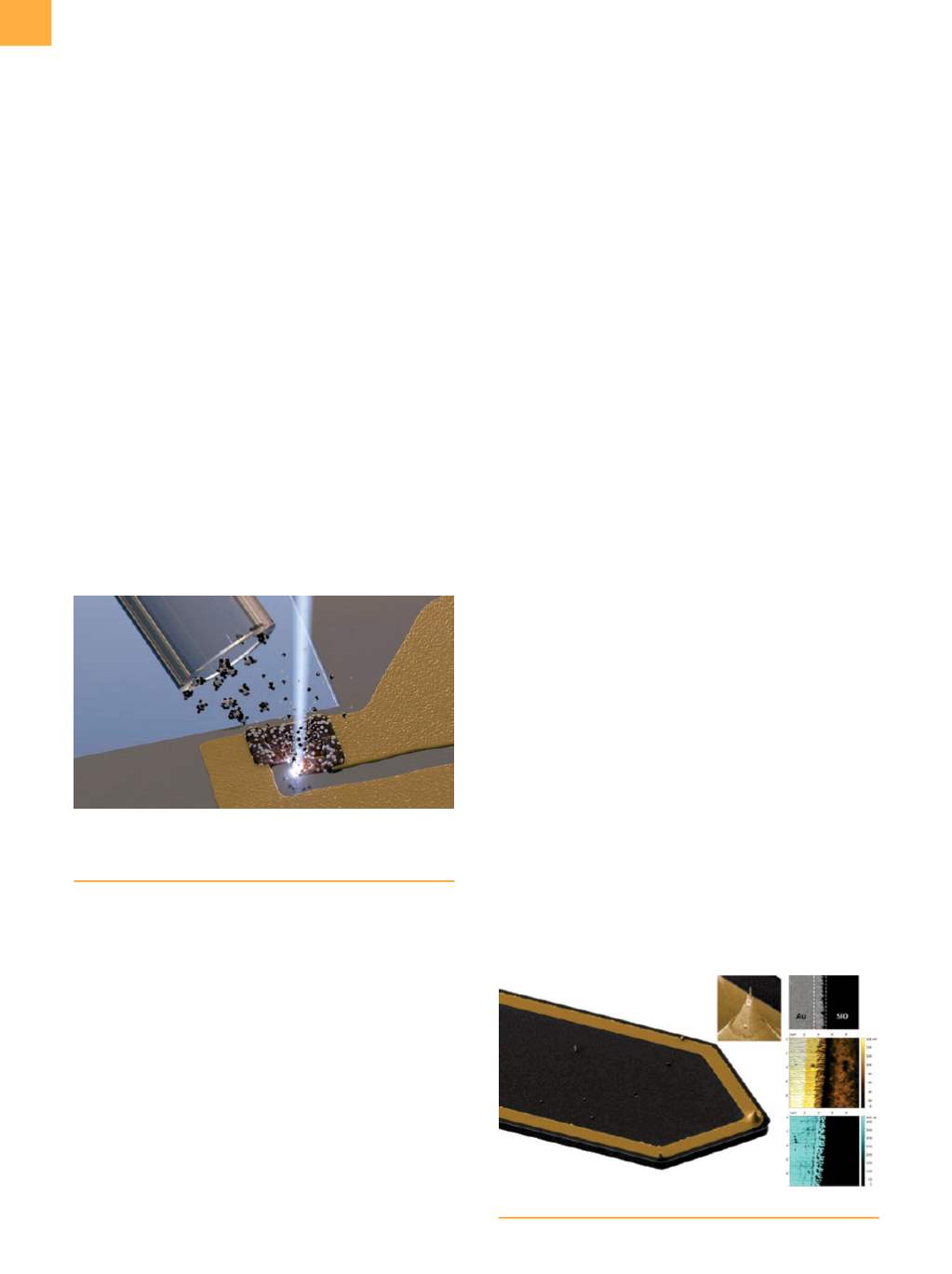

SELF-SENSING CANTILEVERS

AVAILABLE FOR AFSEM

GETec and Nanosurf (Suwon, Korea) now offer self-

sensing conductive cantilevers for the atomic force

scanning electron microscope (AFSEM) that enable con-

ductivity probing in the vacuumenvironment of the SEM.

The SEM is an established tool for imaging, processing,

andmaterials analysis of surfaces. However, it is not pos-

sible to measure local electrical properties, such as the

The sensor is made up of highly conductive platinum

nanoparticles surrounded by an insulating carbon matrix.

Source: EPFL

Self-sensing conductive cantilever with solid platinum tip