iTSSe

TSS

A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y / J U N E 2 0 1 7

4 2

iTSSe

TSS

FEATURE ARTICLE

8

F

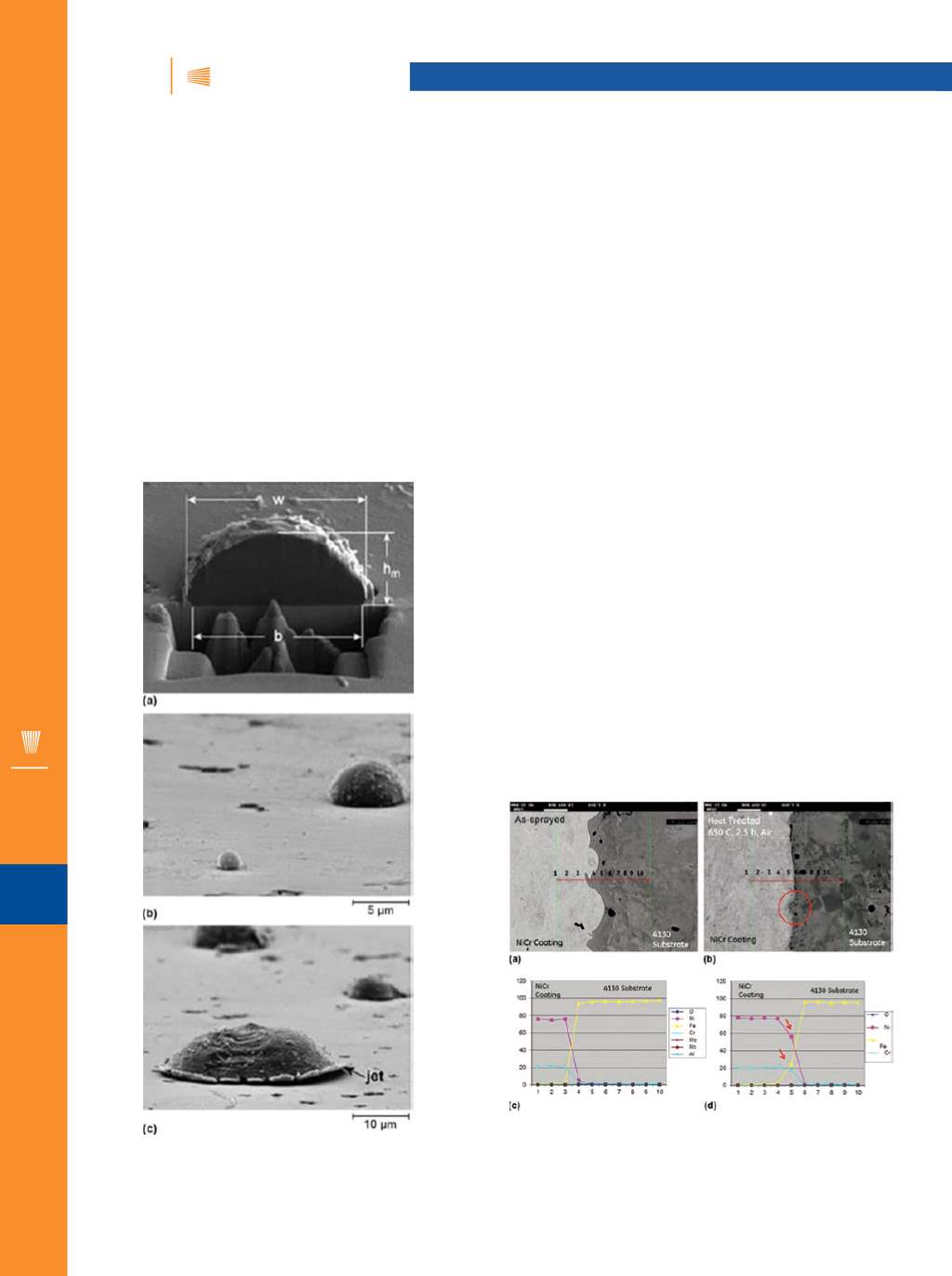

ocused ion beam (FIB) systems are selectively used in

cold spray coating characterization to gather information

on the nature of splat formation, single splats, multiple

splats, or the coating-substrate interface. FIB resembles scan-

ning electron microscopy (SEM) except that instead of using a

focused beamof electrons to raster the sample surface, it uses

a focused beam of ions (usually gallium) either to image the

sample (using low-beam currents) or to remove material by

sputtering it away (high currents).

King and Jahedi

[1]

studied the effect of particle size and

bonding for aluminum and copper particles and were able to

make use of FIB machining to prepare sample sections and

then view and analyze them by means of SEM (Fig. 1a). The

particle-flattening ratios could be determined accurately us-

ing the FIB sections and used as inputs to feed into a model.

Smaller particles were seen with a higher bow shock effect in

the gas flow and exhibited greater resistance to deformation

on impact. This result was further validated using an SE image

with a stage tilt in the SEM

!

75° to precisely estimate the base

and apex of individual particles (Fig. 1b).

COLD SPRAY: ADVANCED CHARACTERIZATION

METHODS—FOCUSED ION BEAM MACHINING

AND ELECTRON PROBE MICROANALYSIS

This article series explores the indispensable role of characterization in the

development of cold spray coatings and illustrates some of the common

processes used during coatings development.

Dheepa Srinivasan, GE Power, GE India Technology Center, Bangalore

Fig. 1

— (a) Focused ion beam/scanning electron microscopy

image of aluminumparticle dissected using Ga ions.

(b, c) Secondary electron micrographs of aluminumparticles adher-

ing to ceramic (lead-zirconium titanate) surface

[1]

.

Fig. 2

—Representative scanning electron micrographs showing

Ni-20Cr coating on AISI 4130 steel substrate interface, (a) as sprayed

and (b) aer heat treatment. (c, d) Corresponding electron probe

microanalysis elemental profiles indicating the interdi¥usion of

elements at the interface

[2]

.