EDITORIAL

iTSSe

TSS

A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y / J U N E 2 0 1 7

4 0

iTSSe

TSS

has enabled down-selecting TBCs over the past 70 years to re-

fined, specific chemistries. Thus, “fiddling with compositions”

has positive engineering and economic outcomes. However,

the critical evaluation of these methods is that society cannot

wait another 70 years to evolve future generations of TBCs and

other coatings that serve the energy sector.

LOOKING FOR THE LEAPFROG

EVENT AND PATH

Demand for energy will continue to grow and the need

for improved materials for infrastructure applications will

drive materials engineering developments for both existing

and new applications. Renewable energy platforms will also

grow. These predictions are assured and they imply opportu-

nities to grow the market for R&D in materials development.

Following are some suggested directions:

Equipment growth.

Cold spray has become a more prev-

alent and accepted TS technology over the past five years.

Applications are emergingwhere cold spray

[9]

can play a domi-

nant role in energy sectors. Aerosol deposition

[10]

is a technolo-

gy akin to flame pyrolysis and deposition. It can be adopted as

a thermal spray technology and evolve with instrumentation

and techniques used for TS. Very low-pressure plasma spray,

or VLPPS (0.75-3.75 torr compared with 37-150 torr for con-

ventional LPPS), has the capability of manufacturing unique,

oxygen-free structures, which would enhance bond coat

chemistries to moderate TGOmechanisms.

Coatings for specialized energy-harvesting applications.

Coatings are needed for fiber-reinforced polymer composites

(FRPCs), heat sensitive substrates used in wind, solar, and

photovoltaic energy-harvesting systems. A protective coating

is required not only to resist erosion from dust and sand, but

also to combat environmental pollution and corrosion. Hy-

dropower and geothermal energy plants would benefit from

coatings that resist cavitation, abrasion, and erosion. These

coatings could require customized feedstocks, which presents

opportunities for materials development

[11]

.

General infrastructure maintenance.

Corrosion control

coatings (e.g., arc-sprayed zinc and zinc-aluminum coat-

ings) provide substantial benefits for offshore and onshore

installations.

Special needs for nontraditional energy-producing sec-

tors.

Energy produced from biomass, nuclear sources, fuel

cells, and geothermal sources, as well as from an improved

hydrogen economy and waste-to-energy plants, require ma-

terials and coatings that will enhance the lifecycle economics

of producing energy. The leapfrog opportunity is to recognize

that the materials structure must be designed appropriately

for each particular energy sector, i.e., one microstructure does

not fit all applications. The age of focusing on convention-

al yttria-stabilized zirconia chemistries is coming to an end.

Generation 3, 4, and future coatings will evolve from scientif-

ic knowledge gathered over the past 20 years. The design of

the void structure, ranging from 100% density to globular and

interlamellar pores and micro and macrocracks orientated in

certain directions, controls extrinsic materials properties, and

hence the application.

SUMMARY

A previous commentary by Armelle Vardelle and Rob-

ert Vassen discussed the potential for thermal spray coatings

in energy production sectors

[12]

. “To meet the projected in-

creased demand of electricity, it is essential to improve effi-

ciencies of all energy generation processes, and this includes

the development of better materials, operation at higher tem-

peratures, improved corrosion resistance, electricity storage

capacity, and electrochemical or catalytic performance,” they

noted. “These specific materials properties are often attained

by means of advanced coatings. Here the thermal spray tech-

nology offers a variety of different processes such as plasma,

high velocity oxy fuel, or suspension spraying, which allow the

design of innovative and highly effective coatings at affordable

prices.”

~iTSSe

For more information:

Christopher C. Berndt is a Distin-

guished Professor, Swinburne University of Technology, Victo-

ria, Australia, +61 3 9214 8706,

cberndt@swin.edu.au,

www. swinburne.edu.au.

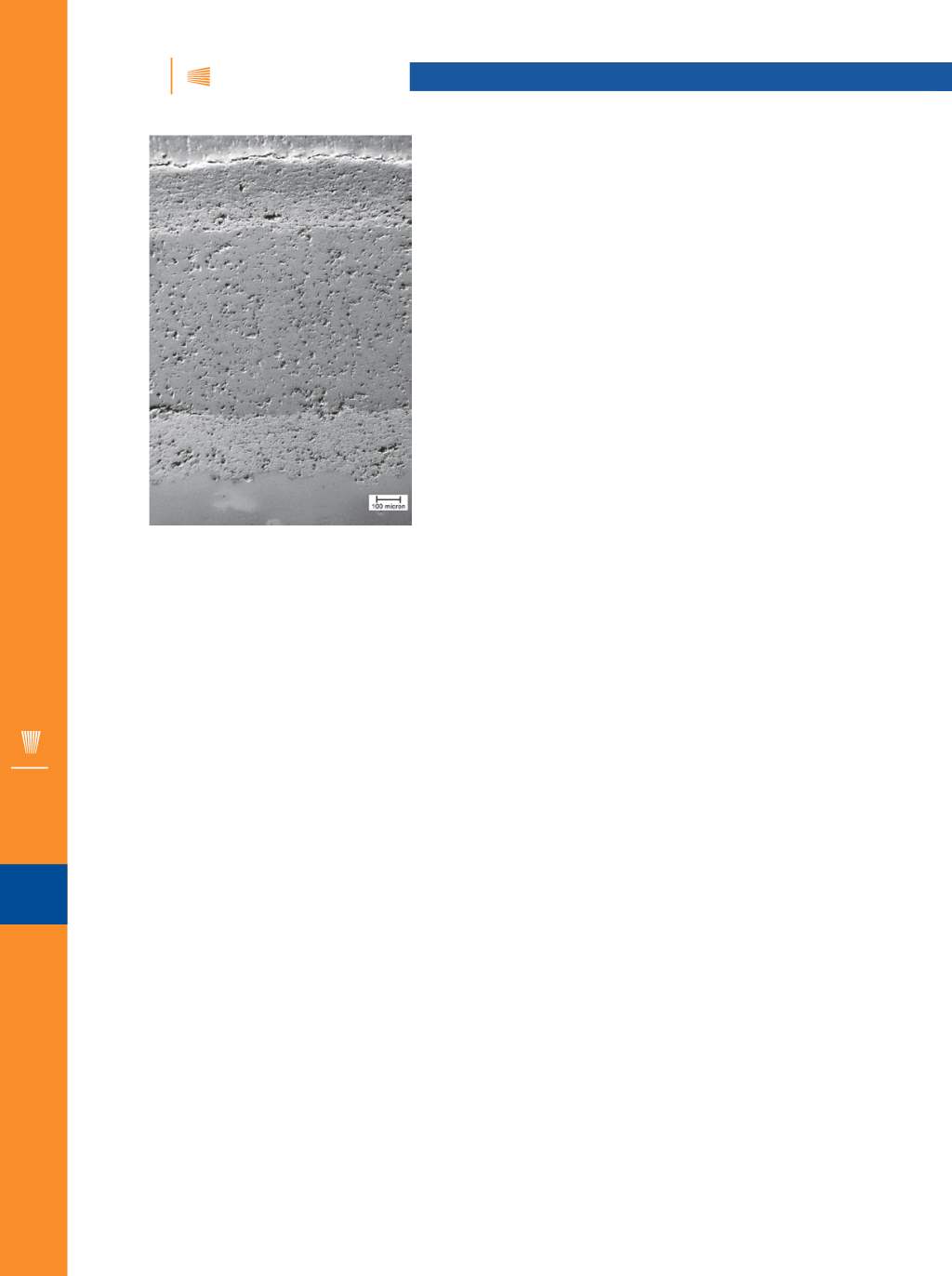

Fig. 5

—Multilayer TBC developed at Swinburne University of

Technology for a hypersonic application (unpublished data).

FEA U E ARTICLE

6