iTSSe

TSS

A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y / J U N E 2 0 1 7

4 4

iTSSe

TSS

CASE STUDY

10

REASON TO CONSIDER SURFACING

Finished surface quality is of paramount importance to

parts that are mass-produced using blowmolding and

plastic injectionmolding technologies. Wear that causes dimensional

changes in tooling (and final parts) can be greatly reduced by

applying a wear-resistant carbide, stainless steel, or ceramic

surface to tooling components via thermal spray.

Carbide ther- mal spraysurfacing is an established additive surfacing tech-

nique used in many plastic material processing applications.

New parts processed with a wear-resistant thermal spray

coating give tooling components remarkably greater service

life. During routine maintenance, worn parts often can be re-

surfaced back to OEM specifications, significantly reducing

replacement costs.

ASB Industries works with OEMs and rebuilders to pro-

tect and maintain quality tooling components to meet equip-

ment design specifications. ASB recently worked with a local

manufacturer of blowmolded and injectionmolded products.

This application is discussed here.

ISSUES

Blowmold head tooling wear was being caused by glass-

filled nylonmaterial. This tooling wear was creating die gap is-

sues, disrupting material flow during production, and causing

nonconforming parts to be manufactured.

OPTION

ASB Industries applied a commercially available tung-

sten carbide coating on the head tooling using the high

velocity oxy-fuel (HVOF) process. A coating thickness of 0.010

in. per side is applied to the die component ID and to the pin

component OD. Each component requires diamond finish

grinding to achieve the final dimensions and a surface finish

of 32 Ra micro-in.

BENEFITS

Tooling that was not coatedwith tungsten carbide began

to showwear and create die gap issues after only eightmonths

of runtime, but continued to be used in production. Worn tool-

ing was eventually replaced with newly coated components.

Tooling service life went from just eight months to more

than 23 months so far; the customer is experiencing less

downtime and labor to remove worn components.

As of this writing, the manufacturer has plans to install a

new set of nitride components due to less cost compared to

the HVOF carbide coating. Some of the engineers and mainte-

nance personnel believe a quick repair is easier than the two

or three weeks of turnaround time for coating removal, car-

bide coating, and diamond grinding. The other engineers and

maintenance personnel believe the HVOF carbide coating is a

better value. This will be an ongoing case study.

~iTSSe

For more information:

Scott Whitten is an application

specialist at ASB Industries Inc., 1031 Lambert St., Bar-

berton, OH 44203, 330.753.8458,

scott@asbindustries.com,

www.asbindustries.com.

CARBIDE THERMAL SPRAY SURFACING

PROTECTS BLOW MOLD HEAD TOOLING

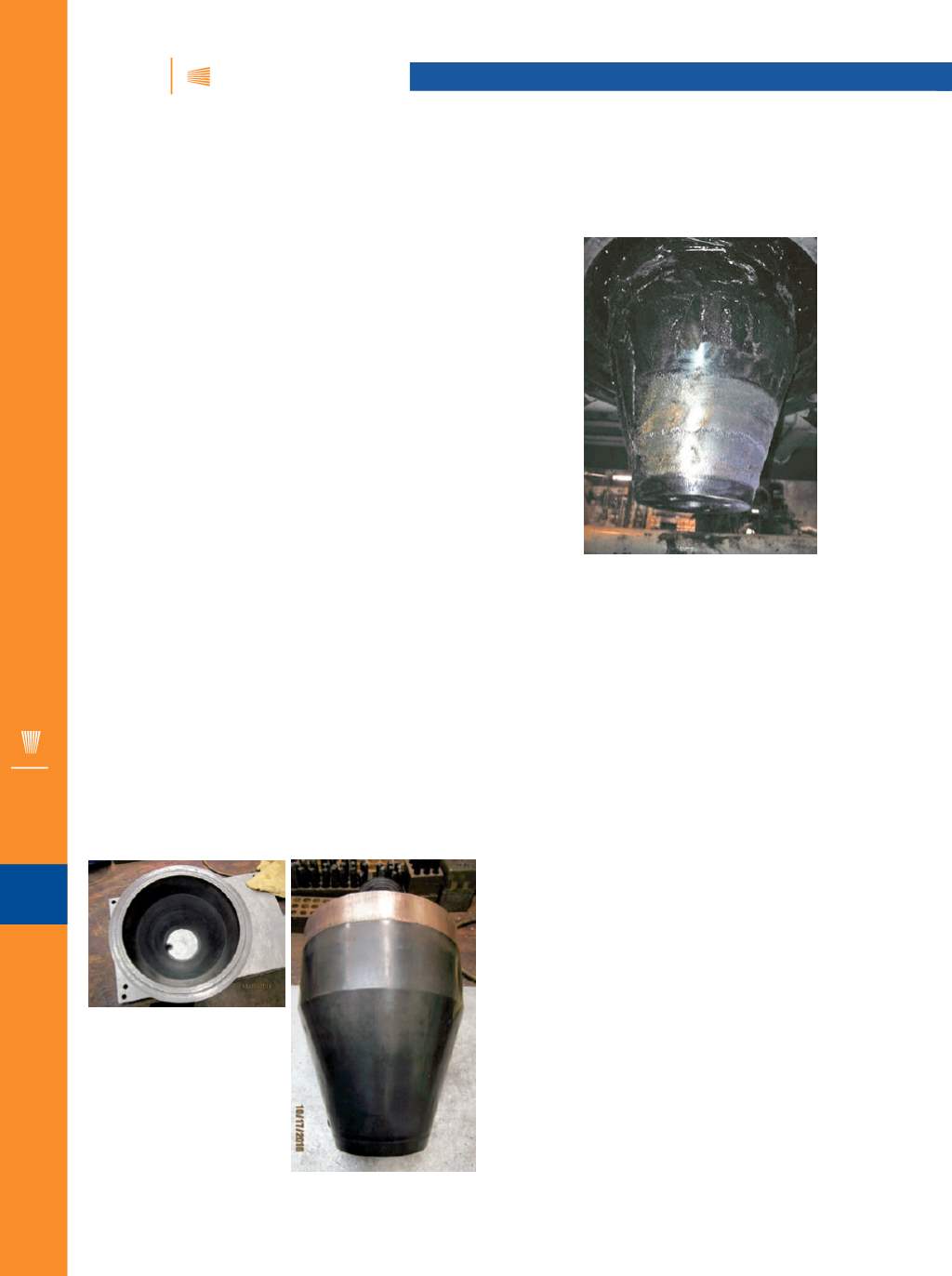

Fig. 1

– Blowmold head tooling (die and pin) coated with a tung-

sten carbide/cobalt matrix aer 19 months in service.

Fig. 2

– Non-coated blowmold head tooling (pin) aer 17 months

in service.