iTSSe

TSS

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A Y / J U N E

2 0 1 7

4 5

T

|

iTSSe

TSS

JTST

HIGHLIGHTS

11

The

Journal of Thermal Spray

Technology (JTST),

the official

journal of the ASMThermal Spray

Society, publishes contributions

on all aspects—fundamental and

practical—of thermal spray sci-

ence, including processes, feed-

stock manufacture, testing, and

characterization. As the primary

vehicle for thermal spray infor-

mation transfer, its mission is to

synergize the rapidly advancing

thermal spray industry and related industries by presenting

research and development efforts leading to advancements

in implementable engineering applications of the technolo-

gy. Articles from the February and April issues, as selected by

JTST

Editor-in-Chief Armelle Vardelle, are highlighted here.

The April issue contains a special focus on “Metal Additive

Manufacturing,” organized by guest editors Bertrand Jodoin,

Mathieu Brochu, Jean-Yves Hascoet, and Todd Palmer. The

third, fourth, and fifth articles highlighted here are from this

special focus. In addition to the print publication,

JTST

is avail-

able online through springerlink.com. For more information,

visit asminternational.org/tss.

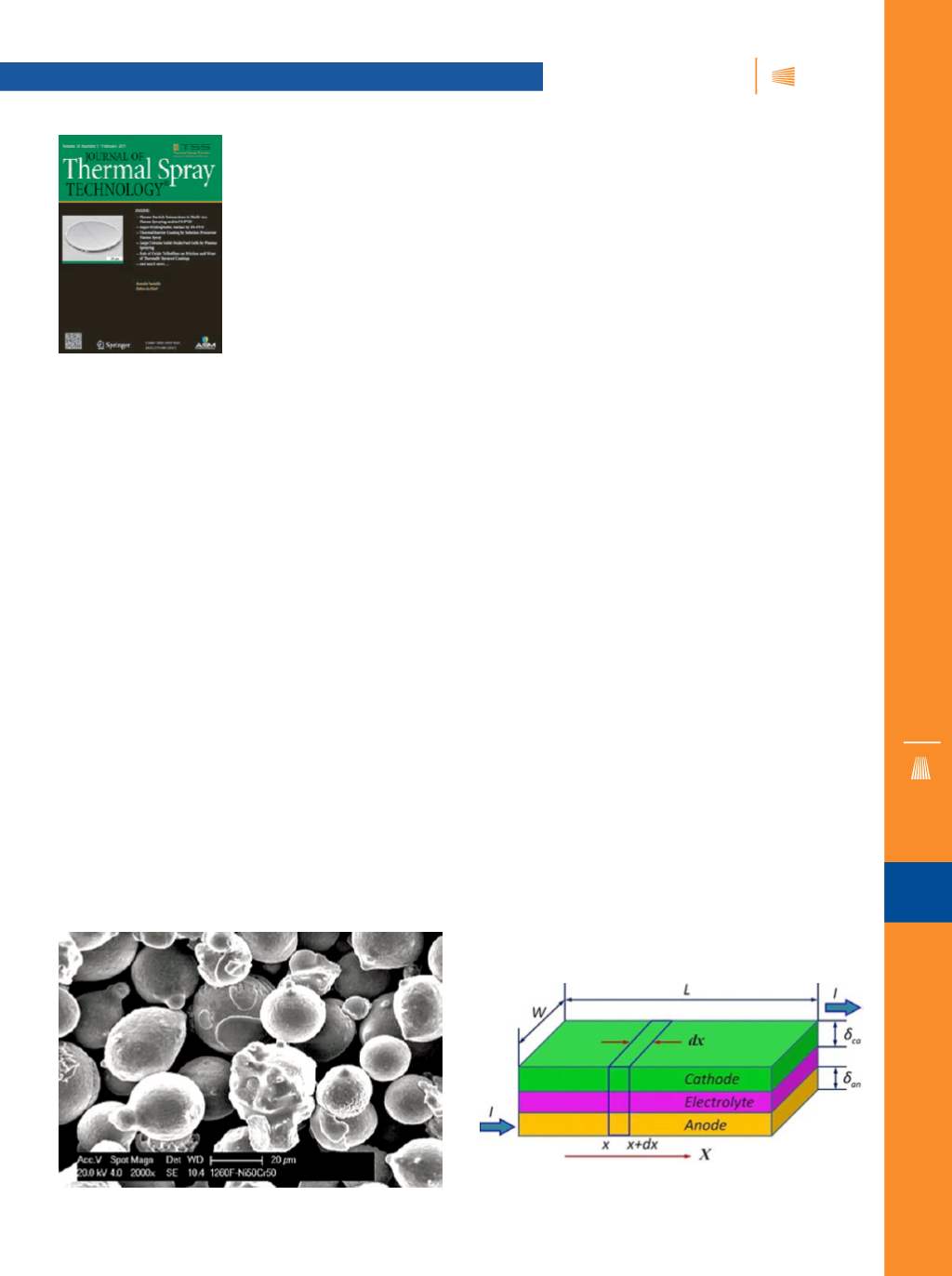

ROLE OF OXIDES AND POROSITY ON HIGH-

TEMPERATURE OXIDATION OF LIQUID-FUELED

HVOF THERMAL-SPRAYED NI50CR COATINGS

B. Song, M. Bai, K.T. Voisey, and T. Hussain

Highchromiumcontent inNi50Cr thermally sprayedcoat-

ings can generate a dense and protective scale at the coating

surface. Thus, the Ni50Cr coating is widely used in high-tem-

perature oxidation and corrosion applications. A commercial-

ly available, gas atomized Ni50Cr powder was sprayed onto

a power plant steel (ASME P92) using a liquid-fueled HVOF

thermal spray with three processing parameters in this study.

The microstructure of as-sprayed coatings was examined

using oxygen content analysis, mercury intrusion porosimetry,

scanning electron microscopy (SEM), energy-dispersive x-ray

spectroscopy (EDX), and x-ray diffraction (XRD). Short-term air

oxidation tests (4 h) of freestanding coatings (without boiler

steel substrate) in a thermogravimetric analyzer at 700°C were

performed to obtain the kinetics of oxidation of the as-sprayed

coating. Long-term air oxidation tests (100 h) of the coated

substrates were performed at the same temperature to obtain

the oxidation products for further characterization in detail

using SEM/EDX and XRD. In all samples, oxides of various mor-

phologies developed on top of the Ni50Cr coatings. Cr

2

O

3

was

themain oxidation product on the surface of all three coatings.

The coating with medium porosity and medium oxygen con-

tent had the best high-temperature oxidation performance in

this study (Fig. 1).

THERMALLY SPRAYED LARGE TUBULAR

SOLID OXIDE FUEL CELLS AND ITS STACK:

GEOMETRY OPTIMIZATION, PREPARATION,

AND PERFORMANCE

Shan-Lin Zhang, Cheng-Xin Li, Shuai Liu, Chang-Jiu Li,

Guan-Jun Yang, Peng-Jiang He, Liang-Liang Yun, Bo Song,

and Ying-Xin Xie

In this study, a large tubular solid oxide fuel cell (SOFC)

design was developed with several cells in series on a porous

cermet support with characteristics such as self-sealing, low

ohmic loss, high strength, and good thermal expansion co-

efficient matching. Aspects of the cell design, manufacture,

performance, and application are investigated. First, the cell

length and number of cells in series are optimized by theoret-

ical analysis. Thermal spray is then applied as a cost-effective

method to prepare cell components. Finally, performance of

different types of cells and two types of stacks is character-

ized. The maximum output power of one tube, which has 20

cells in series, reaches 31 W and 40.5 W at 800°C and 900°C,

respectively. Moreover, the output power of a stack assembled

with 56 tubes, each with 10 in series, reaches 800 W at 830°C.

Excellent single tube and cell stack performance suggests that

thermally sprayed tubular SOFCs have significant potential for

commercial applications (Fig. 2).

Fig. 1

− SEM image of as-received powder particle morphology.

Fig. 2

− Schematic of the current flow inside a single cell in SS-SOFC

design.