iTSSe

TSS

A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y / J U N E 2 0 1 7

4 6

iTSSe

TSS

JTST

HIGHLIGHTS

12

ADDITIVE MANUFACTURING OF ALSI

10

MG

ALLOY USING DIRECT ENERGY DEPOSITION:

MICROSTRUCTURE AND HARDNESS

CHARACTERIZATION

M. Javidani, J. Arreguin-Zavala, J. Danovitch, Y. Tian, and

M. Brochu

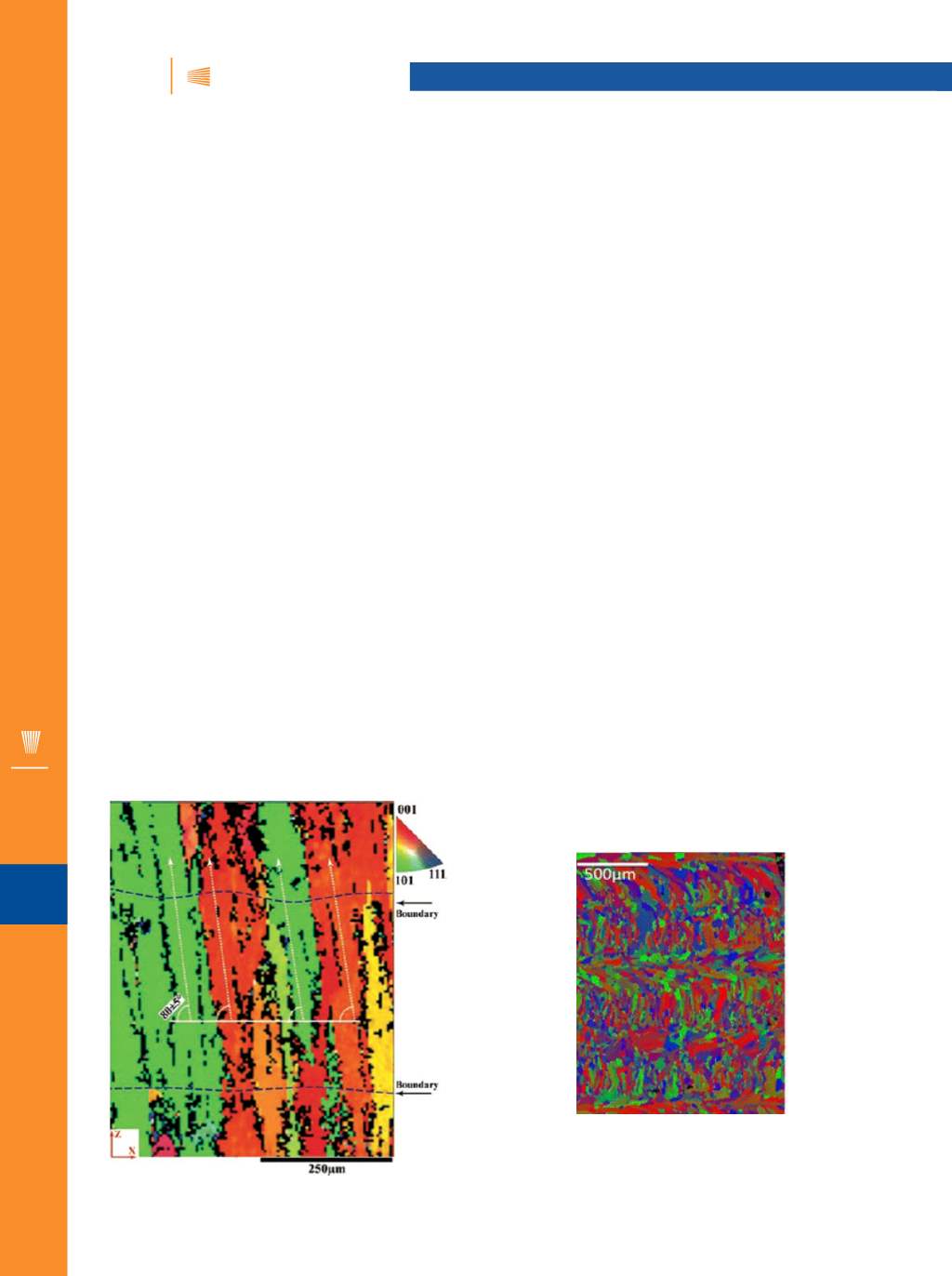

This paper aims to study AlSi

10

Mg alloy manufacturing

with the direct energy deposition (DED) process. Following

fabrication, the macro- and microstructural evolution of the

as-processed specimens were initially investigated using

optical microscopy and scanning electron microscopy. A co-

lumnar dendritic structure was the dominant solidification

feature of the deposit; nevertheless, detailed microstructural

analysis revealed cellular morphology near the substrate and

equiaxed dendrites at the top end of the deposit. Moreover,

the microstructural morphology in the melt pool boundary of

the deposit differed from the one in the core of the layers. The

remaining porosity of the deposit was evaluated by Archime-

des’ principle and by image analysis of the polished surface.

Crystallographic texture in the deposit was also assessed us-

ing electron backscatter diffraction (EBSD) and x-ray diffrac-

tion analysis. The dendrites were unidirectionally oriented at

an angle of ~80° to the substrate. EPMA line scans were per-

formed to evaluate the compositional variation and elemental

segregation in different locations. Eventually, microhardness

(HV) tests were conducted in order to study the hardness gra-

dient in the as-DED-processed specimen along the deposition

direction. The results, which exhibit a deposit with an almost

defect-free structure, indicate that the DED process is suitable

for the deposition of Al-Si-base alloys with a highly consolidat-

ed structure (Fig. 3).

PROCESS-STRUCTURE-PROPERTY

RELATIONSHIPS FOR 316L STAINLESS STEEL

FABRICATED BY ADDITIVE MANUFACTURING

AND ITS IMPLICATION FOR COMPONENT

ENGINEERING

N. Yang, J. Yee, B. Zheng, K. Gaiser, T. Reynolds, L. Clemon,

W.Y. Lu, J.M. Schoenung, and E.J. Lavernia

This study investigates the process-structure-property

relationships for 316L stainless steel prototyping utilizing 3D

laser engineered net shaping (LENS), a commercial direct en-

ergy deposition additive manufacturing process. The study

concludes that the resultant physical metallurgy of 3D LENS

316L prototypes is dictated by interactive metallurgical reac-

tions during instantaneous powder feeding/melting, molten

metal flow, and liquid metal solidification. The study also

shows that 3D LENSmanufacturing is capable of building high

strength and ductile 316L prototypes due to its fine cellular

spacing from fast solidification cooling, and well-fused epi-

taxial interfaces at metal flow trails and interpass boundaries.

However, without further LENS process control and optimiza-

tion, deposits are vulnerable to localized hardness variation

attributed to heterogeneous microstructure, i.e., the inter-

pass heat-affected zone (HAZ) from repetitive thermal heating

during successive layer depositions. Most significantly, current

deposits exhibit anisotropic tensile behavior, i.e., lower strain

and/or premature interpass delamination parallel to build di-

rection (axial). This anisotropic behavior is attributed to the

presence of interpass HAZ, which coexists with flying feed-

stock inclusions and porosity from incomplete molten metal

fusion. The current observations and findings contribute to

the scientific basis for future process control and optimization

necessary for material property control and defect mitigation

(Fig. 4).

Fig. 3

− EBSDmapping at middle (half height) of specimen; inverse

pole figure (IPF) colored orientation image map, with IPF.

Fig. 4

− Morphology, size, and crystal orientation for the solidifica-

tion cells: EBSD orientation map.