iTSSe

TSS

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A Y / J U N E

2 0 1 7

4 7

T

I

|

iTSSe

TSS

JTST

HIGHLIGHTS

13

COLD SPRAYING OF ARMSTRONG PROCESS

TITANIUM POWDER FOR ADDITIVE

MANUFACTURING

D. MacDonald, R. Fernández, F. Delloro, and B. Jodoin

Titanium parts are ideally suited for aerospace applica-

tions due to their unique combination of high specific strength

andexcellent corrosion resistance. However, titaniumbulkma-

terial is expensive and challenging to machine. Production of

complex titanium parts through additive manufacturing looks

promising, but there are still many barriers to overcome before

reachingmainstreamcommercialization. The cold gas dynam-

ic spraying process has potential for additivemanufacturing of

large titanium parts due to its reduced reactive environment,

simple operation, and high deposition rates. However, a few

challenges must first be addressed. In particular, it is known

that titanium is easy to deposit by cold gas dynamic spraying,

but the deposits are usually porous when nitrogen is used as

the carrier gas. In this work, a method tomanufacture low-po-

rosity titanium components at high deposition efficiencies is

revealed. Components are produced by combining low-pres-

sure cold spray using nitrogen as the carrier gas with low-cost

titanium powder produced using the Armstrong process. The

microstructure andmechanical properties of additivelymanu-

factured titanium components are investigated (Fig. 5).

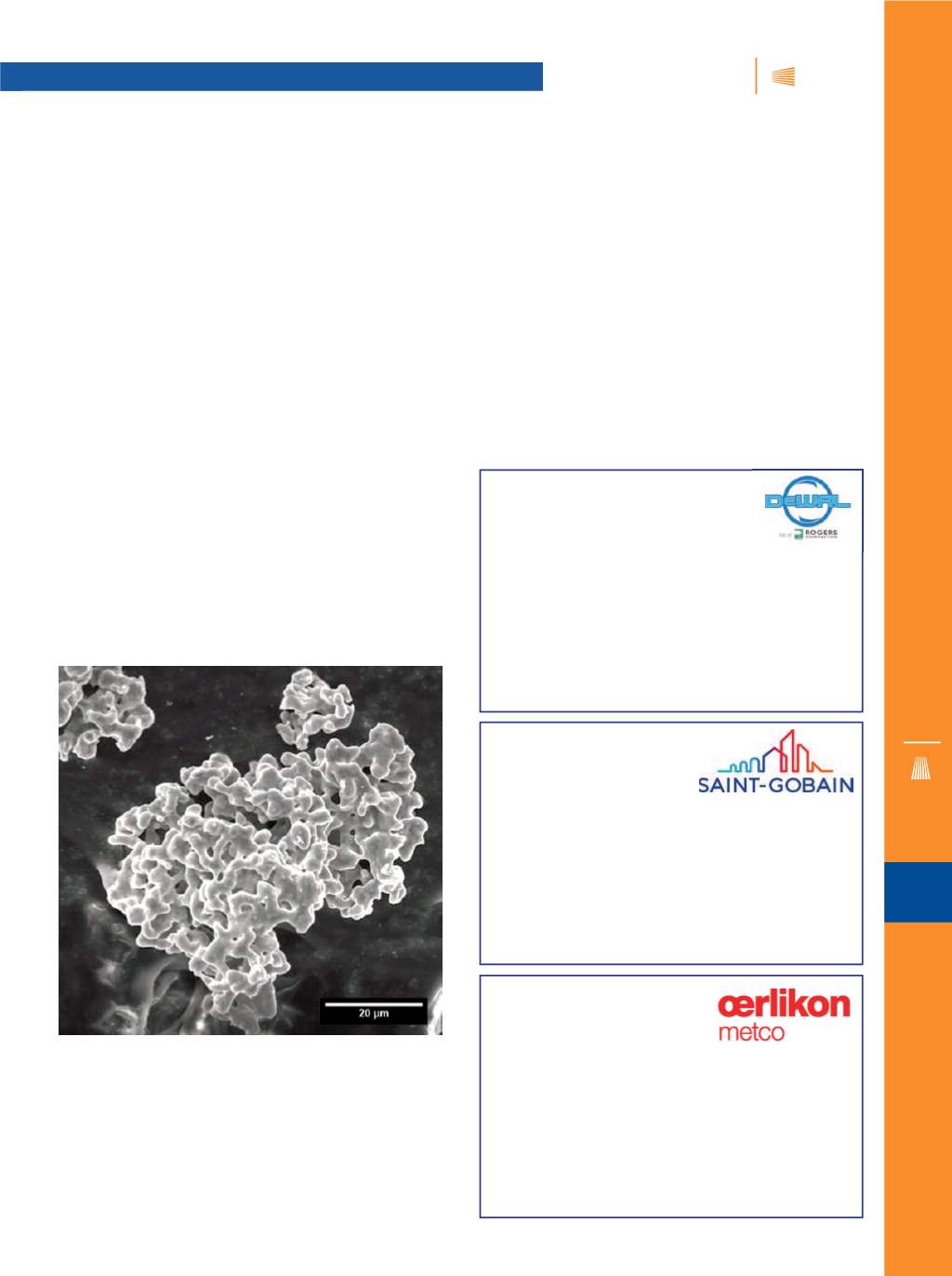

Fig. 5

− SEM image of coral-shaped titaniumpowder produced

using the Armstrong process.

2017 ITSC EXHIBITOR

SHOWCASE

VISIT THESE KEY EXHIBITORS AND

MORE AT ITSC 2017

EXHIBITIONHOURS

CCD Congress Center Düsseldorf, Stadthalle

Wednesday, June 7 • noon to 6:00 p.m.

Thursday, June 8 • 9:00 a.m. to 6:00 p.m.

Friday, June 9 • 9:00 a.m. to 4:00 p.m.

DeWAL manufactures the world’s most

complete line of thermal spray tapes.

After years developing and improving these preci-

sion plasma tapes, DeWAL manufactures them in Rhode

Island for aircraft engine, automotive and medical manufacturers. DeWAL tapes

are used by all three major aircraft engine manufacturers—GE, Pratt & Whitney,

and Rolls-Royce.

DeWAL tapes are free of carbonizingmaterials for grit blast, ceramic, plas-

ma, arc, and HVOF spraying. Whatever temperature or spray angle, they adhere

aggressively, ensuring sharp edges, then separate cleanly.

Single and double-ply tapes, all manufactured with proprietary silicone

adhesive technology, are available worldwide.

www.dewal.comBooth D14

DEWAL THERMAL SPRAY TAPES

DeWAL is part of Rogers Corp

Saint-Gobain is a world class manufacturer

of equipment and consumables for the

thermal spray coatings industry. Our expansive equipment experience dates

back to 1920 with the development of the first oxy-acteylene flame wire gun

followed by Rokide® Spray Systems, Plasma Spray Systems, PTA andmany in-

novative materials. We offer a wide range of consumables in the form of powder,

flexible cords, Rokide® rods, and ingots for use in many different applications

and industries. We supply our own rawmaterials and this enables us to develop

a product to meet your exact needs.

www.coatingsolutions.saint-gobain.com.

Booth D3

SAINT-GOBAIN

COATING SOLUTIONS

Oerlikon Metco enhances surfaces that bring

benefits to customers through a uniquely broad

range of surface technologies, equipment,

materials, services, specializedmachining

services and components. The surface technologies such as Thermal Spray and

Laser Cladding improve the performance and increase efficiency and reliability.

As an innovation leader, Oerlikon Metco is forging new paths with materials for

additive manufacturing, brazing, conductive fillers, powder injectionmolding,

plasma transferred arc weld hardfacing and other industrial processes.

Oerlikon Metco serves industries such as aviation, power generation, automo-

tive, oil & gas, industrial and other specializedmarkets and operates a dynami-

cally growing network of more than 40 sites in EMEA, Americas and Asia Pacific.

Oerlikon Metco, together with Oerlikon Balzers, belongs to the Surface Solutions

Segment of the Switzerland-based Oerlikon Group.

Booth B4

OERLIKONMETCO