A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J A N U A R Y

2 0 1 7

2 1

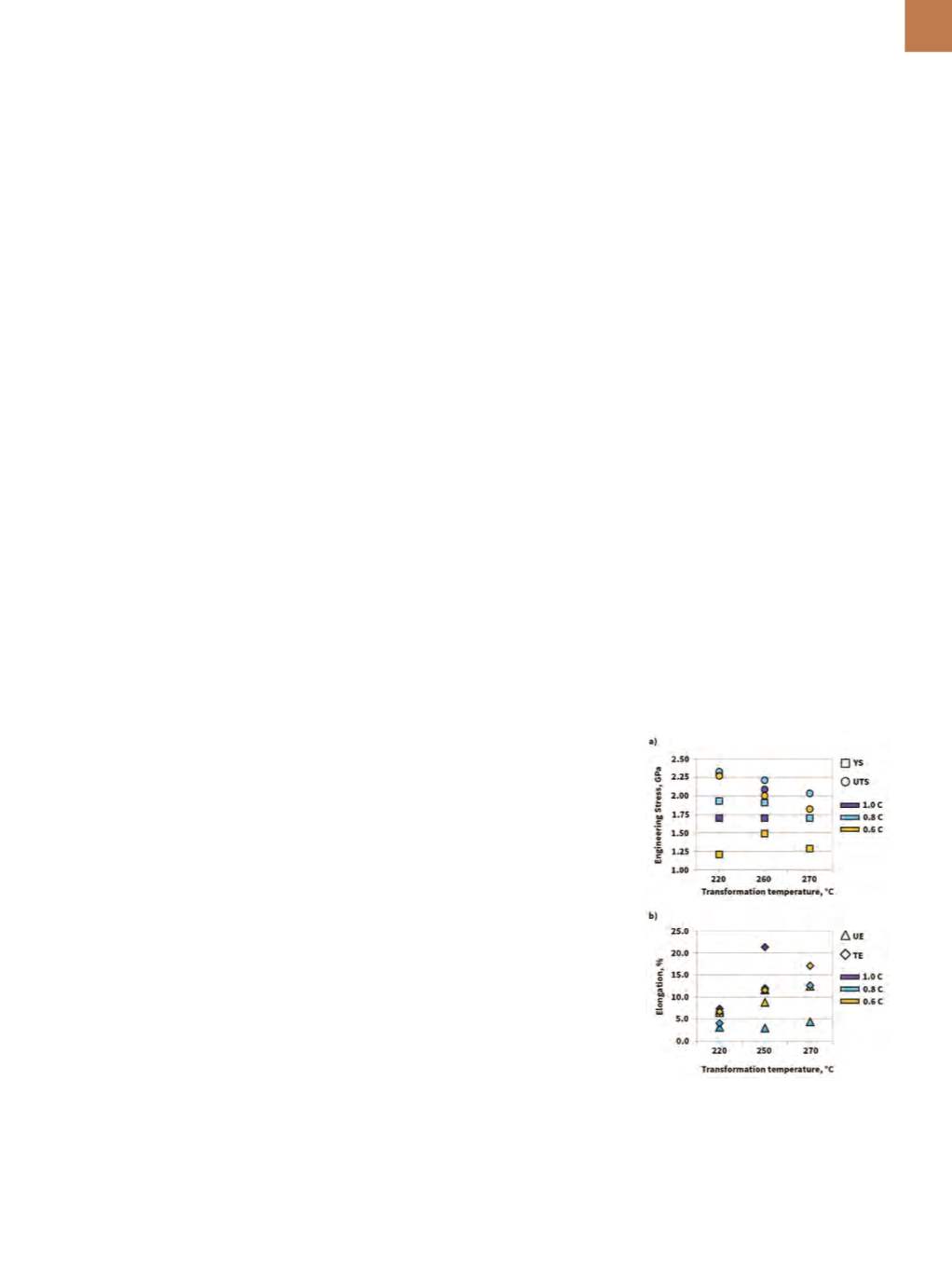

TENSILE PROPERTIES

Low-temperature transformation

bainite is harder than previously ach-

ieved, with values in excess of 700 HV.

Selected alloy compositions along with

transformation conditions and micro-

structural parameters of second-gen-

eration nanostructured bainitic steels

are shown in Table 1. After transfor-

mation at 220° and 250°C, hardness

values are always over 600 HV30 with

a bainitic ferrite plate thickness of

30-40 nm. Corresponding strength and

ductility data of the selected micro-

structures, in terms of yield strength

(YS), ultimate tensile strength (UTS),

uniform elongation (UE), and total elon-

gation (TE) are illustrated in Fig. 1.

A

nanostructured

bainite

has

been developed by heat treating

high-carbon, high-silicon steels.

The new material is being produced in

bulk and affordably without using severe

deformation or complex heat treatments.

The bainitic structures consist of nano-

scale ferrite crystals 20-60 nm thick

interwoven by austenite. Nanostruc-

tured bainite has one of the highest

known densities of ferrite/austenite

interfaces. The material has the highest

strength/toughness combination ever

recorded in bainitic steels (~2.2 GPa/40

MPa·m

1/2

)

[1]

and has extraordinary roll-

ing-sliding wear performance

[2]

. This

article discusses the characteristics and

significance of nanostructured bainite in

terms of the transformationmechanism.

HEAT TREATMENT AND

TRANSFORMATION KINETICS

Generally, lowtransformation tem-

peratures lead to fine-grained micro-

structures that have both strength and

toughness. First-generation nanostruc-

tured bainitic steels were designed us-

ing models based on the atomic mech-

anism of displacive transformation

theory

[3]

. The bainite start temperature

(B

s

)—the highest temperature at which

bainite can be formed—was lowered

mainly due to high carbon concentra-

tions. In addition, the alloys contained

enough silicon to suppress cementite

precipitation from austenite. Cementite

is a splitting and void-initiating phase,

best eliminated from strong steels. The

tradeoff to achieve the nanoscale in

these bainitic steels is extremely long

transformation times. For instance,

the bainite reaction in first-generation

nanocrystalline bainitic steels took up

to 90 days at a transformation tempera-

ture of 125°C

[3]

. However, rapid heat

treatment may be required on a com-

mercial basis.

Alloy composition can be tailored

to increase the magnitude of free ener-

gy change that accompanies austenite

decomposition (ΔG

γα

= G

α

− G

γ

), where

G

α

is the Gibbs free energy of ferrite and

G

γ

is the Gibbs free energy of austen-

ite; thus accelerating both nucleation

and growth rates. Theoretical design

in second-generation nanostructured

bainite led to processing times of hours

as opposed to days by reducing carbon,

manganese, chromium, and molybde-

num contents and by refining the pri-

or austenite grain size with the help of

niobium additions

[2]

. However, the ef-

fect of the prior austenite grain size on

bainite kinetics appears to accelerate

the reaction through coarse prior aus-

tenite grains

[4]

. Coarse austenite grains

increase growth rate and decrease nu-

cleation sites of bainitic transformation.

Growth rate is more important than nu-

cleation, so the overall outcome was ac-

celeration of the bainite reaction.

The latest research into accelerat-

ing the bainite reaction suggests partial

martensite transformation with subse-

quent transformation upon up-heat-

ing

[5]

. Though the quenching and bain-

ite transformation process occurs more

quickly than in direct isothermal trans-

formation, industrial production lines

are not yet prepared for this kind of heat

treatment.

DEVELOPING NANOSTRUCTURED METAL

AT THE ATOMIC ANDNANO SCALES

Affordable bulk production of a newly developed nanostructured bainitic steel is

possible without using severe deformation or complex heat treatments.

Rosalia Rementeria, Francisca G. Caballero , Lucia Morales-Rivas, and Carlos Garcia-Mateo

Fig. 1

—

Tensile properties on select grades

and transformation conditions.