1 6

LASER ANNEALING ENABLES

ULTRATHIN NANOMATERIALS

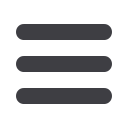

Researchers at the Institute for

Basic Science, together with a team

at KAIST, both in South Korea, discov-

ered a graphene synthesis mechanism

using laser-induced solid state phase

separation of single-crystal silicon car-

bide (SiC). Their research clarifies how

this laser technology can separate a

complex compound (SiC) into its ultra-

thin elements. Using high resolution

microscope images and molecular dy-

namic simulations, scientists found

that a single-pulse irradiation of xenon

chloride excimer laser of 30 ns melts

SiC, separating a liquid SiC layer, a dis-

ordered carbon layer with graphitic

domains (about 2.5 nm thick) on the

top surface, and a polycrystalline sil-

icon layer (about 5 nm) below the car-

bon layer. Additional pulses cause the

sublimation of the separated silicon,

while the disordered carbon layer is

transformed into multilayer graphene.

www.ibs.re.kr/eng.do,kaist.edu.

WATCH NEW CERAMIC NANO-

TECHNOLOGY IN ACTION

A new watch from Bausele Aus-

tralia uses an innovative material called

Bauselite developed in partnership with

Flinders University’s Centre of NanoScale

Science and Technology, Australia. The

advanced ceramic nanotechnology is

featured in the company’s Terra Australis

watch. Apart from the face, the case is the

most prominent featureonawatchhead—

so it needs to be visually appealing but

also lightweight and strong, says company

founder Sydneysider Christophe Hoppe.

Using a new technique, the teamcreated a

ceramic-likematerial that canbeproduced

in small batches via a non-casting pro-

cess, which helps eliminate defects found

in conventional ceramics. “Bauselite is

strong, very light and, because of the way

it is made, avoids many traps common in

conventional ceramics,” explains Hoppe.

The new material also allows holes to be

drilled more precisely. “It means we can

make bolder, more adventurous designs,”

he adds.

bausele.com.

After just one 30-ns laser pulse, an SiC substrate is melted and separates into a carbon

and a silicon layer. Courtesy of IBS.

2DMATERIALS ENHANCE

ELECTRONIC DEVICES

A new study by an international

team of researchers led by the Universi-

ty of Minnesota, St. Paul, highlights how

manipulating 2D materials could make

modern day devices faster, smaller, and

more efficient. Researchers examined

the optical properties of dozens of 2D

materials to unify understanding of

light-matter interactions and explore

possibilities for future research. They

found that polaritons—a class of quasi-

particles formed through the coupling

of photons with electric charge dipoles

in solid—allow the marriage of photon

light particle speed with the small size

of electrons. “With our devices, we want

speed, efficiency, and we want small.

Polaritons could offer the answer,” says

Tony Low, assistant professor of elec-

trical and computer engineering. By

exciting the polaritons in 2D materials,

electromagnetic energy can be focused

down to a volume a million times small-

er compared to when it is propagating

in free space.

“Layered 2D materials have

emerged as a fantastic toolbox for

nanophotonics

and

nanooptoelec-

tronics, providing tailored design and

tunability for properties that are not

possible to realize with conventional

materials,” explains Low.

For more in-

formation: Tony Low,

tlow@umn.edu,

twin-cities.umn.edu.

NANOTECHNOLOGY

Each timepiece features red earth from

the Outback, beach sand, or opal—

allowing wearers to take a piece of

Australia with themwherever they go.

2Dmaterials allow strong light-matter

interactions through polaritons.

A D V A N C E D M A T E R I A L S & P R O C E S S E S | J A N U A R Y 2 0 1 7