A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J A N U A R Y

2 0 1 7

1 3

Transforming rutile sand to titanium

aerospace components involves three

steps: Ti powder production from sand,

field assisted sintering, and forging.

Courtesy of University of Sheffield.

TITANIUM PRODUCTION

FORGES AHEAD

In collaboration with industry

partners, engineers at the University

of Sheffield, UK, are developing a new

production process for aerospace grade

titanium alloys. Dubbed FAST-forge, the

process involves the transformation of

rutile sand to novel titanium alloy aero-

space components in three steps—pro-

duction of titanium powder from rutile

sand, field assisted sintering technol-

ogy, and a one-step forging process.

FAST-forge promises increased design

flexibility and, potentially, improved

buy-to-fly ratios—a boon in an industry

where the manufacture of some com-

ponents sees 90% of forged titanium

alloy machined away to waste.

Because titanium is compatible

with carbon, it is used for fasteners and

high-strength forgings in many civilian

aircraft, which are increasingly man-

ufactured from carbon composite fu-

selage and wing structures. Orders for

these aircraft are forecast to rise over

the next decade due to increased air

travel, but with titanium’s current world

mill production capacity at approxi-

mately 130,000 tons, supply may not be

able to meet increasing demand unless

additional sources are made available.

“Titanium is a lightweight and inherent-

ly corrosion resistant material, giving it

performance, environmental, and cost

advantages over high grade steels,”

says Martin Jackson, director of aero-

space engineering and co-director of

the Sheffield Titanium Alloy Research

Group. “But it is three times the cost

of steel, with limited supply. The FAST-

forge process shows how the benefits

of titanium over steel can be achieved

more efficiently and at lower cost.”

www.sheffield.ac.uk.

BOOSTING EFFICIENCY IN

MMC MANUFACTURE

The Detroit-based public-private

consortium, Lightweight Innovations

for Tomorrow (LIFT), and Materion

Corp., Mayfield Heights, Ohio, are join-

ing forces to identify new efficiencies in

the manufacture of lightweight alumi-

num metal matrix composites (MMCs)

for transportation components. Their

two-year collaboration with indus-

try experts and university researchers

will examine the consolidation and

metalworking methods necessary to

fabricate mechanically alloyed MMCs

derived from powder metal for use in

large-scale automotive and aerospace

platforms. The team will explore alter-

natives to hot isostatic pressing (HIP),

which they believe will reduce produc-

tion time and costs while maintaining

high standards for specific modulus and

strength-to-weight ratio. Among oth-

er goals, the initiative will investigate

several product forms, including extru-

sions, 3D near-net-shape HIP, press and

sinter parts, and thin sheet.

The project team also includes

Boeing, Lockheed Martin, GKN, Case

Western Reserve University, Pennsyl-

vania State University, University of

Tennessee, Massachusetts Institute of

Technology, and Oak Ridge National

Laboratory. The group aims to render

MMCs with greater commercially viabili-

ty than current versions, for application

inautomotive, industrial, andaerospace

products in the short termand addition-

al transportationplatforms in the future.

www.lift.technology, materion.com.

PROCESS TECHNOLOGY

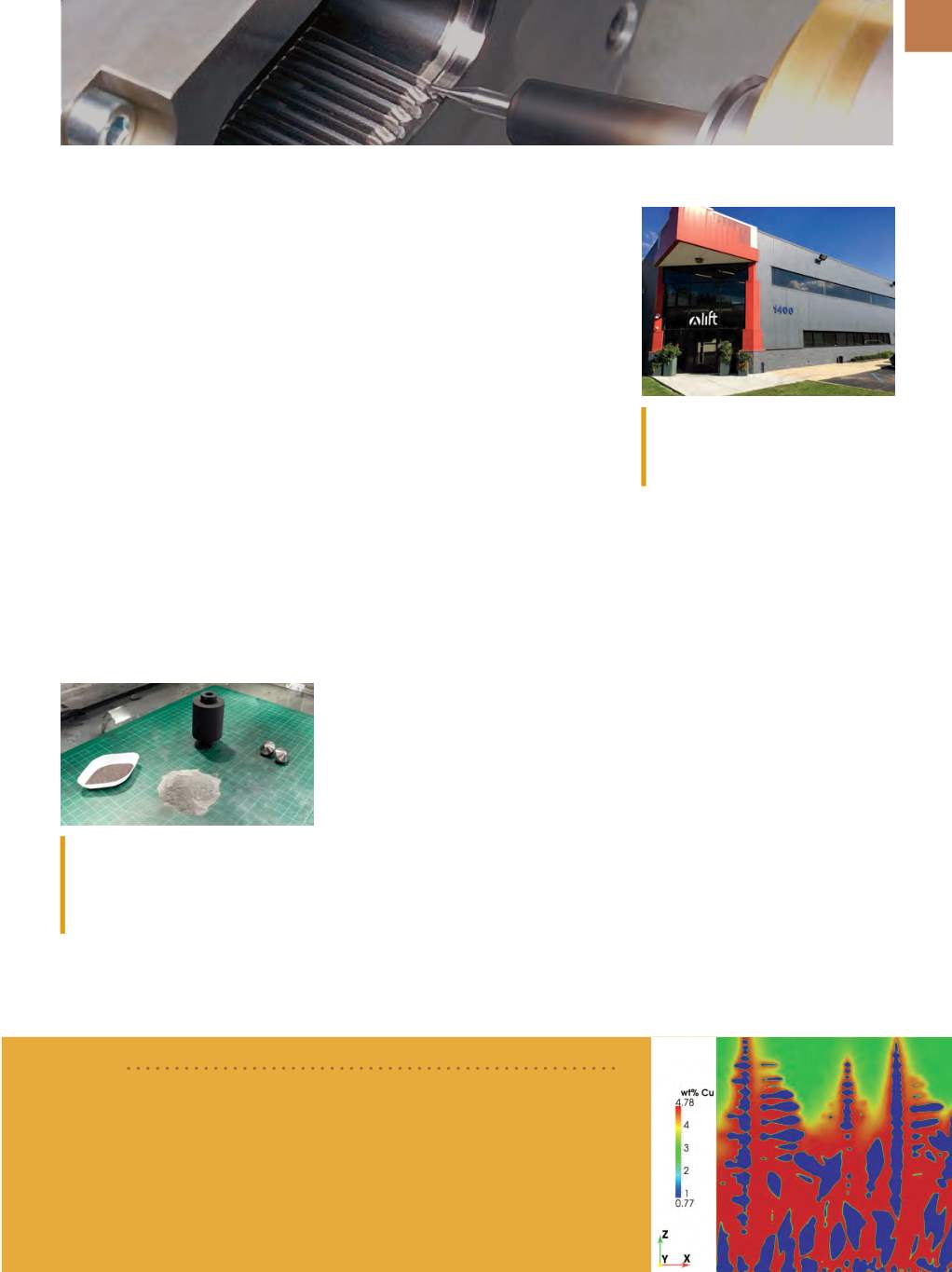

LIFT is a public-private partnership that

aims to develop and deploy advanced

lightweight materials manufacturing

technologies.

Copper distribution around dendritic microstructures during

solidification of an Al-Cu alloy. Courtesy of Mohsen Eshraghi.

NASA,

Washington, awarded

California State University,

Los Angeles two grants

totaling $840,000 to conduct materials science experiments with the International

Space Station. The project will use simulation to examine how materials solidify under

different circumstances—in space, in the absence of gravity, and on earth where gravity

is present

. nasa.gov,calstatela.edu.

BRIEF