A D V A N C E D M A T E R I A L S & P R O C E S S E S | J A N U A R Y 2 0 1 7

1 4

SURFACE ENGINEERING

NEW COATINGS PROTECT

PIPE INTERIORS

Axalta Coating Systems, Houston,

recently developed two new high tem-

perature, corrosion-resistant internal

pipe coatings. Nap-Gard 7-0017HT and

7-0017VHT Black Beauty FBE products

are thermosetting epoxy powders de-

signed to provide excellent chemical

resistance when operating in tempera-

tures to 200°C (392°F).

Corrosion caused by carbon diox-

ide and hydrogen sulphide, often found

in sour crude oil, is a major challenge

for the oil and gas industry. These high

glass transition temperature, internal

pipe coatings are designed to combat

this problem. When properly applied

with Nap-Gard 7-1808 primer, the new

coatings exhibit extreme corrosion pro-

tection against high levels of H

2

S, CO

2

,

and methane, even at elevated tem-

peratures and pressures.

axaltacs.com.

CHEMICAL VAPOR DEPOSITION

PRODUCES BIODEGRADABLE

POLYMERS

Researchers from the University

of Michigan, Ann Arbor, Northwestern

Polytechnical University, China, and

the Karlsruhe Institute of Technology,

Germany, introduced the first chemi-

cal vapor deposition (CVD) method to

produce degradable polymers. Biomol-

ecules or drugs can be attached using

special side groups, which allows coat-

ing of biodegradable implants.

The achievement was made using

two special types of monomers—the

BRIEF

MetaSOL nanotechnology coatings from

MetaShield LLC

, N.Y., provide a 1.2% (absolute) efficiency boost for triple junction solar

cells, according to an independent research study. The material is a nanoparticle embedded, glass-based coating that increases

efficiency using advanced light trapping technology. The formula is sprayed directly onto a solar cell’s existing antireflective coating

and hardens at room temperature, forming a transparent ~200 nm glass film.

metashield.com.paracyclophanes usually used for this

process were combined with cyclic ke-

tene acetals. While classic polymers

based on paracyclophanes are con-

nected exclusively through carbon-car-

bon bonds, the ketene acetal converts

during polymerization so that ester

bonds are formed within the polymer

backbone. Such bonds can be broken in

aqueous environments.

“The speed of degradation de-

pends on the ratio of the two types of

monomers as well as their side chains,”

explains lead researcher Jörg Lahann.

“Polar side chains make the polymer

film less hydrophobic and accelerate

degradation because water can pene-

trate more easily. The speed of degra-

dation can thus be tailored to the in-

tended use.” Tests show that neither the

polymer nor its degradation products

are toxic.

For more information: Jörg Lah-

ann,

lahann@umich.edu,

www.umich.edu.

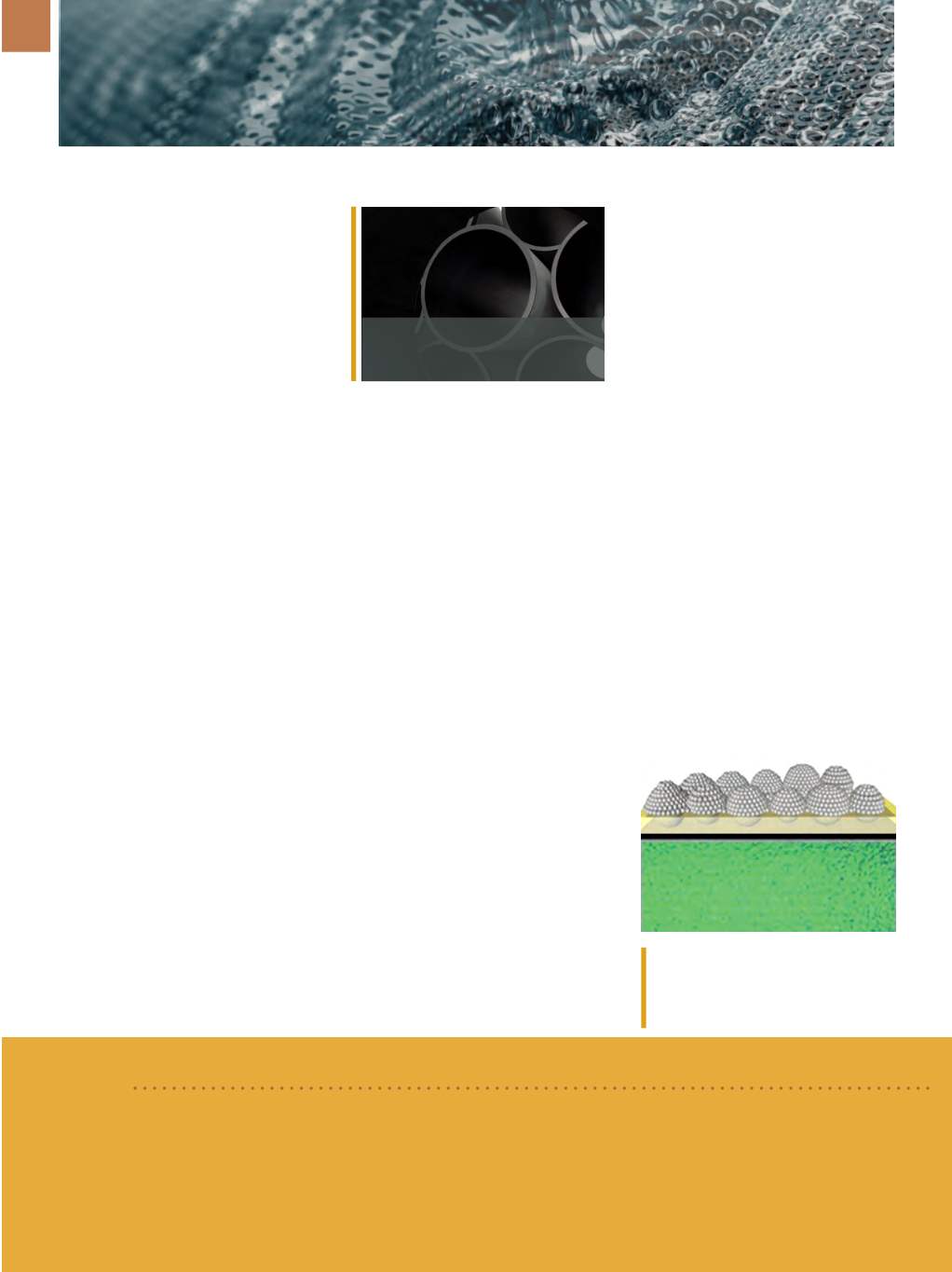

BUG EYES INSPIRE REFLECTIVE

MATERIALS

Retroreflective materials, includ-

ing some tapes and road paints, work

by bouncing light back toward the orig-

inal source, such as a car’s headlights,

making them bright and easy to see.

Existing retroreflectors are typically

made with glass microbeads andmicro-

prisms. Dyes, pigments, or plastic layers

are often added for color. However, they

tend to reduce light reflection and col-

ors can fade over time. Researchers at

the National Chung Hsing University,

China, and colleagues turned to the

compound eyes of insects for a newway

to address these limitations.

An array of glass microspheres was

evenly coated with smaller balls of sili-

ca, resulting in a brilliantly colored, ret-

roreflective material. Color can be ad-

justed by changing the size of the silica

crystals and brightness can be boosted

by adding layers. At 250 nm and 40 lay-

ers deep, crystals appear bright green

and reflect more light than commercial

coatings with no color. In addition to

boosting the brightness of objects for

safety reasons, researchers say that by

reflecting rather than absorbing light,

the material could be applied to build-

ings to reduce the urban heat-island

effect.

www.nchu.edu.tw/en-index.php.The structure of bug eyes (top) is inspiring

colorful reflective materials (bottom).

Courtesy of the American Chemical

Society.

New high temperature, internal pipe

coatings protect against corrosion.

Courtesy of Axalta.