A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J A N U A R Y

2 0 1 7

1 9

broken before removal. Salt cores, which

have appropriate strength and may be

dissolved after casting, can be applied

but have only achieved limited success

[3]

.

Therefore, coresmade of granular media

such as sand or similar materials repre-

sent a more promising research focus.

The key challenge is to develop

cores that are strong enough to with-

stand injection pressure (especially in

gating areas) and pressure intensifica-

tion during holding periods, thus allow-

ing generation of high integrity, hollow

structural castings. In addition, cores

must also break up easily after casting

for removal purposes.

Currently, suitable base core ma-

terials, binder materials, and surface

coating solutions are not available to

create an optimum core structure. How-

ever, inorganic binders are receiving

renewed attention from the automotive

industry. Further, knowledge of the in-

teraction between new core materials

and molten alloys is critically import-

ant. This interface is highly linked to

casting defect formation, which pre-

vents the successful manufacture of

high integrity structural components.

In such a defined project scope, closing

the knowledge gap through core devel-

opment is a priority.

CORE VERIFICATION

To prove the strong core concept,

two-step verification should be per-

formed that covers design and manu-

facturing of casting cores and imple-

mentation of cores to high pressure die

casting. A test component consisting of

a two-cavity test die featuring a simpli-

fied geometry with two cylinders of ap-

proximately 70 mm diameter, 200 mm

length, with wall thickness of 2 and 4

mm was selected. The test die with a

configuration of runners and overflows

A

utomotive components such as

engine blocks require internal

cavities or passages, either to

avoid costly machining or for weight

reduction. For example, engine cam-

shafts and crankshafts feature an

incorporated hollow structure for the

latter purpose. In order to manufac-

ture a component with internal cav-

ities during casting processes, cores

must be installed before the metal is

poured. A core is a replica—an inverse

one—of the internal features of the

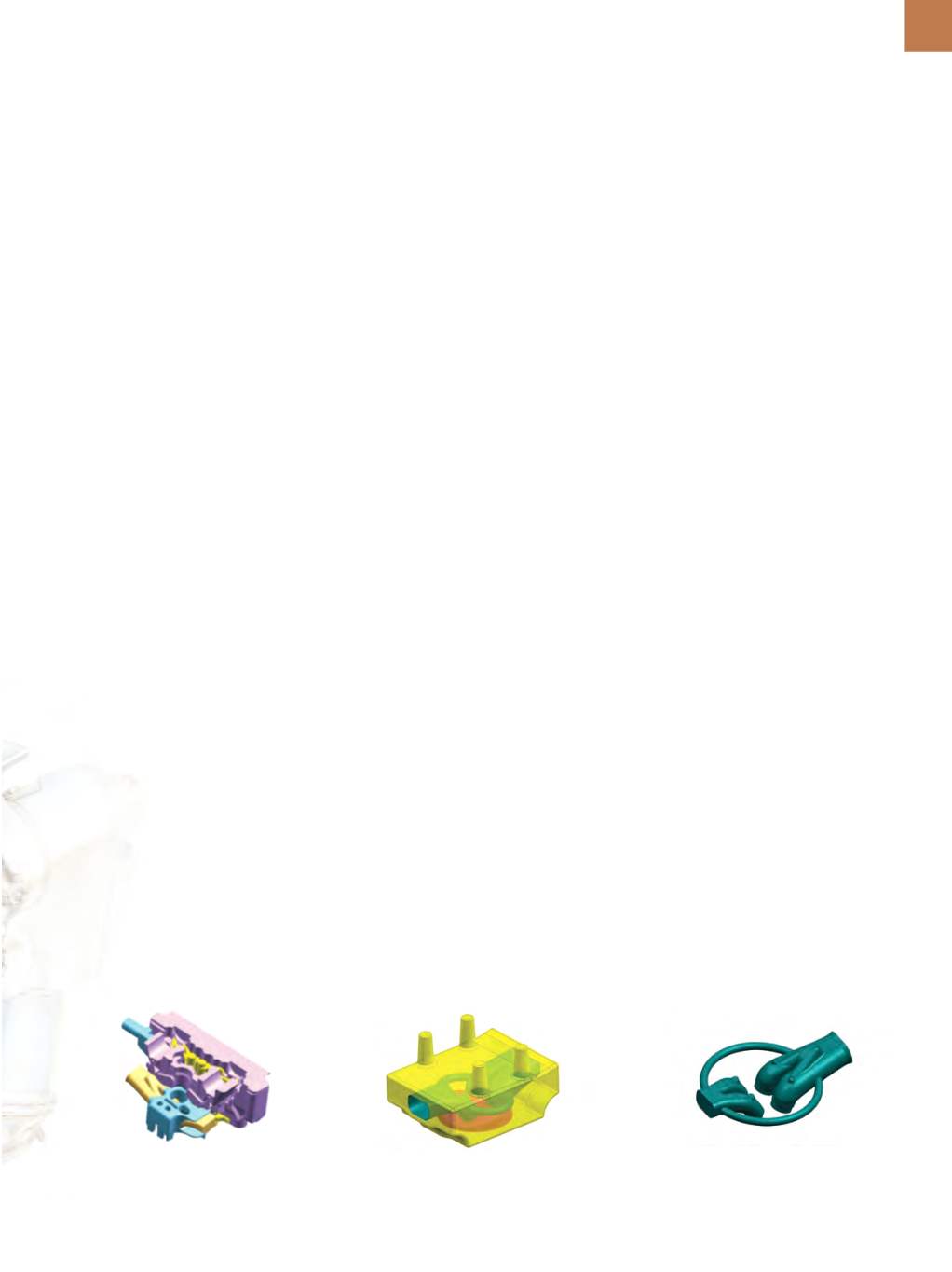

part to be cast (Fig. 1).

Depending on the casting tech-

nique, cores may either be completely

integrated into the casting die/mold

or loosely inserted there. After the

metal solidifies and the component is

released, the core must be broken, re-

moved from the product, and disposed,

although some applications exist for re-

usable cores. Depending on the particu-

lar method, when shifting from gravity

casting to low pressure and high pres-

sure die casting, core strength require-

ments vary asmelt pressure increases

[1]

.

This article addresses the deficiency of

existing technologies for manufacturing

certain lightweight automotive compo-

nents, in particular those with hollow

structures of complex geometry.

COMMERCIAL APPLICATIONS

Research on core casting encom-

passes a variety of core types and cast-

ing techniques. According to recent

developments, a sand core technique

produces automotive body frame

nodes by ablation casting

[2]

. The com-

bination of high properties and hollow

shapes make ablation cast nodes ideal

for a lightweight frame structure. Sand

cores create complex hollow internal

sections, further reducing weight. Cores

enable production of large, thin wall,

hollow shapes that are lightweight and

feature superior properties due to high

cooling rates. However, the most chal-

lenging application using strong/break-

able cores in high pressure die casting

has not been actively investigated.

Vehicle lightweighting with alumi-

num or magnesium alloys improves fuel

economy and reduces emissions. This

represents a complementary approach for

hybrid and fuel cell vehicles to increase ve-

hicle performance, particularly range. The

strategic vision to reduce vehicle weight

by up to 20% has not been achieved, in

part due to barriers in manufacturing

technologies. Development of a high-vol-

ume, low-cost casting process that uses

new generation casting cores will advance

manufacturing and enable production of

high-integrity components with full heat

treatment capabilities. Such a technolo-

gy would reduce component cost and in-

crease vehicle competitiveness.

TECHNICAL CHALLENGES

The design and manufacture of

casting cores remains a constant glob-

al challenge for foundries. This is due

in part to the growing complexity of

core shapes, greater strength require-

ments, and core removal techniques

that require new materials for the core

base and for binder and coating de-

velopment. There is also pressure to

develop better cores, which magnifies

the increasingly stringent environmen-

tal, health, and safety regulations. A

significant technology gap exists in the

application of cores for high pressure

die casting—the technique of choice for

large-scale manufacturing of structural

automotive components.

As a result, parts manufactured us-

ing current die castingmethods typically

do not contain complex internal passag-

es or cavities that require the core to be

Fig. 1 —

3D model shows core concept in casting: (a) part of complex geometry; (b) simplified test component with view of the part with

marked core inside; (c) essential core structure with a ring for assembly purposes. Due to the complex shape, the core cannot be removed from

the part without breaking.

a)

c)

b)