A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J A N U A R Y

2 0 1 7

2 3

The inverse pole figure color map

image in Fig. 3 shows the bainitic struc-

ture formed from a prior austenite grain

at 270°C for 7 h in 0.6 C steel. Colors

correspond to the crystallographic ori-

entation normal to the observed plane,

representing different crystallographic

variants. Black boundaries were drawn

where the misorientation angle is

greater than 10° or austenite is pres-

ent. A prior austenite grain was divided

by bainitic packets consisting of three

bainitic blocks where each block con-

tains a single variant of the bainitic lath.

RETAINEDAUSTENITE

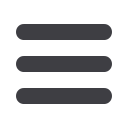

The nanoscale structure is not

exclusive to bainitic ferrite, as retained

austenite trapped between the plates

of ferrite also has a size <100 nm

(Fig. 2b)—so-called

nanofilms

. In low-

temperature bainitic structures, the

term

microblock

is used to denote

blocks of retained austenite >1000 nm,

while

submicron block

refers to those

between 100 and 1000 nm. Figure 4

shows the multiscale character of the

austenite in 0.6 C steel transformed at

250°C for 15 h.

Morphology and the chemical

composition are key factors controlling

the mechanical stability of austenite.

Carbon has the strongest influence on

enhancing mechanical stability

[6]

, while

at an atomic level, there is a strong cor-

relation between austenite feature size

and the amount of carbon retained in

solid solution (the smaller the size, the

higher the carbon level)

[8]

.

Transformation-induced plasticity

(TRIP) of austenite is thought to enhance

ductility if the austenite is moderately

stable against straining; for example,

when associated strain hardening ef-

fectively increases resistance to necking

and fracture. To this end, a wide distribu-

tion of sizes of retained austenite in the

microstructure (Fig. 4) leads to effective

variations of austenite stability, spreads

the transformation effect along strain-

ing, and postpones localization

[9]

.

CARBON SUPERSATURATION

IN FERRITE

Atom probe tomography shows a

high level of carbon in bainitic ferrite

without linear or surface defects, which

was over 10 times above what was

expected

[10]

. As transformation tem-

perature decreases, the carbon amount

remains high after transformation.

There are two possible explana-

tions of the abnormally high carbon

content in bainitic ferrite. The first

points toward a change in symmetry

from the conventional cubic unit cell

(bcc) into a tetragonal lattice (bct). The

second points to a high density of point

defects, particularly vacancies

[11]

.

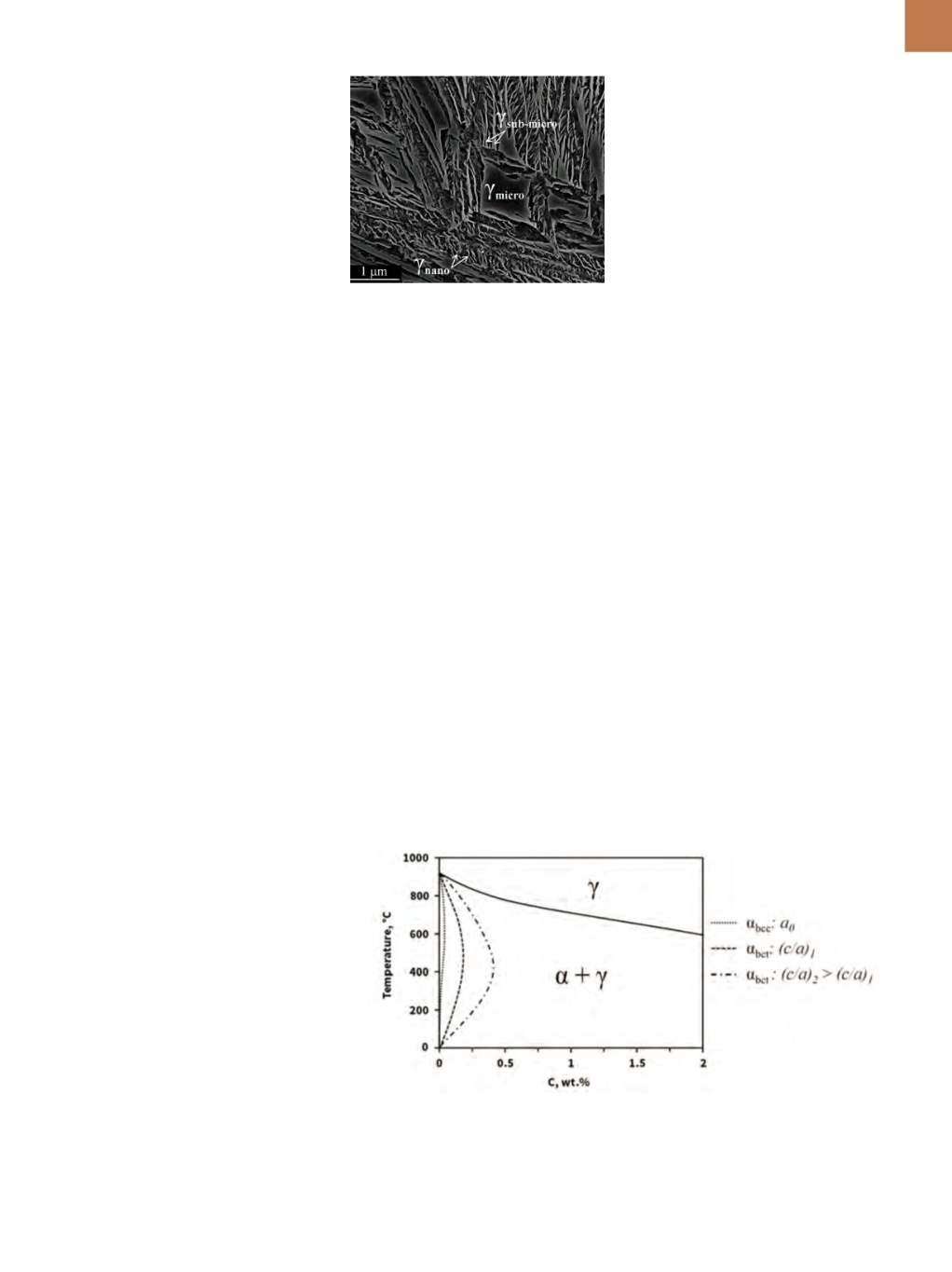

Synchrotron radiation and x-ray

diffraction experiments show a tetrag-

onal or slightly orthorhombic unit

cell of bainitic ferrite capable of hold-

ing the excess carbon

[12]

. Likewise,

first-principles calculations prove that

when tetragonal ferrite is in para-equi-

librium with austenite, it has a much

greater solubility for carbon than is the

case for cubic ferrite under the same

conditions

[13]

. In this scenario, the ret-

rograde shape of the α/α+γ equilibrium

phase boundary in the Fe–C phase dia-

gram is displaced toward higher car-

bon solubility in ferrite providing that

tetragonality (

c/a

ratio) increases as

seen in Fig. 5.

On the other hand, specific inter-

stitial lattice sites near defects in bain-

itic ferrite provide lower-energy sites

for carbon than the regular interstitial

lattice positions, which would result

in an increased solubility of carbon in

the ferrite. Computational calculations

support this increased solubility of car-

bon in cubic iron caused the formation

of vacancy-carbon complexes

[14]

. How-

ever, further experimental evidence of

this unusually high density of vacancies

in bainitic ferrite is required.

SUMMARY

Nanostructured bainitic steels

have been theoretically designed

and manufactured using conventional

industrial practices, achieving mechan-

ical properties never recorded before in

bainite structures. Bainitic steel micro-

structures consist of extremely fine

plates of carbon-supersaturated ferrite

and retained austenite. The increased

solubility of carbon in ferritemight form

Fig. 4

—

SEM of microstructures in 0.6 C

steel obtained by isothermal transforma-

tion at 250°C for 15 h.

Fig. 5

—

Fe–C binary phase diagram considering only ferrite and austenite show the effect of

tetragonal ferrite (

α

bct

) with different c/a ratios on the

α

/

α

+

γ

equilibriumphase boundary com-

pared to cubic ferrite (

α

bcc

).