A D V A N C E D M A T E R I A L S & P R O C E S S E S | J A N U A R Y 2 0 1 7

2 6

SYMPOSIUMHIGHLIGHTS

In “The Age of Bessemer Steel,”

AM&P

editor-in-chief Frances Richards

presented the story behind the devel-

opment of the revolutionary processing

pathway that simultaneously reduced

the cost and increased the quality of

steel, fueling the Industrial Revolution

and enabling reliable rail transport

across continents. Based on the arti-

cles, “Metallurgy Lane: The Age of Steel”

(Parts I and II) published by ASM life

member Charles Simcoe in this mag-

azine, the talk highlighted that both

Henry Bessemer (of Sheffield, England)

and WilliamKelly (of Kentucky) simulta-

neously and separately (around 1850)

discovered that bubbling air through

molten blast furnace cast iron removes

carbon, thus enabling efficient steel

production.

Along with Robert Mushet’s dis-

covery that the addition of manganese

reduces “hot-shortness” by manganese

sulfide formation, these developments

allowed William Kelly to open a small

plant using his process in Wyandotte,

Mich., in 1863. At the same time, Alexan-

der Lyman Holley was able to navigate

the patent space in the U.S. and build the

first Bessemer steel plant in Troy, N.Y., in

1865. By the end of the century, Andrew

Carnegie became the leading producer

of steel and the industrial and techno-

logical revolution was at full steam.

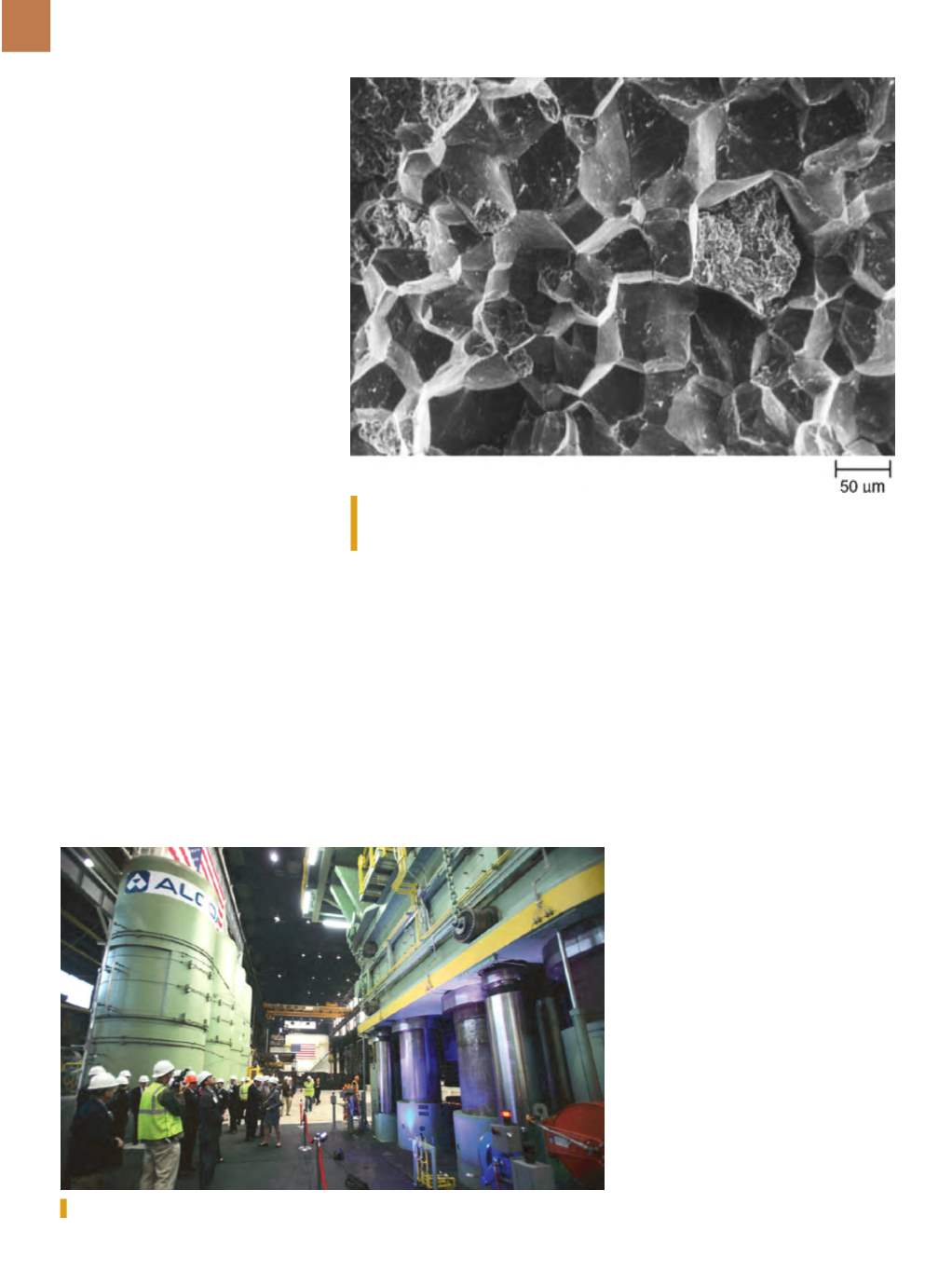

Jon Tirpak, FASM, immediate past

president of ASM, then spoke about

the technology development that

enabled the move from hammer forg-

ing of steels in the years prior to World

War II to hydraulic press use to control

strain rates. This development allowed

light metal forging and enabled the

burgeoning aerospace industry. After

the war, technologies originally devel-

oped in Germany were transferred to

the U.S. and U.S.S.R., and a race to pro-

duce the largest presses to enable the

production of large aluminum, magne-

sium, titanium, and steel components

ensued. ASM International recognized

the historical significance of six of these

heavy hydraulic presses worldwide in

2013 by naming them ASM Historical

Landmarks.

Press size correlates directly to

the size of components that can be pro-

duced, which determines the largest air-

craft size possible. In a worldwhere new

technologies for manufacturing compo-

nents are being developed, including

additive manufacturing, this talk high-

lighted the critical need to teach and

develop expertise in processes such as

forging. Unlike many other techniques,

materials produced by forging feature

refined grain structures and substantial

mechanical work, and allow designers

flexibility and opportunities to reduce

weight in large structural components

where properties and repeatability are

critical to performance.

The third speaker, Prof. Rian Dippe-

naar from the University of Wollongong,

discussed development of high-quality

lenses that enabled optical metallogra-

phy use, which in turn allowed for iden-

tification of phases and constituents in

microstructures, transforming metal-

lurgy. Initial observations using optical

Alcoa’s 50,000 ton press, Cleveland, refurbished in 2012.

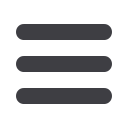

Brittle intergranular fracture along prior austenite grain boundaries in carbon steels

quenched and tempered tomartensite, known as quench embrittlement.