A D V A N C E D M A T E R I A L S & P R O C E S S E S | J A N U A R Y 2 0 1 7

3 0

encounters the interface between two

materials, a portion is reflected back to

the transducer as an echo signal, while

another portion is transmitted across

the interface and travels deeper into

the sample, where it may encounter an-

other interface and send back another

echo signal. Any interface between a

solid and air or another gas is an excep-

tion as at these interfaces, nearly all of

the ultrasound is reflected as an echo

signal. None is transmitted across the

interface. The echo signal from a solid-

to-air interface has the highest possible

amplitude and therefore appears bright

white in monochrome acoustic images.

The color of solid-to-solid interfaces de-

pends on the physical characteristics of

the two materials at the interface, and

ranges from light gray (high amplitude)

to dark gray (low amplitude).

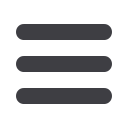

One region of the cell was acous-

tically imaged (Fig. 2). Four equally

spaced trenches, all of which should be

filled with aluminum paste, are marked

by colored bars. Linear features parallel

to the trenches are at a different depth

and are not trenches.

The left trench marked by red bars

is bright white, meaning that it is voided

for the entire length shown here. During

screen printing, the trench depth is not

completely filled with aluminum paste.

The void that lies between the die and

paste prevents electrical contact. The

trench marked by green bars is dark—

meaning it is completely filled. This is

the desired condition that allows elec-

trical contact between the silicon and

aluminum paste. The two trenches

marked by blue bars are partially filled

and partially voided.

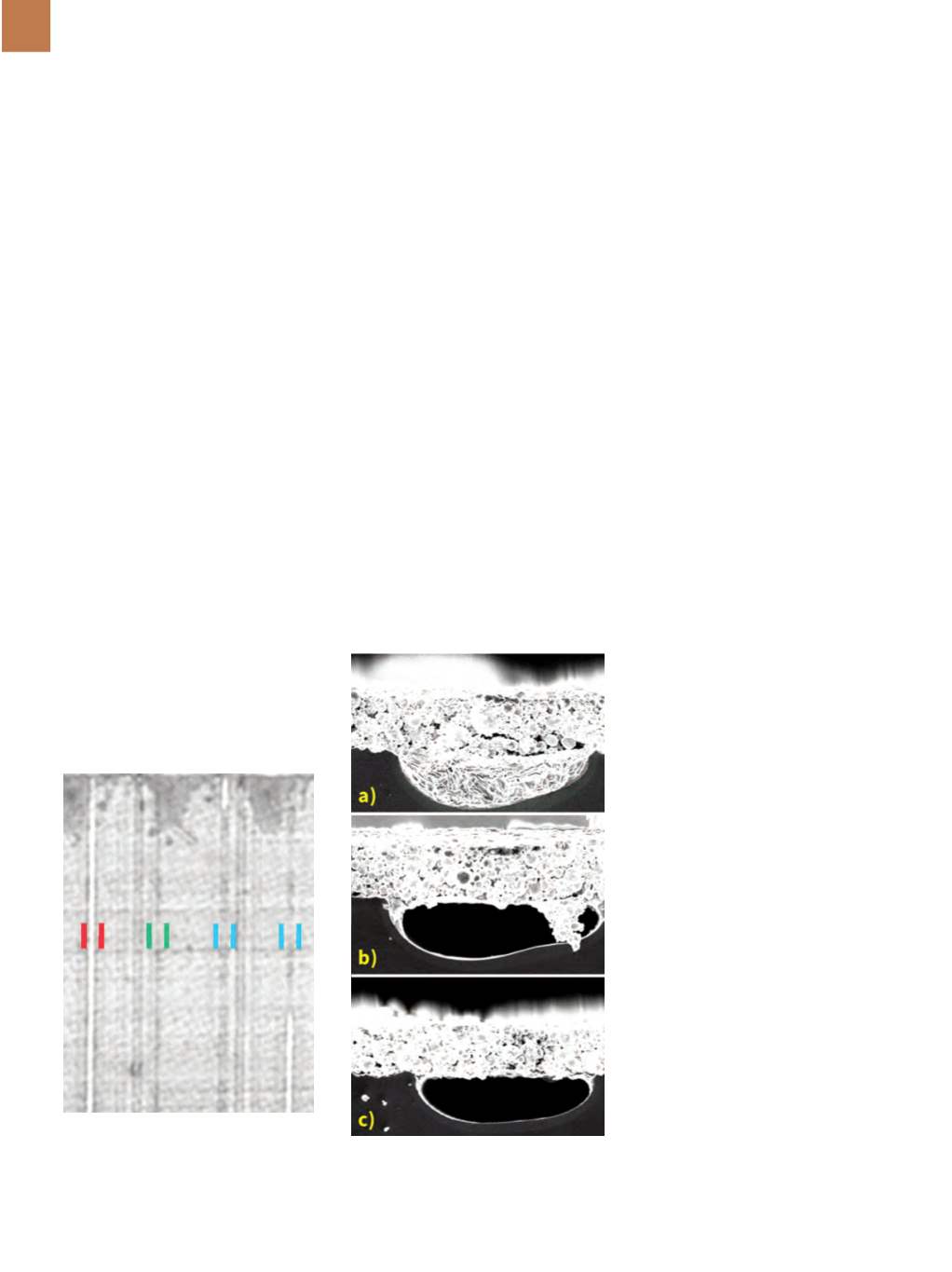

Throughout the cell, comparing

the dark vertical features in the elec-

troluminescence image in Fig. 1 to the

trenches acoustically imaged in Fig. 2

reveals that only some of the acous-

tically visible voids also appear in the

electroluminescence image. The cell

was next sectioned through some of the

trenches, and the trench cross-sections

were viewed by a scanning electron mi-

croscope (SEM). Typical results are seen

in Fig. 3.

In Fig. 3a, the rounded trench pro-

file in the SEM image shows that the

trench is completely filled by alumi-

num paste. Dark regions in the trench-

es in Fig. 2 would appear much like

this in cross-section. In this figure, the

aluminum layer bonded to the back-

side surface lies just above the trench.

Electrical contact in this portion of this

trench is acceptable.

In Fig. 3b, the only area of the

trench that has been filled is at the

right. The efficiency of such a small fill is

unknown, but it is likely to be limited. In

Fig. 3c, the entire trench is voided and

there is likely no electrical contact. In an

acoustic image, this trench (along with

that in 3b) would appear bright white.

CONCLUSION

Next steps in this research will in-

clude precise characterization of the

relationship between the acoustic ap-

pearance of a trench and the degree of

electrical contact between the alumi-

num paste and the solder. This infor-

mation will permit better control over

PERC production, maximize cell effi-

ciency, and make it possible for PERC

crystalline silicon solar cells to fulfill a

prediction by the International Technol-

ogy Roadmap for Photovoltaic that they

will capture 45% of worldwide market

share by 2024.

~AM&P

For more information:

Steve

Martell is manager, advanced applica-

tions support, Sonoscan Inc., 2149 E.

Pratt Blvd., Elk Grove Village, IL 60007,

847.437.6400,

info@sonoscan.com,

www.sonoscan.com.

*C-SAM is a registered trademark

of Sonoscan Inc.

Fig. 3 —

SEM images of cross sections

through filled, partly filled, and unfilled

trenches.

Fig. 2 —

C-SAM imaging illustrates the

difference between filled (dark) trenches

and trenches that are partly or entirely

unfilled (white).