A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J A N U A R Y

2 0 1 7

2 7

metallography were open to interpreta-

tion and each successive improvement

in lens quality increased available mag-

nifications, which further clarifiedmicro-

structural details.

Dippenaar related these devel-

opments to current work using laser-

scanning

confocal

microscopy

to

observe high-temperature microstruc-

ture development in-situ. Using this

technique, important changes in micro-

structure such as solidification, and

diffusional and displacive solid-solid

phase transformations in real time, may

be observed. Laser-scanning confocal

microscope development now allows

unprecedented observation of these

phenomena as they happen, and inter-

pretation of these results requires many

years of study moving forward. The abil-

ity to characterize materials at higher

resolutions and in real processing envi-

ronments is a critical area where techno-

logical developments promise to unveil

previously misunderstood fundamen-

tals of metallurgy.

An area where improved char-

acterization will continue to enhance

understanding and result in vastly im-

proved performance is steel processing.

Prof. Emeritus George Krauss, FASM,

Colorado School of Mines, gave an ex-

ample by discussing the phenomena of

steel embrittlement. Several conditions

exist where low ductility is observed in

steels, including quench cracking, tem-

per embrittlement, tempered marten-

site embrittlement, hydrogen embrit-

tlement, and quench embrittlement.

There was a focus on quench embrit-

tlement, which results in intergran-

ular fracture on prior austenite grain

boundaries.

Krauss summarized the efforts

over the past 40 years to understand

low toughness that occurs in quenched

and tempered steels with carbon levels

of approximately 0.5 wt% and above.

Through high quality characterization

by various methods, it has been shown

that cementite formation on prior aus-

tenite grain boundaries is associated

with this reduction in ductility, and that

alloying elements such as phosphorous

further aggravate the problem. Over

time, a map of tempering temperature

vs. carbon content has been developed,

showing that quench embrittlement

occurs only in high carbon steels tem-

pered at low temperatures. Understand-

ing the mechanisms behind phenomena

such as quench embrittlement allow the

use of high strength steels with micro-

structures designed to avoid conditions

where brittle failure would occur.

The

fifth

speaker,

Robert

Glodowski

of

RJG

Metallurgical

LLC, highlighted the importance of

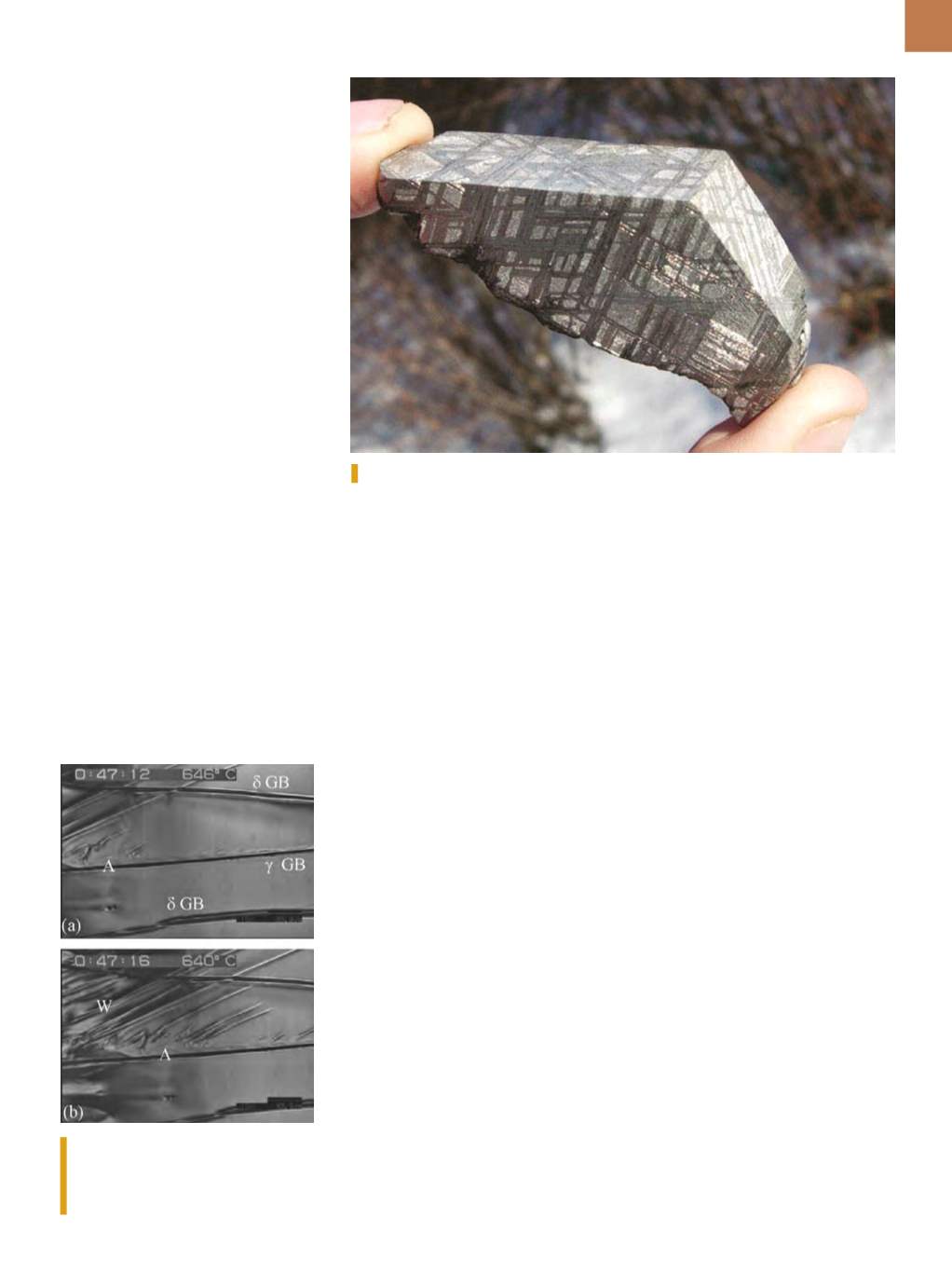

Observation of formation of Wid-

manstätten ferrite (W), from ferrite

allotriomorphs (A) during cooling from

austenite (

γ

) in an Fe-C alloy.

understanding microstructural devel-

opment as a function of processing in

his presentation, “The Evolution of Fer-

rous Grain Size Control: Standards and

Practice.” In the late 1950s, it was often

necessary to specify use of alloying for

austenite grain size control to ensure

that hot rolled steels were heat treat-

able, and that the quality of the result-

ing products was satisfactory. However,

as steelmaking and rolling processes

steadily improved, the need for grain

size control via alloying and prescribed

processing procedures for as-rolled

steels disappeared.

Improved processing technolo-

gies enabled controlled thermal and

mechanical rolling techniques, which

eliminated the need to separately roll

for shape and heat-treat for proper-

ties. Because the fine-grained austenite

quality requirement is often still cited

in standards, the perception that they

are still needed remains, even though

they do not benefit modern as-rolled

steels. Grain-refining alloy additions

and associated testing increases the

steelmaking process cost, and may in

fact cause other quality problems and

an unwarranted sense of security to the

user. This is another example where a

fundamental understanding of micro-

structural development as a function

of processing is imperative to enable

manufacturing with the highest possible

quality at the lowest possible cost.

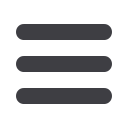

Cross-section of meteorite shows 3Dmicrostructure formed over millions of years.