A D V A N C E D M A T E R I A L S & P R O C E S S E S | J A N U A R Y 2 0 1 7

2 2

The strength and hardness of the

structure are mainly due to the volume

fraction of the ferritic phase (V

α

), while

plate thickness is responsible for further

strengthening. Accordingly, hardness

and yield strength values correlate well

with the ratio V

α

/t as shown in Table 1.

Strength residue—after accounting for

bainitic-ferrite plate thickness—comes

from dislocation forests, the intrinsic

strength of the iron lattice, and solution

strengthening

[1]

. Therefore, at the same

transformation temperature, higher

carbon grades (1.0 C and 0.8 C) exhibit

superior tensile properties, with UTS

values greater than 2 GPa.

Microstructural parameters in

terms of phase volume and scale fail to

predict elongation values. For instance,

ductility at the lowest transformation

temperature is relatively low for all

compositions. However, sensitive and

unsystematic improvement occurs when

transforming at 250°C despite the fact

that microstructural parameters do not

significantly change. Retained austenite

mechanical stability might be the key to

the ductility in those microstructures

[6]

.

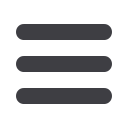

NANOSCALE FERRITE

Transmission electron microscopy

(TEM) micrographs of 0.6 C steel trans-

formed at 220°C for 22 hours are shown

in Fig. 2. Some bainitic ferrite plates are

exceptionally long and thin (~50 nm),

with a structure consisting of an inti-

mate mixture of ferrite and austenite

(Fig. 2).

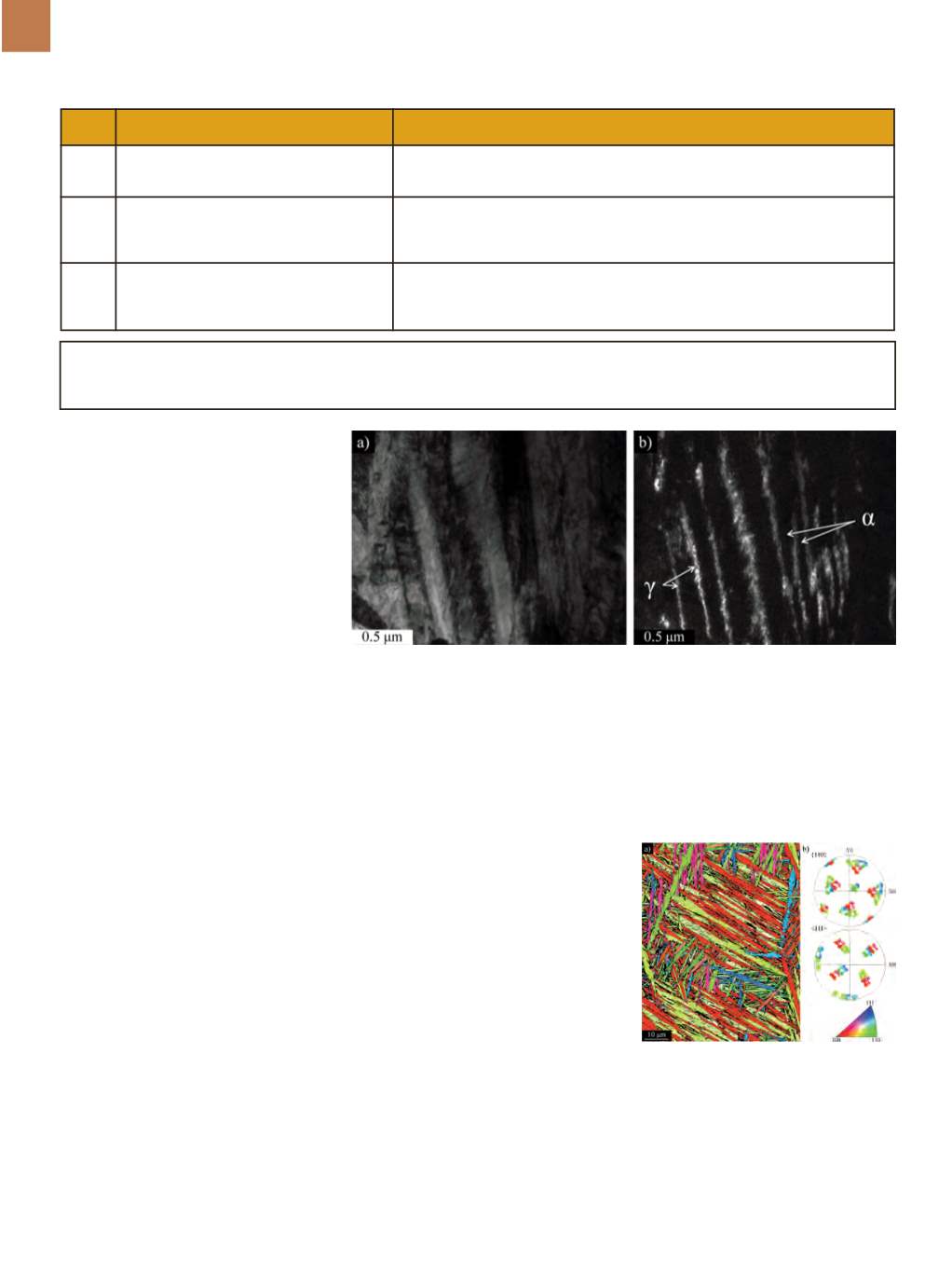

Nearly all ferrite laths in a bainite

sheave have the same crystallographic

orientation. In displacive transforma-

tions, it is generally assumed that the

close-packed {111} plane of austenite

(face-centered cubic, or fcc) is parallel

to a {110} plane of the bainitic ferrite

(body-centered cubic, or bcc). In nano-

bainitic steels, most bainitic plates

and parent austenite interfaces have

an orientation relationship (OR) close

to the Nishiyama–Wassermann (N-W),

{111}γ||{110}α with <110>γ||<001>α

[7]

.

From a single austenite crystal, 12 crys-

tallographic variants can be formed

with an N–W orientation relationship

due to the symmetry of cubic systems.

A crystallographic packet is a group of

crystallographic variants with a com-

mon {111} austenite plane. Each bain-

itic packet can be divided into bainitic

blocks of the three variants of the N–W

relationship satisfying the same paral-

lel plane relationship. This causes the

obtained microstructure to be highly

misoriented, with a wide variety of

microstructural barriers.

ID

Chemical composition, wt%

T ,°C Time, h

V

γ

, % t,

nm

V

α

/t,

Hardness,

nm

-1

HV30

1.0 C

1.00 C, 2.90 Si, 0.75 Mn, 0.50 Cr

220

22

36

28

2.29

650

250

16

34

39

1.69

625

220

22

22

32

2.44

710

0.8 C

0.88 C, 1.54 Si, 0.69 Mn, 0.50 Cr

250

16

18

38

2.16

659

270

7

24

36

2.11

615

0.6 C

0.65 C, 1.60 Si, –1.25 Mn, 1.60 Si, 1.75 Cr,

220

22

24

38

2.00

643

0.15 Mo, 0.12 V

250

15

22

37

2.11

600

270

7

32

48

1.44

554

KEY

T: transformation temperature; Time: transformation time;

V

γ

volume fraction of austenite;

t

: bainitic ferrite plate thickness;

V

α

/t

, ratio

between the volume fraction of bainitic ferrite and the plate thickness.

Fig. 2

—

TEM of microstructures obtained at 220°C for 22 h in 0.6 C steel. a) Bright-field image.

b) Corresponding dark-field image of retained austenite films where bainitic ferrite plates lie

between.

Fig. 3

—

a) Inverse pole including a single

prior austenite grain of 0.6 C steel trans-

formed to bainite at 270°C for 7 h. The black

thin lines represent either misorientation

angles greater than 10° or austenite films. b)

{011} and <111> pole figures representing all

orientations of bainite laths corresponding

to (a), showing the typical N-W pattern.

TABLE 1 —SECONDGENERATIONBAINITIC STEEL NANOSTRUCTURE PROPERTIES