A D V A N C E D M A T E R I A L S & P R O C E S S E S | J U L Y / A U G U S T 2 0 1 6

2 2

TECHNICAL SPOTLIGHT

DESIGNING THIRD GENERATION

ADVANCED HIGH-STRENGTH STEEL

FOR DEMANDING AUTOMOTIVE

APPLICATIONS

By effectively mitigating the historical paradox between strength and

ductility, a new alloy enables an entire family of automotive sheet

steel to meet today’s lightweight automobile requirements.

T

here has long been a struggle

among

materials

scientists

over the paradoxical relation-

ship between a metal’s strength and

ductility. The inability of traditional

materials to meet the dual demands

of both high-strength and easy form-

ability has opened the door for alter-

native materials in applications such

as automotive lightweighting. Existing

advanced high strength steels (AHSS)

require a tradeoff: High strength parts

can either be designed using more

limited geometries or produced using

more expensive methods such as hot

stamping. Both approaches are less

than ideal.

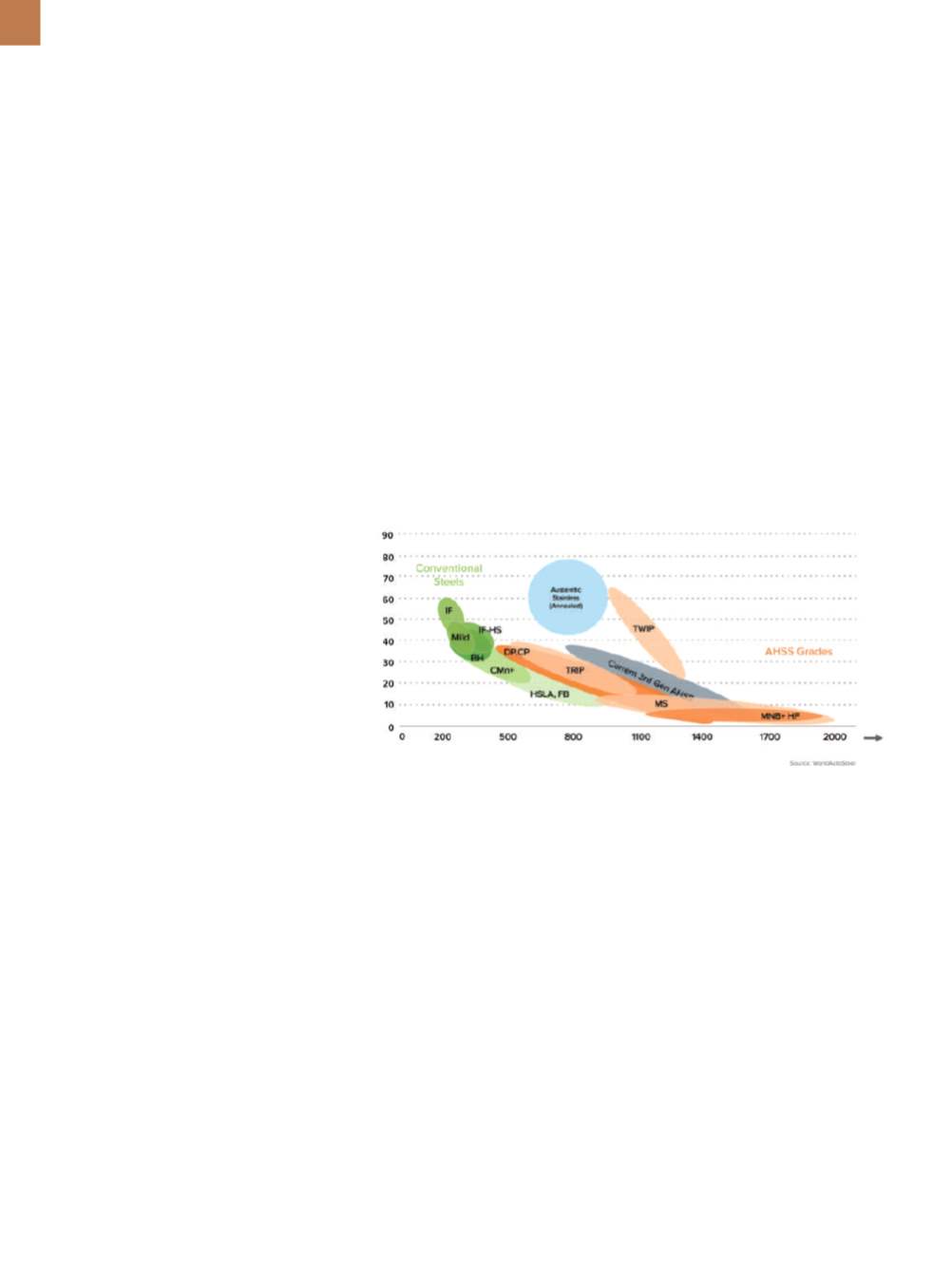

The existing pattern of strength

and ductility relationships in auto-

motive steel alloys is demonstrated

by the well-known

banana plot

from

WorldAutoSteel (Fig. 1). Conventional

steels (green) represent the backbone

of the global economy—they are strong

enough for many applications and

demonstrate high formability, which

allows them to be inexpensively shaped

for a wide variety of uses.

The known AHSS (orange) trade

much of that formability for increased

strength. The one exception is twinning

induced plasticity (TWIP) steels, which

seemed to solve the problem but are

limited in use due to multiple factors

including delayed fracture. Austenitic

Fig. 1 —

WorldAutoSteel banana plot illustrates steel grades used in automobiles.

stainless steels present another option

for achieving the desired properties,

but their cost is prohibitively expensive

for automotive body structures as well

as many other applications.

THIRD GENERATION

AHSS PROPERTIES

Automakers

have

established

properties for third generation AHSS to

meet industry needs (Fig. 2). A number

of ways to design new steels to over-

come existing challenges are being

explored, including variants on quench,

partitioning, and tempering. However,

these types of steels typically cannot

deliver total elongation higher than

20%, which is inadequate for forming

advanced automotive parts.

A different approach to overcom-

ing the existing strength and ductility

paradox to achieve the desired prop-

erties required for third generation

AHSS is being taken at NanoSteel,

Providence, R.I.

[1]

. Conventional steel

constituents in novel ratios are used

while new mechanisms are harnessed

for creating the nanoscale structure.

This approach results in a targeted for-

mation called a

mixed microconstituent

structure

, enabling the sheet to exhibit

the desired AHSS properties.

In the new structure, two distinct

microconstituents act synergistically

on a local level during deformation.

By varying the volume fraction of the

microconstituents in the final sheet

material, many different outcomes for

Elongation, %

Tensile strength, MPa