A D V A N C E D M A T E R I A L S & P R O C E S S E S | J U L Y / A U G U S T 2 0 1 6

2 0

(Fig. 3). Wall thicknesses down to

approximately 0.5 mm are possible and

implants are typically sterilized with

ethylene oxide prior to implantation.

MECHANICAL PROPERTIES

For many orthopedic sports med-

icine applications, the implant’s me-

chanical properties are critical both

immediately after surgery and for the

entire healing period. After the pa-

tient is fully healed, implants should

generally no longer be load bearing.

With BR, adding the bioceramic filler

compromises the inherent strength

of the parent polymer, but not to an

unusable degree. For example, suture

anchors made from BR are rough-

ly 87% of the strength of the same

size suture anchors made from PEEK

(Fig. 4). However, in internal tests,

the tensile modulus is higher for BR

(2.6 GPa) compared to PLLA (2.0 GPa).

In addition to decreasing strength

and increasing modulus,

β

–TCP af-

fects ductility, as might be expected.

Interestingly, internal testing shows

a significant improvement in ductility

as the material is brought from room

temperature to body temperature. In

fact, the engineering strain at fracture

nearly doubles to approximately 9%

over the course of this 14°C tempera-

ture increase. Over the same tempera-

ture rise, maximum stress drops from

72.4 to 53.8 MPa (Fig. 5).

PRECLINICAL STUDY

Despite a long history of clini-

cal use for all three components of BR

(

β

–TCP, PLLA, and PGA), a preclinical

study was performed on the specific

blend of these components in BR. A

femoral transcortical model using Bea-

gle dogs was setup in which cylindrical

rods of BR and PLLA (as a control) were

implanted into holes drilled in the ani-

mals’ legs. Bone integration was stud-

ied at set time frames up to 24 months

after surgery

[5]

.

As expected, PLLA rods exhibited

little to no absorption at three and

10 months; at 18 months, absorptive

changes were graded as minor to mod-

erate. At 24 months, the absorption

profile of all eight implants was still

graded as moderate.

The BR rods were also fully

intact at three months, but exhibited

minor absorption characteristics at 10

months. By 15 months post-op, the rods

had significant fissures throughout,

although the majority of the BR was

still present. At 18 months, the BR rods

were mostly absorbed and replaced

by a combination of new bone at the

periphery and a mixture of macro-

phages andmesenchymal cells near the

center. By 24 months, the BR material

was 97-99% absorbed

[5]

. This volume

was completely filled with new bone

in four cases and 75-87% filled with

new bone in the remaining four cases

(Fig. 6). Newly formed bone was visu-

ally normal in all respects. This study

provided direct in vivo evidence of

the biocompatibility and appropriate

absorption profile for this material

[5]

.

SUMMARY OF CLINICAL DATA

Following the launch of the first

orthopedic implant made of BR in 2004,

multiple clinical series describing the

osteoconductivity of this material have

been published in the peer-reviewed

orthopedic sports medicine literature,

including at least four in the past three

years

[6-9]

. In total for these studies, 167

patients were followed for between two

and three years after either ACL recon-

struction, repair of Bankart lesions fol-

lowing shoulder instability, or rotator

cuff repair surgery. Radiographic and

magnetic resonance imaging (MRI)

evidence suggest that BR is nearly

Fig. 2 —

Scanning electron micrograph of

Biocryl Rapide (270x).

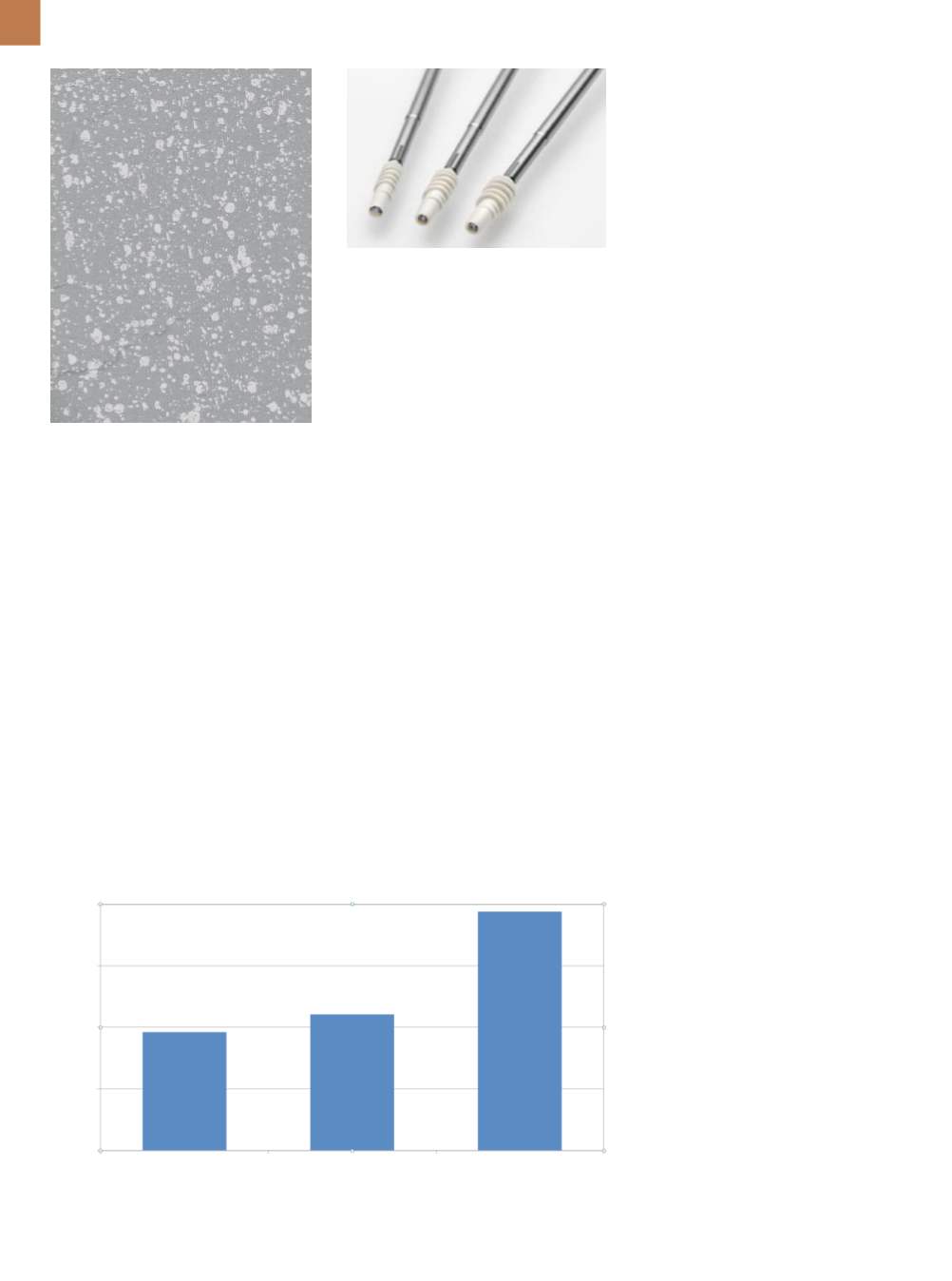

Fig. 3 —

Suture anchors injection molded

fromBiocryl Rapide loaded onto stainless

steel inserters.

Fig. 4 —

Relative pull-out strength of similar suture anchors made of Biocryl Rapide (left), PEEK

(middle), and 6Al-4V titanium (right).

Anchor Pull-Out Strength, N

BR PEEK Ti

400

300

200

100

0

Load, N