A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J U L Y / A U G U S T

2 0 1 6

1 7

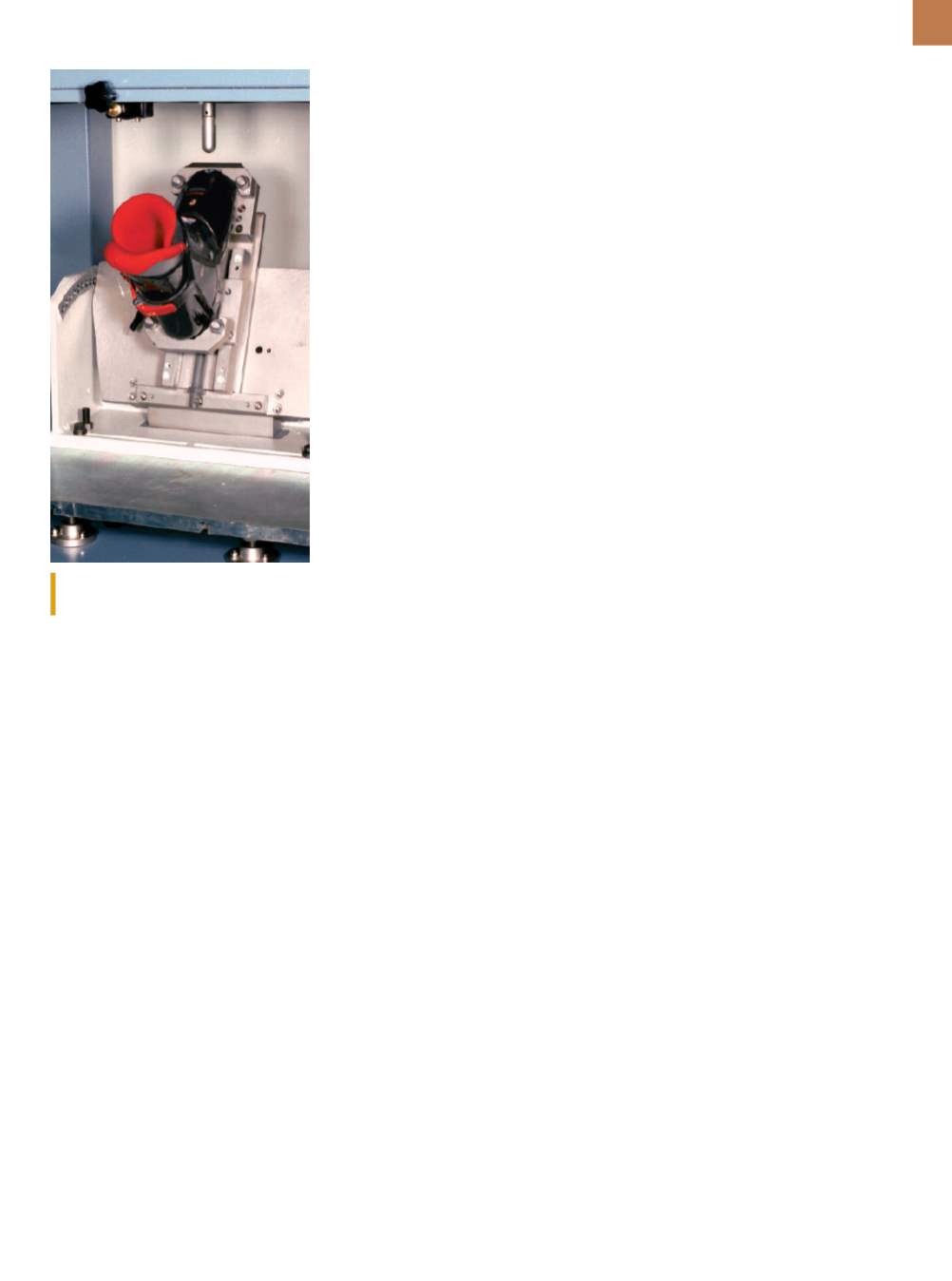

Impact testing of a ski boot determines

fracture properties.

B

iomechanics

applies established

mechanical principles to bio-

logical structures and functions

as they relate to the body in motion.

By applying the laws of mechanics to

the human body, engineers can ana-

lyze professional athletes and develop

materials that will enhance perfor-

mance and help prevent sports-related

injuries.

Many sporting goods manufac-

turers pay close attention to material

performance, especially with regard

to footwear, clothing, and protective

equipment. Even with improvements

that help minimize injury risk, damage

and wear often still occur. Some of the

most common ligament and tendon

tears, along with broken bones, occur

during sports-related activities. There

is a rising demand from both profes-

sional and recreational athletes to

improve injury-related recovery times

and increase therapy options. For

sports and recreation equipment man-

ufacturers and sports medicine clini-

cians, mechanical testing is essential

to optimize material performance,

minimize injury, and improve recovery

outcomes.

ATHLETIC FOOTWEAR TESTING

Footwear is one of the most

important aspects of all athletic

endeavors, with significant resources

invested into the design of high-

performance

footwear.

Therefore,

testing plays an important role in ath-

letic shoe research and development

efforts. For example, engineers often

investigate the impact and rebound

performance of different materials

and structures. Intense activities such

as long-distance running, soccer,

and basketball often place excessive

mechanical loads on footwear that can

result in impact forces of more than

10 times an athlete’s body weight.

Today’s athletic wear manufac-

turers are designing and developing

shoes with high-performance soles,

which often incorporate air cushion-

ing, gel-filled capsules, or both. One

type of mechanical test manufacturers

use to guide design is

energy return

.

Mechanical fatigue testing evaluates

the behavior of different parts of the

sole and helps identify parameters such

as dynamic stiffness and the ability to

absorb energy.

Some fatigue testing machines

allow users to import complex wave-

forms to simulate a runner’s gait. Deter-

mining the mechanical performance of

complex viscoelastic materials in shoe

soles is critical to improving athletic

footwear design. Optimizing this per-

formance helps reduce ankle, knee, and

hip stress, and ultimately enables ath-

letes to move faster and avoid injury.

TESTING ENHANCES

PROTECTIVE GEAR

Sports safety and sports-related

injury are hot topics, especially as they

pertain to high-impact activities such

as football and hockey. In these sports,

the dual objective of equipment suppli-

ers is to both enhance performance and

minimize injury. In recent years, hockey

and football equipment manufacturers

have increased their impact testing and

static testing to ensure that protective

gear functions correctly.

For example, equipment designed

to reduce bodily impact, such as shoul-

der and body padding, is tested to deter-

mine the amount of energy absorbed.

Also, because protective materials are

often bulky and cumbersome for ath-

letes towear andmaneuver in, manufac-

turers are constantly looking for lighter

and more breathable materials that do

not sacrifice impact resistance.

Protective gear, such as helmets,

is also impact tested to determine the

strength of the outer helmet shell, inner

cushioning, and strap. One key compo-

nent of helmet design is the ability to

distribute impact shock. The amount

of force transmitted through the helmet

can be quantified using multiple strain

gauges mounted to both a dummy

headform and external helmet. Today’s

helmet design has drastically improved

with an abundance of resources contin-

ually invested and greater awareness

of head health issues. Helmets are now

multilayered and combine impact-ab-

sorbing pliable materials to reduce

concussions and protect athletes from

impact-related injuries.

BIOMATERIALS DEVELOPMENT

AND TESTING

While impact-related injuries are

common in professional football and

hockey, some of the most prevalent

injuries among other professional

athletes and recreational players are

muscle pulls and tears, especially in

knees and shoulders. A tear to the

anterior cruciate ligament (ACL) is one

of the most severe sports injuries and

requires surgery to restore. Proper

repair of an ACL tear may require sev-

eral months of healing depending on

the patient’s age and health. Unfortu-

nately, this injury is sometimes serious

enough to shorten an athletic career.

Many biomedical companies are

focusing on ways to improve musculo-

skeletal healthcare. Not only are they

investing in creating better equipment

for surgeons and doctors, but they

are also investigating new biomateri-

als. A major initiative of biomaterials